Progressive cavity pumps are widely used in various industries due to their ability to handle viscous fluids and provide a steady flow. One critical aspect of operating these pumps effectively is understanding the Net Positive Suction Head (NPSH). This article explores the importance of NPSH in the context of progressive cavity pumps, including its definition, significance, and best practices for ensuring optimal performance.

Understanding NPSH

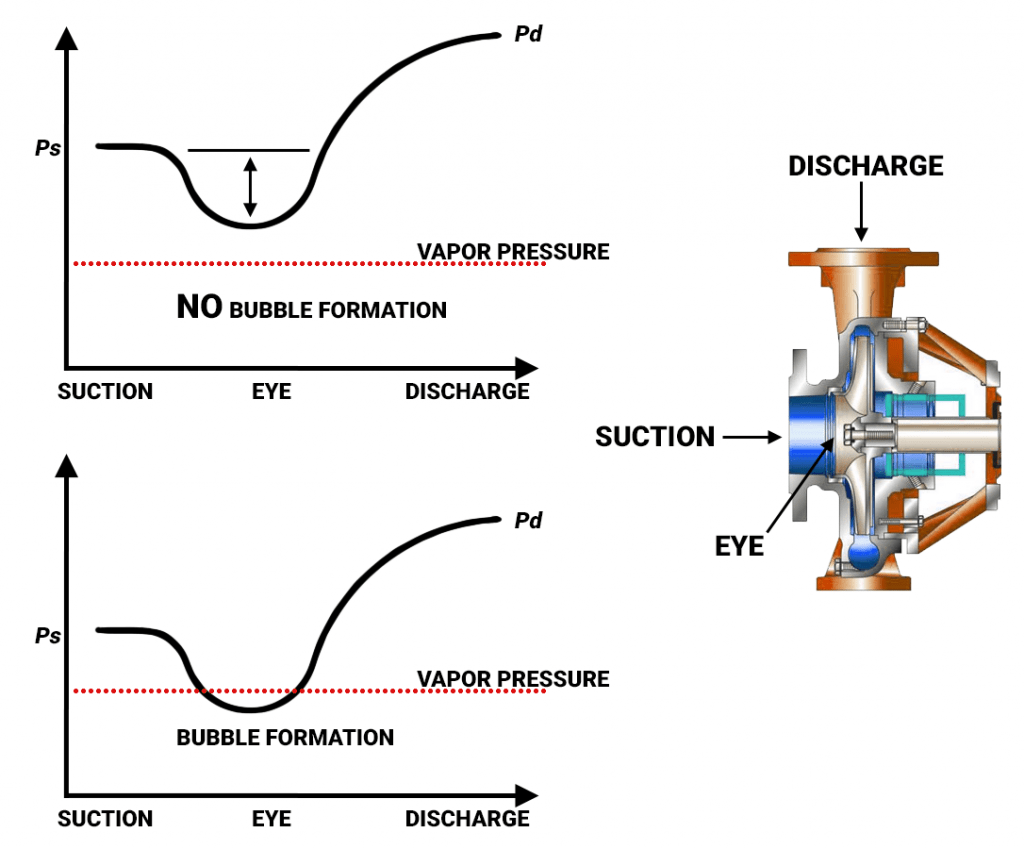

NPSH is a measure of the pressure available at the pump’s suction inlet, which is crucial for preventing cavitation. Cavitation occurs when the pressure in the pump falls below the vapor pressure of the fluid, leading to the formation of vapor bubbles. These bubbles can collapse violently, causing damage to the pump and reducing its efficiency.

Types of NPSH

There are two types of NPSH to consider:

- NPSH Available (NPSHA): This represents the actual pressure available at the suction side of the pump. It depends on the system design, elevation, and fluid properties.

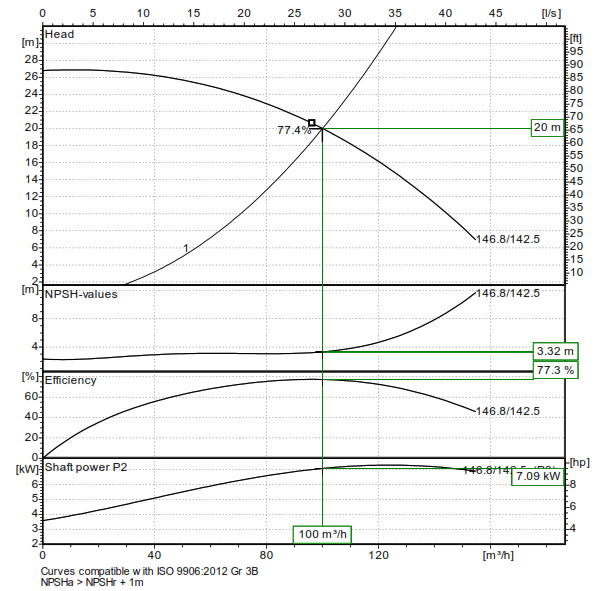

- NPSH Required (NPSHR): This is the minimum pressure needed at the pump inlet to avoid cavitation, determined by the pump manufacturer. Each progressive cavity pump has a specific NPSHR value based on its design and operating conditions.

Importance of NPSH in Progressive Cavity Pumps

Understanding and managing NPSH is essential for several reasons:

- Preventing Cavitation: Ensuring that NPSHA exceeds NPSHR is vital for preventing cavitation, which can lead to significant damage over time.

- Maintaining Efficiency: Proper NPSH levels help maintain the pump’s efficiency. Cavitation not only causes damage but also results in decreased flow rates and increased energy consumption.

- Enhancing Longevity: By managing NPSH effectively, operators can extend the lifespan of the pump and reduce maintenance costs.

- Improving Reliability: Consistent operation within the recommended NPSH limits contributes to the overall reliability of the pumping system.

Best Practices for Managing NPSH

To optimize NPSH for progressive cavity pumps, consider the following best practices:

- Evaluate System Design: Assess the entire pumping system, including the layout, pipe diameters, and fluid characteristics, to ensure adequate NPSHA.

- Monitor Fluid Levels: Maintain appropriate fluid levels in the supply tank to avoid fluctuations that can affect NPSHA.

- Use Appropriate Piping: Implement piping that minimizes bends and restrictions to reduce pressure losses.

- Select Suitable Pumps: Choose progressive cavity pumps with a suitable NPSHR for your specific application to ensure compatibility with your operating conditions.

- Regular Maintenance: Conduct routine inspections and maintenance to identify and address any issues that may impact NPSH, such as blockages or leaks.

Conclusion

In conclusion, understanding NPSH is crucial for the effective operation of progressive cavity pumps. By ensuring that NPSHA exceeds NPSHR, operators can prevent cavitation, maintain efficiency, and enhance the longevity and reliability of their pumping systems. Implementing best practices for managing NPSH will lead to improved performance and reduced operational costs, benefiting various industrial applications.

People also ask

Fill up and submit the below inquiry form, or directly write us an email: info@pumpvv.com