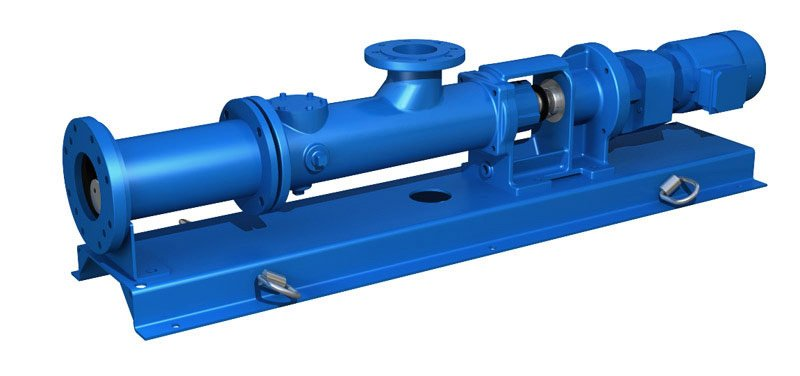

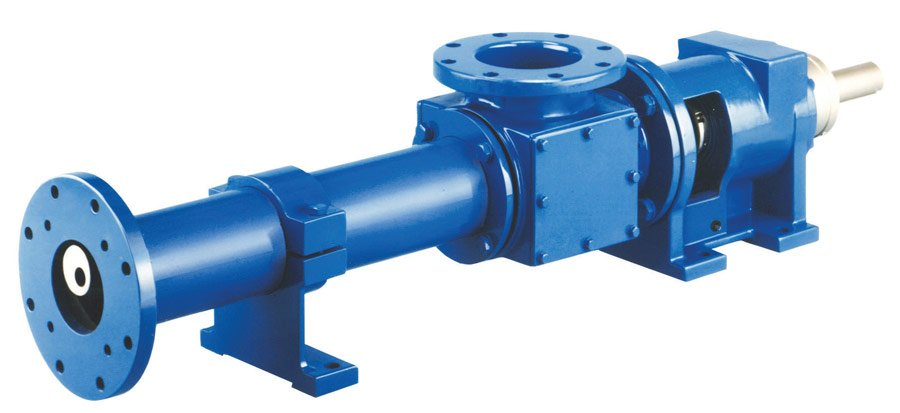

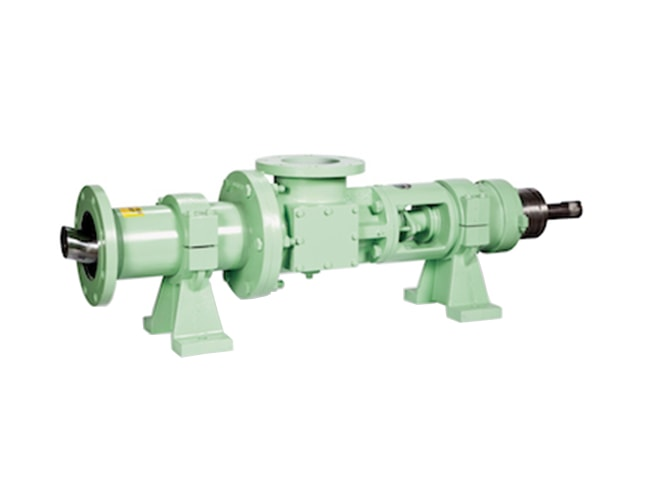

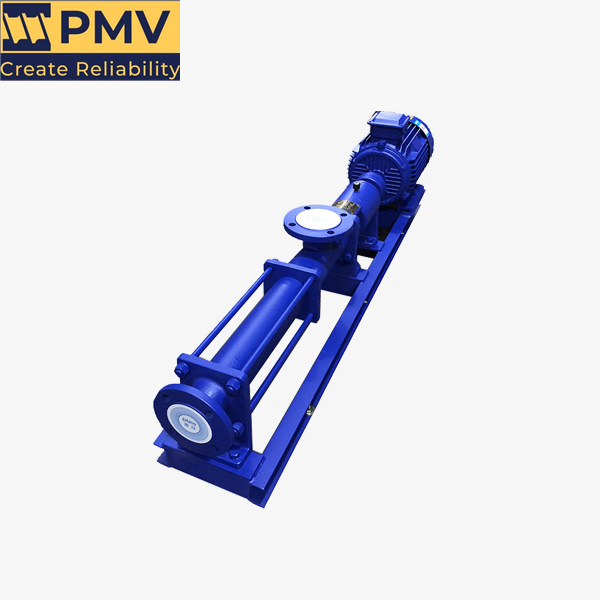

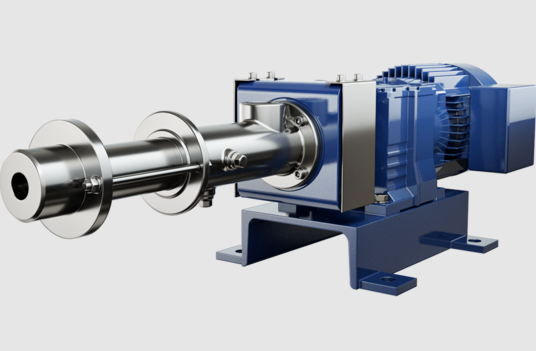

100 gpm progressive cavity pump

Working Principle The core working principle of the screw pump is to use the rotational motion of the screw to transport fluid. Its structure usually consists of one or more screws and a fixed pump housing. As the screw rotates, the fluid is gradually pushed between the screw and the pump housing, thereby achieving continuous…