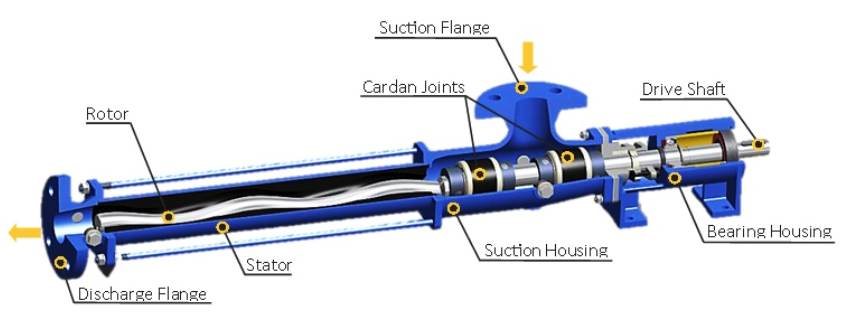

Progressive Cavity Pump Diagram

A progressive cavity pump, also known as a helical rotor pump or a mono pump, is a positive displacement pump that consists of a helical rotor and a stator. The rotor rotates eccentrically within the stator, creating cavities that transfer fluid from the suction side to the discharge side.

The Description of Progressive Cavity Pump Diagram

A progressive cavity pump, also known as a helical rotor pump or a mono pump, is a type of positive displacement pump that operates based on the principle of transferring fluid through the combined rotation of a helical rotor and a stator. The pump consists of a single helical rotor, typically made of metal, which rotates eccentrically within a double-threaded stator made of an elastomeric material such as rubber. As the rotor turns, cavities are formed between the rotor and the stator, enabling the continuous transfer of fluid from the suction side to the discharge side.

The Application of Progressive Cavity Pump Diagram

Progressive cavity pumps find extensive applications in various industries for handling fluids with high viscosity, solids content, or delicate shear-sensitive properties. Some common areas of application include:

Oil and Gas: Progressive cavity pumps are frequently used for pumping crude oil, drilling mud, produced water, and other viscous fluids encountered in upstream and downstream operations.

Food and Beverage: These pumps are suitable for transferring food products like dough, sauces, creams, and viscous ingredients during manufacturing processes.

Chemical and Petrochemical: Progressive cavity pumps are utilized for pumping different chemicals, such as acids, solvents, adhesives, resins, and polymers.

Wastewater Treatment: They are employed in wastewater treatment plants for transferring sludge, thickened biosolids, and other high-viscosity waste materials.

The Features of Progressive Cavity Pump Diagram

- Gentle Fluid Handling: Progressive cavity pumps are known for their gentle fluid handling capabilities. The design of the pump enables a low shear and pulsation-free pumping action. This feature is particularly important when dealing with shear-sensitive fluids, as it helps maintain the integrity and quality of the pumped medium. It ensures that delicate substances or products are not damaged or compromised during the pumping process.

- High Viscosity Capability: One of the key advantages of progressive cavity pumps is their ability to handle high-viscosity fluids efficiently. These pumps can effectively transfer fluids with viscosities ranging from moderate to extremely high, even surpassing 100,000 centipoise. The unique rotor-stator geometry allows for the smooth movement of viscous fluids through the pump, ensuring reliable and consistent performance across a wide range of viscosity levels.

- Solids Handling Ability: Progressive cavity pumps excel in handling fluids containing solids or particulate matter. The cavities formed between the rotor and stator accommodate the passage of solid particles without causing clogging or damage to the pump. This makes them suitable for applications such as wastewater treatment, where sludge or thickened biosolids need to be transferred. The robust construction and continuous flow capability of progressive cavity pumps ensure efficient transport of fluids with solids content.

- Self-Priming: Another notable feature of progressive cavity pumps is their self-priming capability. This means that they can evacuate air or gases from the pump’s suction line and create a vacuum, allowing for quick and hassle-free startup. The self-priming feature eliminates the need for additional priming equipment or manual interventions, making these pumps convenient and user-friendly.

- Reversible Flow: Progressive cavity pumps offer the advantage of reversible flow. By simply changing the direction of rotation, the pump can reverse the flow direction, enabling efficient bi-directional pumping. This feature is beneficial in applications where periodic reversal of flow is required or in systems that require flexibility in fluid transfer.

Send Your Enquiry :