The Description of Moyno Progressive Cavity Pumps

Moyno progressive cavity pumps are renowned for their exceptional performance and reliability. These pumps are specifically designed to operate as both screw pumps and progressive cavity pumps, offering versatility in fluid handling applications. With their unique design and construction, Moyno pumps provide efficient and precise fluid transfer, ensuring consistent flow rates and minimal pulsation. Whether you require gentle handling of shear-sensitive fluids or high-pressure pumping, Moyno progressive cavity pumps deliver superior performance and durability.

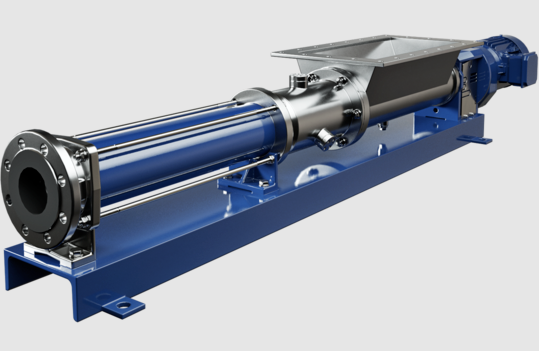

Mag Drive Pumps

The patented sealless magnetic drive design provides zero leakage for the most critical applications.

Mag Drive series are the first progressing cavity wobble stator pumps to offer magnetic drives. The proprietary, magnetic coupling design performs well in hazardous applications and is effective with difficult-to-seal fluids. This ensures operator safety and protects the environment from contamination.

The Features of Moyno Progressive Cavity Pumps

- Patented, sealless technology provides zero leakage, preserving expensive fluids, eliminating hazardous work place conditions and protecting the environment

- No mechanical seals are used, eliminating costly repairs

- Pulsation-free, low shear pumping action maintains product integrity

- No vapor locking when handling gaseous, volatile liquids

- Four models from which to choose for application versatility

- Various motor options available

- Materials of construction include PVC housings

- Stator materials include FPM with optional Nitrile and EPDM; Titanium rotors are standard

- Skid mounted, turnkey systems are available for one-stop, hassle-free shopping, saving time and money

The Applications of Moyno Progressive Cavity Pumps

- Sodium Hypochlorite

- Ammonia

- Hydrogen Peroxide

- Ferric Chloride

- Aluminum Chloride

- Ammonium Chloride

- Calcium Chloride

- Nickel Chloride

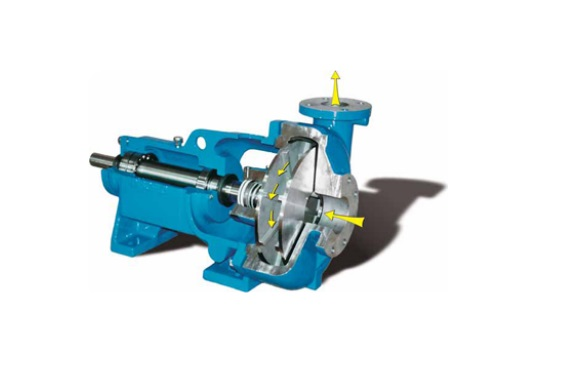

Compact C Pumps

Sealed pin joint design for a variety of applications.

Compact C Pump delivers reliable performance to the maximum duty requirements of your application in a compact package. Features include suction lift capability up to 28 feet, positive displacement for process control, and variable speed for accurate dosing.

Features

- Available in cast iron or stainless steel, with a choice of rotor and stator materials

- High pressure / long haul pumping, eliminating the need for a series of pumps when pumping over long distances or with high head requirements

- Available in standard geometry or extended pitch

- Gentle pumping action minimizes shear and crush damage

- Inspection cover available for applications where rag content is a problem

- The pump can be supplied with a square inlet and conveyor to assist viscous slurries into the pumping element

- Low running speeds – ideal for abrasive applications

Typical Applications

- Domestic and industrial effluents

- Sludge

- Milk curds, sauces, fruit juices

- Industrial chemicals

- Detergents

- Coating clays

- Gypsum and silicate

- Paper stocks

- Agriculture slurries

- Hydrated lime slurry

- Starch slurries

Send Your Enquiry :