The Description of PCM Pump

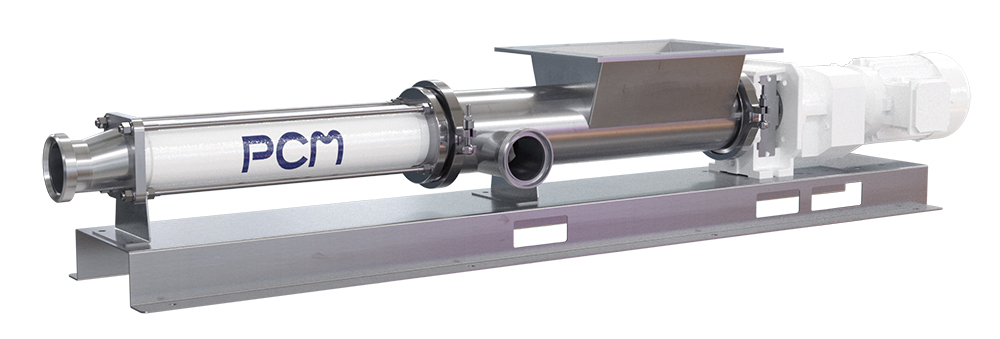

PCM Pump is a leading manufacturer of progressive cavity pumps, offering reliable and efficient solutions for various industries. Their pumps are known for their robust construction, precise engineering, and exceptional performance. PCM Pump’s progressive cavity pumps are designed to handle a wide range of fluids, including viscous, abrasive, and shear-sensitive media. With a focus on innovation and quality, PCM Pump delivers reliable pumping solutions that meet the diverse needs of its customers.

The Application of PCM pump

PCM pumps are widely used in various applications, including oil and gas, chemical processing, food and beverage, and wastewater treatment. They are known for their versatility and reliability, making them suitable for handling a wide range of fluids, from abrasive and corrosive liquids to viscous and shear-sensitive materials. PCM pump excel in applications that require precise dosing, gentle product handling, and efficient transfer of fluids.

The Features of PCM Pump

PCM pumps offer several key features that make them highly desirable in various industries. These features include:

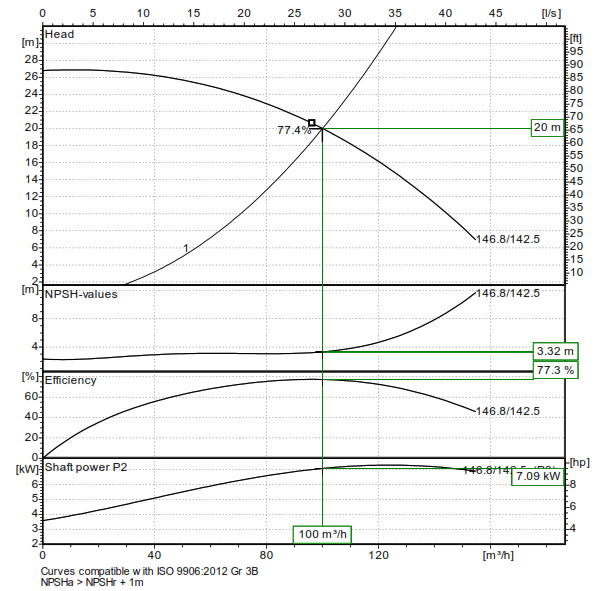

- Positive Displacement: PCM pumps utilize a positive displacement mechanism, ensuring accurate and consistent flow rates regardless of changes in pressure or viscosity.

- Versatility: These pumps can handle a wide range of fluids, including abrasive, corrosive, viscous, and shear-sensitive liquids, making them suitable for diverse applications.

- Gentle Product Handling: PCM pumps have a gentle pumping action, minimizing product degradation and maintaining the integrity of sensitive materials.

- Reliability: With robust construction and high-quality materials, PCM pumps are designed for long-lasting performance, reducing downtime and maintenance costs.

- Efficiency: These pumps offer excellent efficiency, delivering optimal performance while minimizing energy consumption and operating costs.

Leading Progressive Cavity Pump Manufacturers: PCM, Netzsch, and Seepex

PCM Pump, Netzsch, and Seepex are prominent manufacturers of progressive cavity pumps. PCM Pump is known for its innovative designs and versatile applications, offering reliable and efficient pumping solutions. Netzsch is recognized for its high-quality pumps and extensive industry expertise. Seepex is renowned for its precision-engineered pumps that deliver accurate and consistent performance. Each company has its unique strengths, making them trusted choices for customers worldwide.

People Also Ask

Send Your Enquiry :