Introduction to Moyno Progressive Cavity Pumps

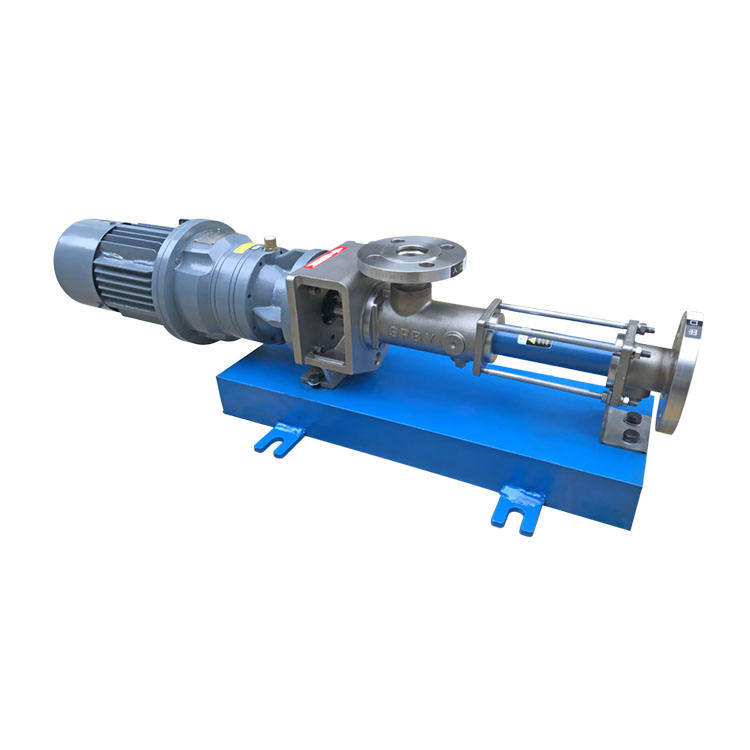

Moyno progressive cavity pumps are renowned for their versatility and efficiency in handling a wide range of fluids. These pumps are particularly effective in industries such as wastewater treatment, food processing, and chemical manufacturing. Their unique design allows for the smooth and consistent flow of viscous liquids, making them a popular choice for various applications.

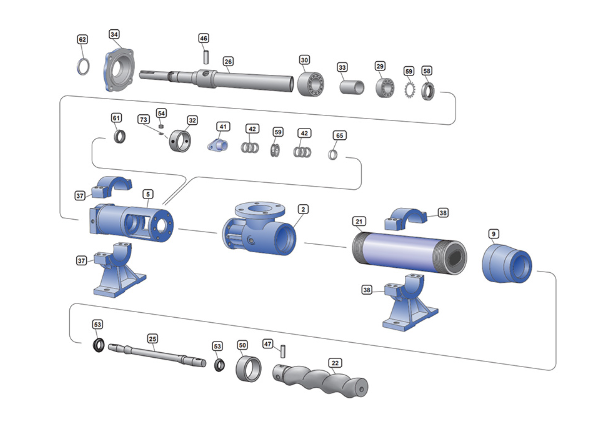

How Progressive Cavity Pumps Work

Progressive cavity pumps operate using a helical rotor that rotates within a stator. This design creates a series of cavities that move the fluid from the inlet to the outlet. The key features of this pump type include:

- Helical Rotor Design: The rotor’s shape ensures that fluid is transported in a continuous manner, minimizing turbulence and shear.

- Consistent Flow Rate: The pump provides a steady flow regardless of the pressure, making it ideal for applications requiring precision.

- Self-Priming Capability: Moyno pumps can handle slurries and fluids with gas entrainment without losing efficiency.

Applications of Moyno Progressive Cavity Pumps

Moyno pumps are utilized in a variety of industries due to their adaptability. Some common applications include:

