[wpseo_breadcrumb]

What is the Progressive Cavity Pump Parts?

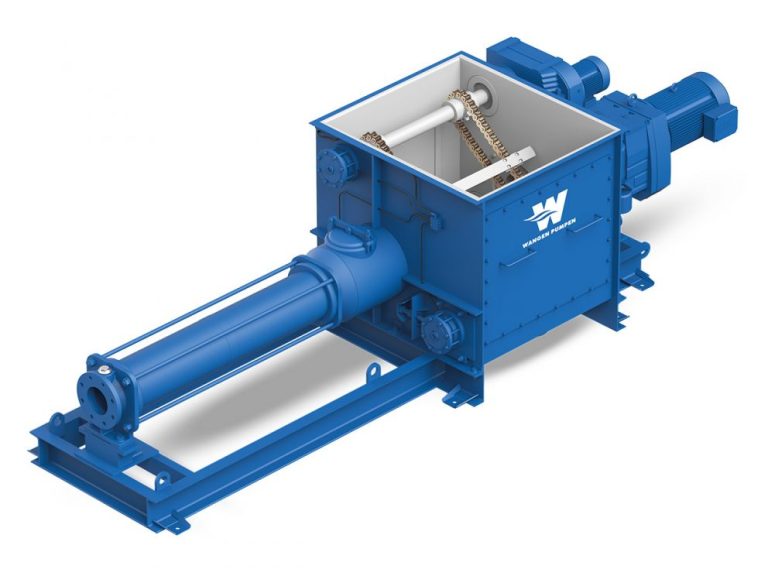

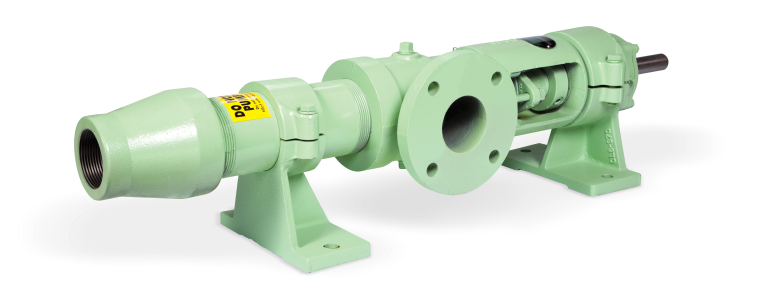

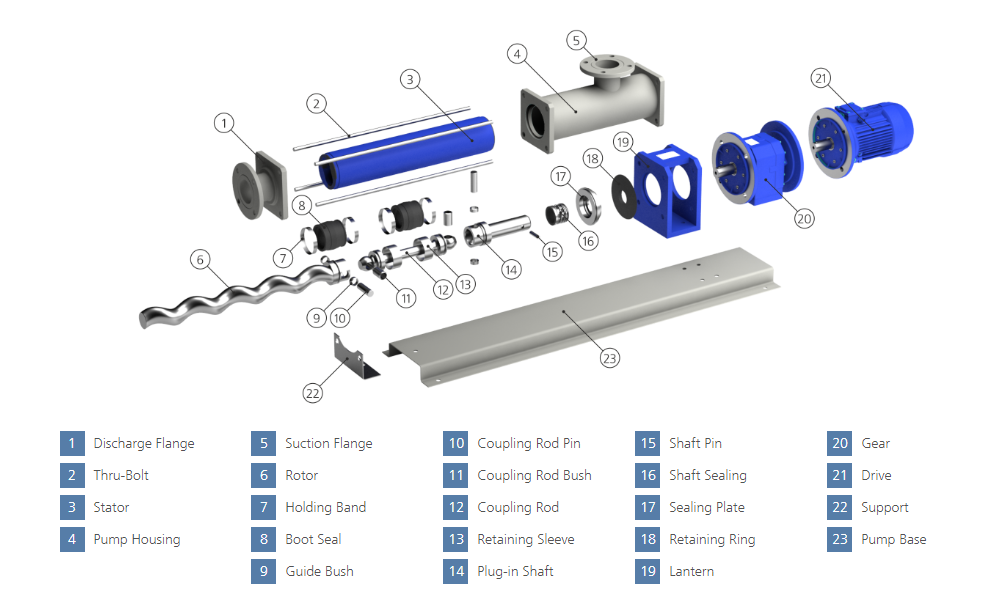

Progressive Cavity Pump Parts are essential components that make up progressive cavity pumps. They are designed for handling fluids with varying viscosities and consistencies, making them widely used in industries such as oil and gas, wastewater treatment, and food processing. These parts are known for their robust construction, precision engineering, versatility, and ability to handle shear-sensitive materials. They ensure efficient fluid transfer and reliable pump performance.

