Netzsch NM045by01l06b

What is a progressive cavity pump?

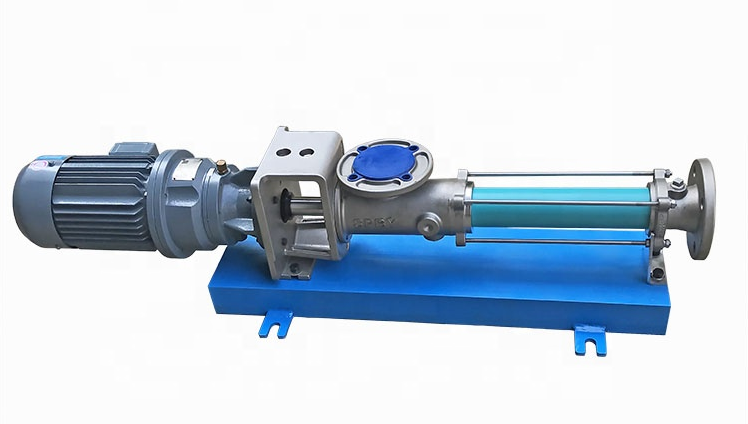

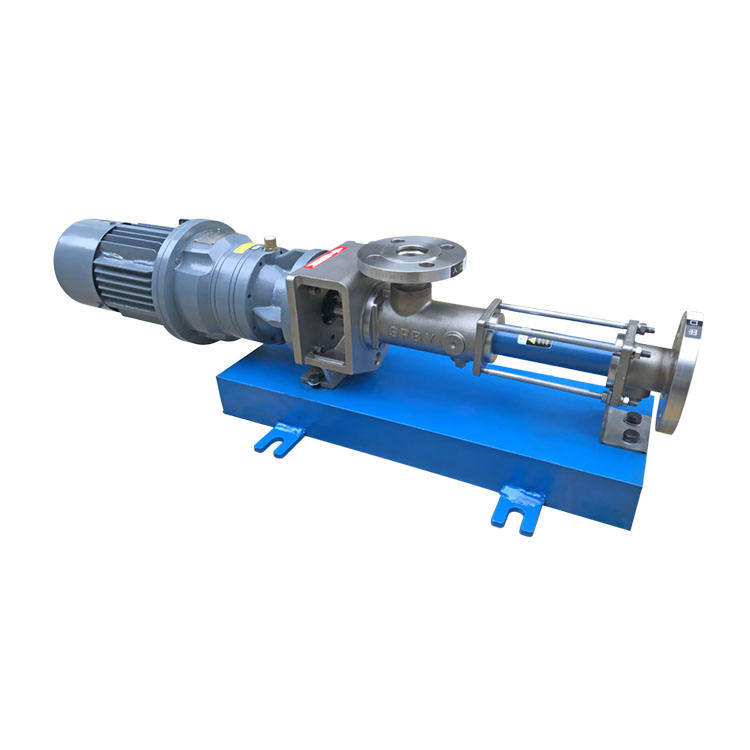

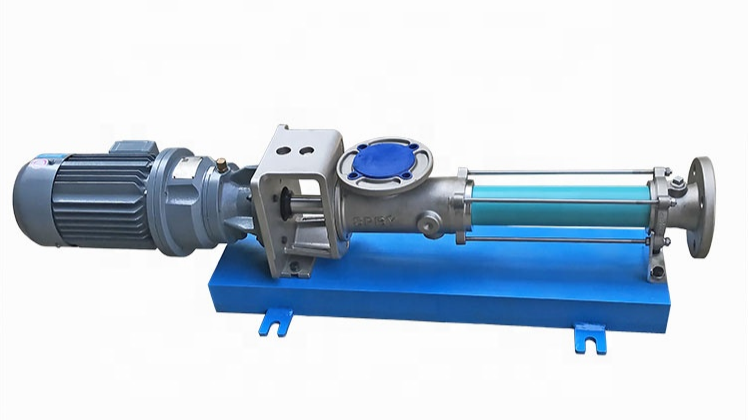

Name : Progressive Cavity Pump

(Single Screw Pump)

