Introduction

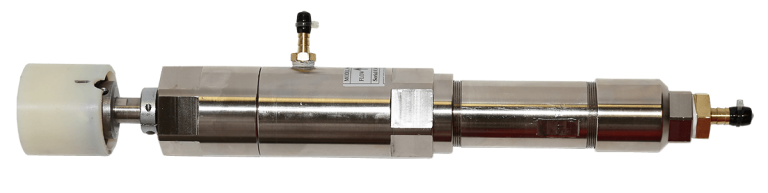

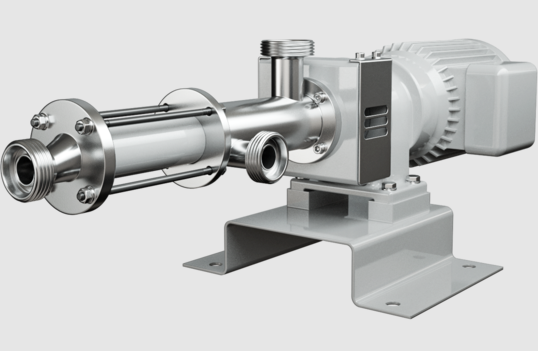

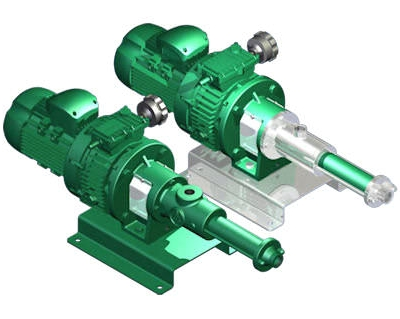

The Nova Rotors Progressive Cavity Pump is a specialized pumping solution designed for a variety of demanding applications. Known for its efficiency and reliability, this pump is widely used in industries ranging from wastewater treatment to food processing. In this article, we will explore the key features, advantages, and applications of this innovative pump.

Key Features

- Unique Design

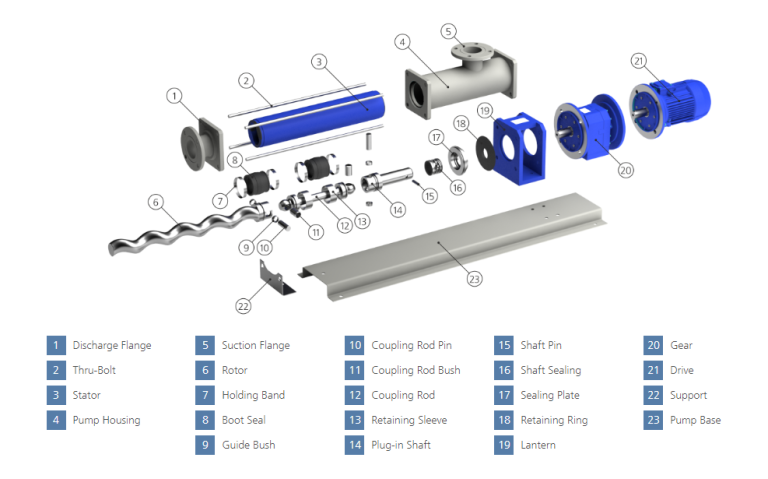

The progressive cavity pump features a helical rotor that moves fluid through a stator. This design allows for a consistent and smooth flow, minimizing turbulence and shear stress on the fluid. - Versatility

These pumps can handle a wide range of fluids, including viscous, corrosive, and abrasive substances. Their adaptability makes them suitable for various industries. - Low Maintenance

Nova Rotors pumps are designed for durability, requiring minimal maintenance over their operational life. This reliability reduces downtime and operating costs. - Self-Priming Capability

The self-priming nature of these pumps ensures they can start pumping without the need for manual priming, enhancing operational efficiency.

Advantages

- Consistent Flow Rate

One of the standout features of progressive cavity pumps is their ability to maintain a steady flow rate regardless of changes in pressure. This characteristic is crucial for processes that require precision. - Energy Efficiency

The design of the Nova Rotors pump allows for reduced energy consumption compared to traditional pumping systems. This efficiency can lead to significant cost savings over time. - Minimal Pulsation

The smooth operation of the pump results in minimal pulsation, which is beneficial for sensitive applications that cannot tolerate fluctuations in flow. - Wide Range of Applications

From handling slurries in mining to transferring food products in the culinary industry, the versatility of these pumps makes them an invaluable asset in many sectors.

Applications

- Wastewater Treatment

These pumps are extensively used in the treatment of wastewater, capable of handling solids and thick sludge effectively. - Food and Beverage Industry

In food processing, the pumps are ideal for transferring viscous products like sauces, syrups, and dairy products without compromising quality. - Chemical Processing

The ability to handle aggressive chemicals makes the Nova Rotors pump a preferred choice in the chemical industry, ensuring safe and efficient transportation of hazardous materials. - Oil and Gas Industry

The pumps are equally efficient in oil extraction and transportation, managing high-viscosity fluids with ease.

Conclusion

The Nova Rotors Progressive Cavity Pump stands out as a reliable and efficient solution for various industrial applications. Its unique design, energy efficiency, and versatility make it an excellent choice for businesses seeking to enhance their pumping operations. With its wide range of applications and minimal maintenance requirements, this pump represents an investment in quality and performance for any industry.

People also ask

Send Your Enquiry :