The Description of Progressive Cavity Pump Parts

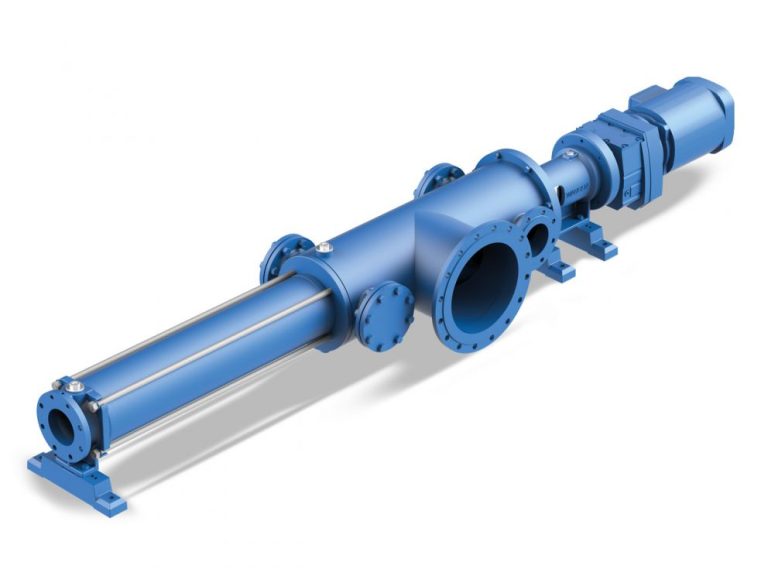

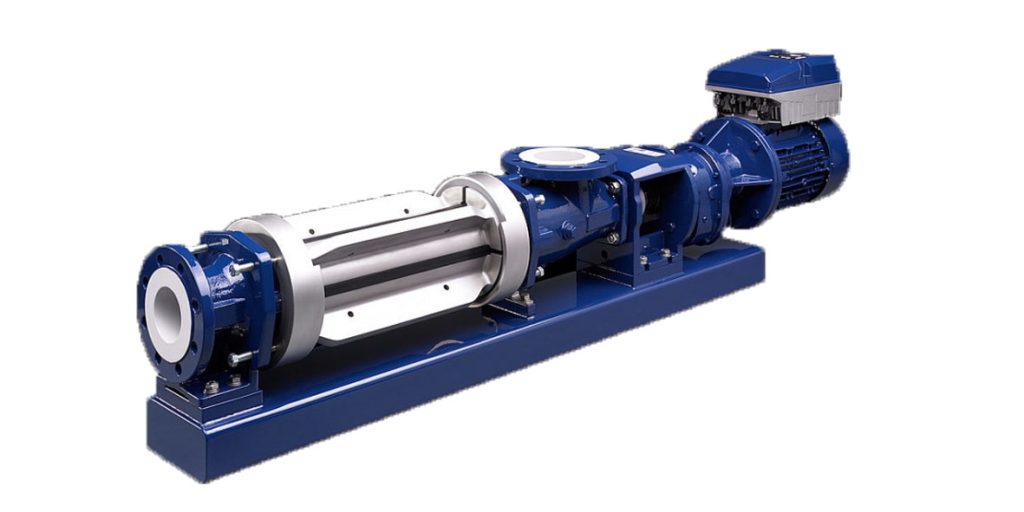

Progressive Cavity Pump Parts refer to the components that make up a progressive cavity pump, which is a type of positive displacement pump. These parts work in harmony to ensure the efficient transfer of fluids with varying viscosities and consistencies. Progressive cavity pumps are known for their ability to handle shear-sensitive and abrasive materials, making them widely used in various industries.

The Application of Progressive Cavity Pump Parts

Progressive Cavity Pump Parts find extensive applications across different sectors. They are commonly used in oil and gas, wastewater treatment, food processing, chemical, and mining industries. These parts play a crucial role in processes such as transferring viscous fluids, dosing chemicals, handling abrasive slurries, and pumping various media with high precision.

The Application of Progressive Cavity Pump Parts

- Robust Construction: Progressive Cavity Pump Parts are designed with durability in mind. They are typically made from high-quality materials such as stainless steel, hardened alloys, and elastomers, ensuring long-lasting performance even in demanding environments.

- Precision Engineering: These parts are manufactured with high precision to ensure optimal pump performance. The geometrical accuracy of the rotor and stator, critical components of a progressive cavity pump, allows for precise fluid displacement and consistent flow rates.

- Versatility: Progressive Cavity Pump Parts are versatile and can handle a wide range of fluid viscosities, from low to extremely high. They can effectively pump fluids with solids content, making them suitable for applications involving slurries and abrasive materials.

- Low Shear Operation: The unique design of progressive cavity pumps ensures gentle handling of shear-sensitive fluids. The progressive cavity pump parts work together to minimize turbulence and shear forces, making them ideal for transferring delicate and sensitive substances without degradation.

- Easy Maintenance: The modular design of progressive cavity pump parts allows for easy maintenance and replacement. Components such as rotors, stators, couplings, and seals can be readily accessed, reducing downtime and ensuring efficient pump operation.

The Conclusion of Progressive Cavity Pump Parts

Progressive Cavity Pump Parts play a vital role in the operation of progressive cavity pumps. Their robust construction, precision engineering, versatility, low shear operation, and easy maintenance make them indispensable in various industries. These parts enable efficient fluid transfer, reliable performance, and extended service life for progressive cavity pumps in diverse applications.

People Also Ask

Send Your Enquiry :