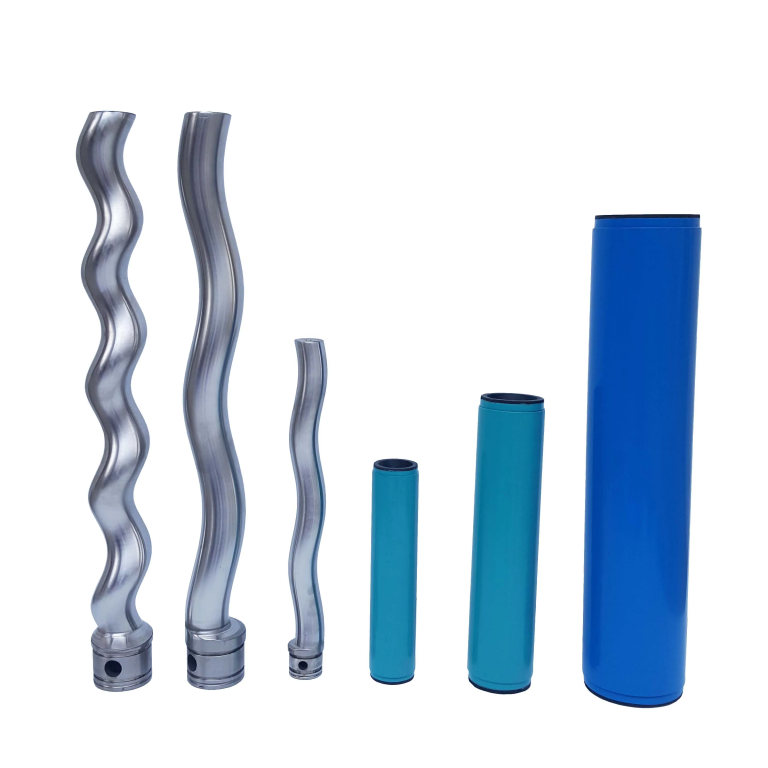

Material :Progressive cavity pump parts, including the screw and helical rotor, are usually made of corrosion-resistant materials like 304SS or 316L stainless steel.

Model : See photo model-01 / model-02(equal to NETZSCH series)

Applicable medium : For any medium with or without solid content for different viscosity.

Application : Environmental engineering, Food & Beverage, Paper industry, oil gas and petrochemicals, and Additional markets.

The Description of NM045by01l06b

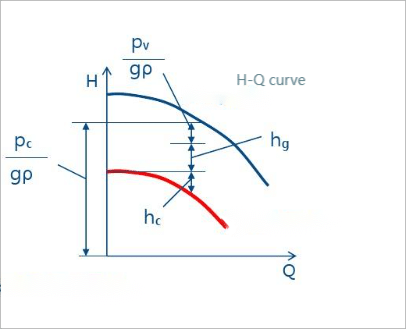

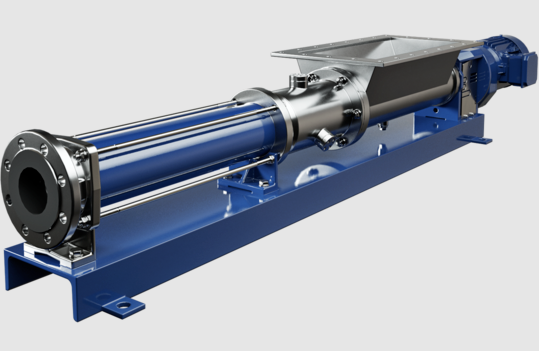

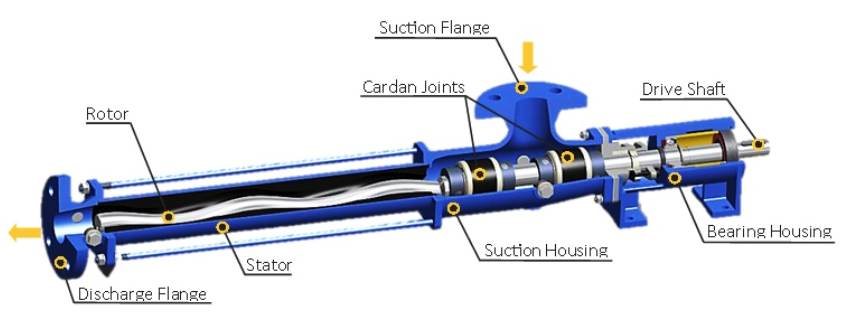

A netzsch pumps, also known as a helical rotor pump, consists of several progressive cavity pump parts such as an inlet, outlet, screw, helical rotor, pump head, motor, guiding bearing, and couplings. The screw and helical rotor form a pump chamber that moves along the length of the screw, allowing for fluid transportation and pressure adjustment. The guiding bearing supports the screw and reduces friction, while the couplings connect the motor and pump head to work together in coordination.

The Features of Netzsch NM045by01l06b Progressive Cavity Pump

Customized support : OEM

Brand Name : SHARPPUMP

Model Number : 045BY02S12B

Application : Biofuel Industry, Food and Beverage Industry, Machining, Marine, Metal and Equipment Manufacturers, Wastewater Transport and Flood Control, wastewater treatment, Water Distribution, Sewage

Horsepower : 4KW

Power Source : Electric

Pressure : 6-12KG, Low Pressure

Structure : SCREW PUMP

Outlet Size : DN80

Voltage : 380/400V

Usage : Water

Power : Electric

Material : 304SS

Warranty period : One Year

Netzsch NM045by01l06b Parts

[video_lightbox_youtube video_id=”JWkoODah0vY&rel=0″ width=”640″ height=”480″ alt=”Sludge Screw Pump” anchor=”https://pumpvv.com/wp-content/uploads/2023/03/pump-cover1.png”]

People Also Ask

Send Your Enquiry :