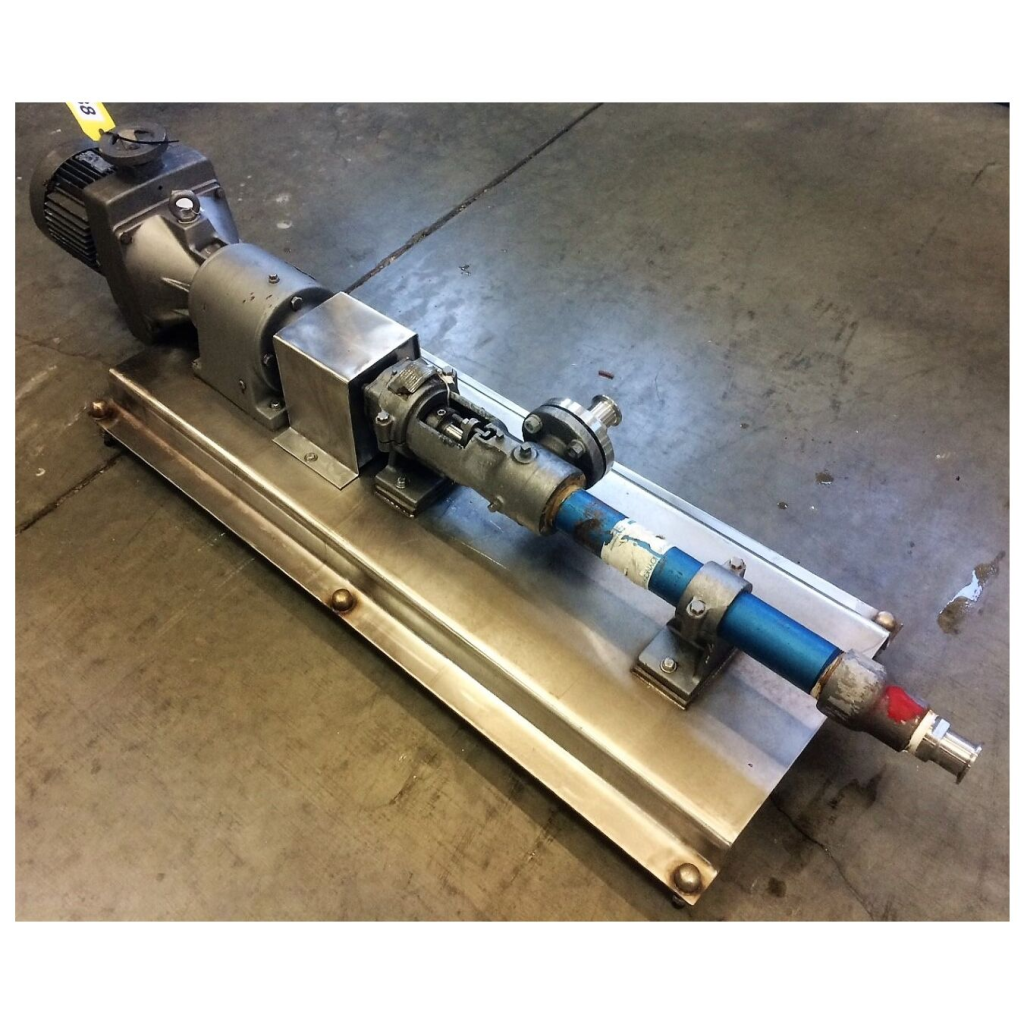

- Wastewater Treatment: Efficiently moving sludge and other viscous fluids.

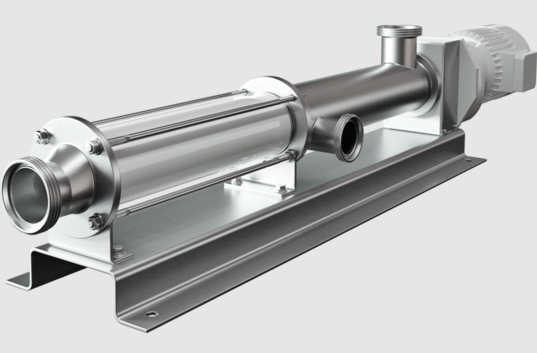

- Food Processing: Handling ingredients and products that require gentle pumping.

- Chemical Manufacturing: Transfer of corrosive and abrasive materials safely and reliably.

Advantages of Moyno Progressive Cavity Pumps

Moyno progressive cavity pumps offer several advantages that set them apart from other pump types:

- Versatility: They can handle a wide range of fluid types, from thin liquids to highly viscous substances.

- Low Maintenance: Their simple design results in fewer moving parts, reducing wear and tear over time.

- Energy Efficiency: The design allows for lower energy consumption compared to centrifugal pumps, especially in viscous applications.

Conclusion

In conclusion, Moyno progressive cavity pumps are an essential component in various industrial applications due to their reliability and efficiency in transporting a wide range of fluids. Their unique design and operational capabilities make them suitable for challenging environments, ensuring that industries can operate smoothly and effectively. As technology continues to advance, the role of these pumps in modern applications will likely expand, further solidifying their importance in fluid management.

People also ask

Send Your Enquiry :