Rotors for eccentric screw pumps

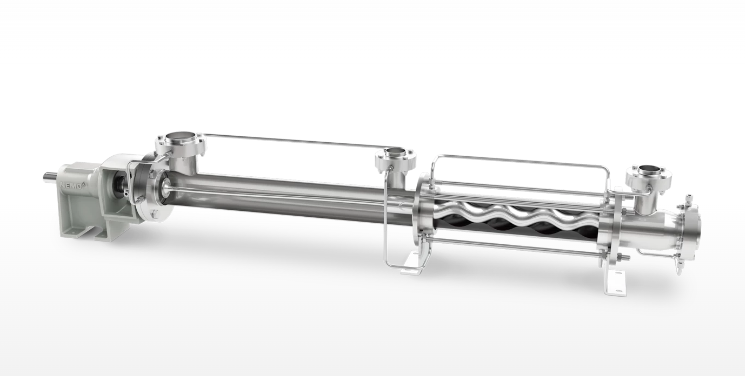

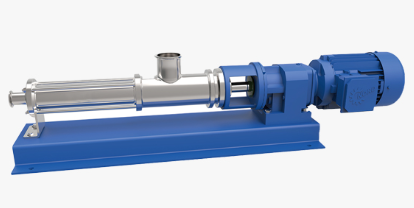

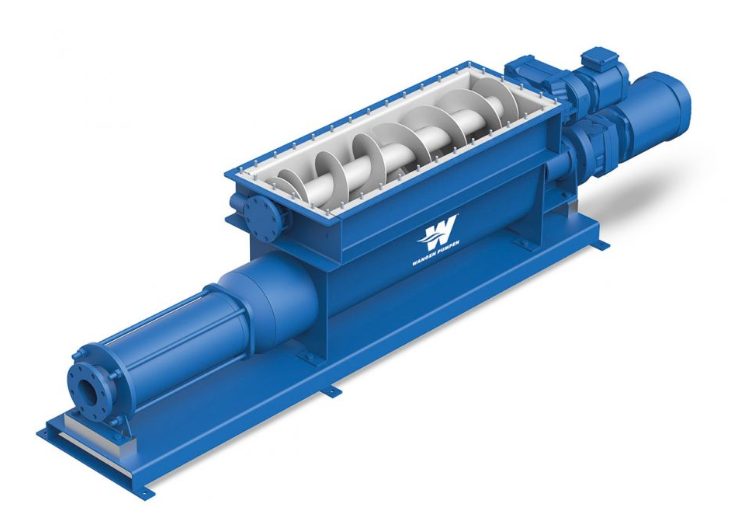

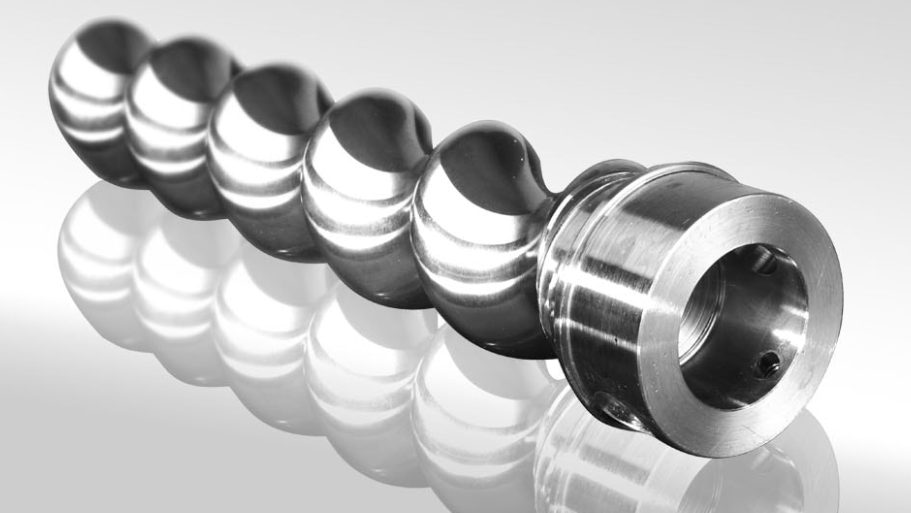

Eccentric screw pumps belong to the positive displacement pump family and are used where the technical tasks exceed the possibilities of pumps of conventional design. In the field of conveying technology, they are used for pumping abrasive, highly viscous and corrosive media. This has contributed to a significant expansion of the range of available conveying systems. Eccentric screw pumps consist of a rotating component, the rotor, and the stationary stator located around it. The rotor rotates eccentrically, as its axis of rotation does not correspond to the axis of symmetry of the stator. The construction of both components form chambers through which the respective medium is conveyed by rotation in the pump via the suction to the discharge side. Rotors consist mainly of steel and have a special spiral geometry as the rotating centre in the stator.

PMV Rotor Production

We manufacture single‑, double- and multi-start rotors for all pumping tasks – adapted to the respective media and requirements

In addition to our standard sizes, we also produce larger components up to a length of 8 metres for you. For rotors, we offer extensive coating techniques such as hard chrome plating and carbide coatings (e.g. tungsten carbide, chrome carbide) in order to guarantee maximum service life and minimize wear even with the most difficult pumping media in ever new areas of application.

New developments for the conveying technology, the creation of prototypes as well as all processing steps of the later series production can be carried out completely independently of external suppliers in our own company. Thus we offer the greatest possible security, also for your innovations!

The diverse fields of application of our rotors

Artemis rotors are often used in pumps at elevated temperatures. In order to ensure that the conveying system runs efficiently and smoothly, we adjust the rotor dimensions according to the expansion that occurs. As a specialist in components for conveyor technology, our rotors are used in the food industry, the chemical industry, the construction industry and in the extraction of crude oil, among others.

Our quality assurance

To ensure our high quality standards, we use the latest 3D coordinate measuring technology.

In our development and production processes, we pay attention to the perfect coordination of stator and rotor geometries to ensure optimum efficiency. We achieve this by using the latest 3D technology as well as simulations of the later operating behaviour of the rotor.

People Aso Ask

Fill up and submit the below inquiry form, or directly write us an email: info@pumpvv.com