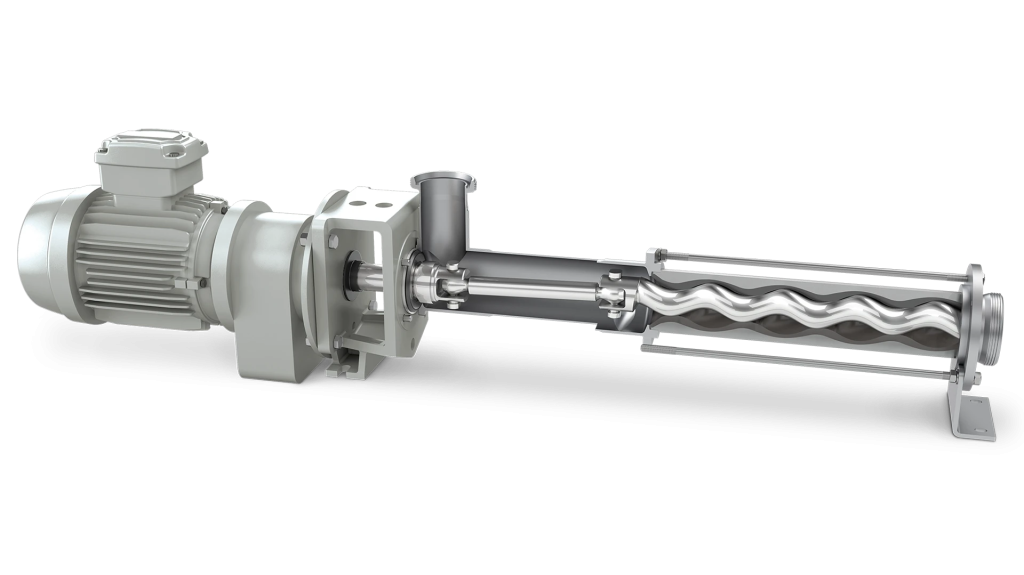

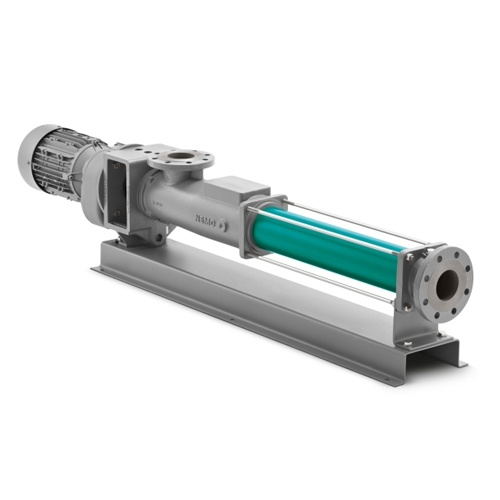

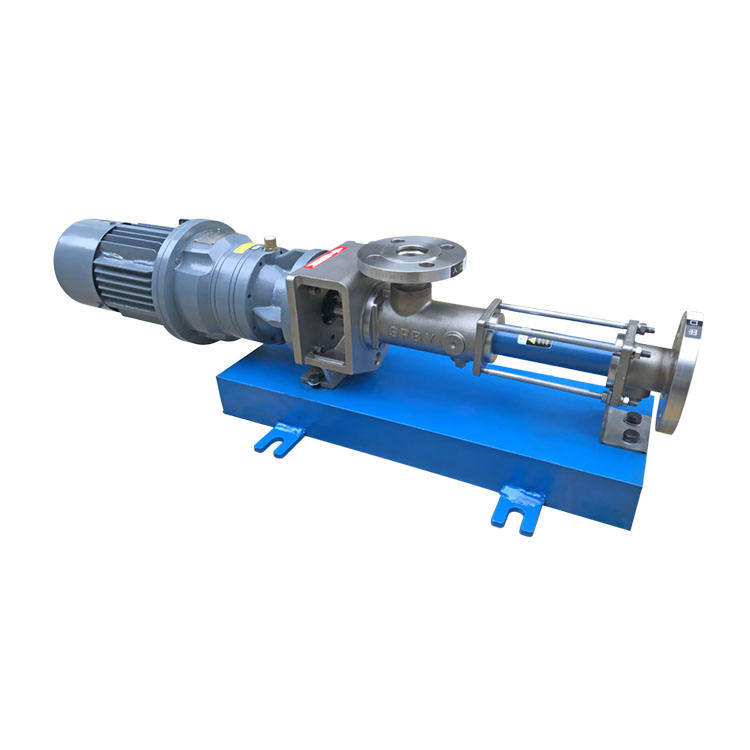

Netzsch NEMO® FSIP® Progressing Cavity Pumps

NEMO Progressing Cavity Pumps NEMO® Progressing Cavity Pumps have an extensive industrial application range for the continuous, pressure-stable, gentle and low-pulsation conveyance of almost any substance. Whether for sludge, chemical substances, adhesives, petroleum or yogurt, NEMO meets your requirements with the proper combination of eleven NETZSCH Pumps types, four rotor/stator geometries and variety of engineered…