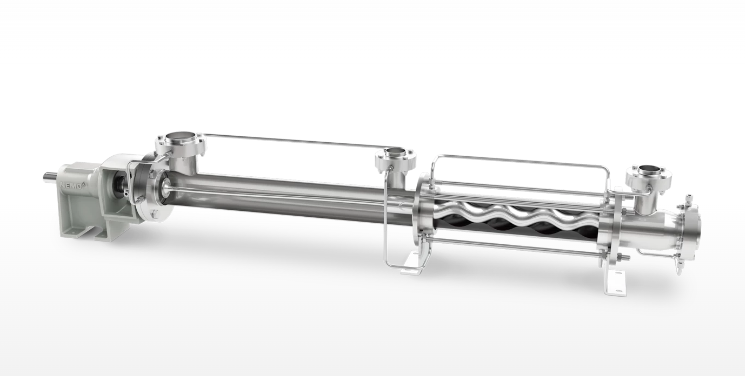

NEMO® SA Aseptic Pump

The NEMO® SA aseptic pump with bearing housing with a maintenance-free flexible rod is crevice free and used, because of its cleanability (CIP/SIP process), for aseptic and hygienic applications in the food, pharmaceutical, cosmetic and chemical/biochemical industries for continuous, pressure-stable, gentle and low-pulsation conveyance as well as dosing in proportion to speed.

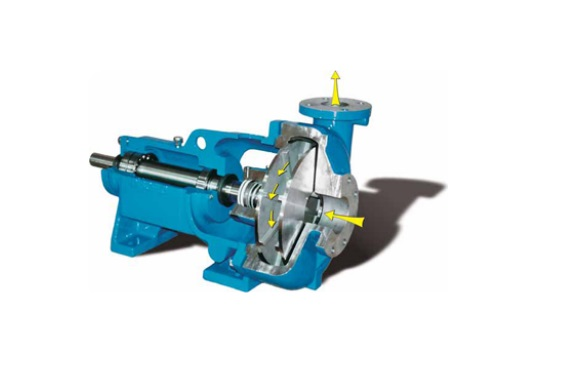

Description of NEMO SA Aseptic Pump

The NEMO SA Aseptic Pump is employed for aseptic and hygienic applications in the foodstuff, pharmaceutical,

cosmetic and chemical/biochemical industries in order to provide continuous, pressure-stable, gentle and lowpulsation conveyance and dosing in proportion to speed. To avoid contamination from the environment, all hermetic

areas can be sealed with steam or sterile condensate. The design with bearing block and free shaft ends enables the

universal employment of any drive type. Many different regulatory bodies have set specifications for a hygienically

correct configuration of components and machines, as well as for component cleanability. NEMO Aseptic Pumps

are designed, produced and inspected in accordance with the regulations of the EHEDG (European Hygienic

Equipment Design Group) and the QHD (Qualified Hygienic Design). The materials used are approved by the FDA

(Food and Drug Administration) and the BfR (German Federal Institute for Risk Assessment). In addition, NEMO

Aseptic Pumps meet the specifications.

Advantages of the NEMO SA Aseptic Pump:

- all hermetic areas are double-layered and sealed

- foodstuff-suitable shaft seals with compression-proof bolted seal casing enable reversal of the direction of rotation

- and thereby also of the direction of conveyance, up to the maximum pump pressure

- streamlined, crevice-free housing model with reduced diameter prevents sedimentation of the product

- all product-contacting surfaces are polished to prevent build-up of the medium and facilitate cleaning

Features of the NEMO SA Aseptic Pump

- perfectly crevice-free pumping space

- optimized flow through the pump

- continuous low-pulsation conveyance unaffected by fluctuations in pressure and viscosity

- conveyance volume in proportion to rotation speed with high dosing precision over a broad rotational-speed range

- high suction and pressure capability without valves

- reversible conveyance direction

- stator with funnel-shaped entrance for optimal filling of the conveying chamber

People Also Ask

Send Your Enquiry :