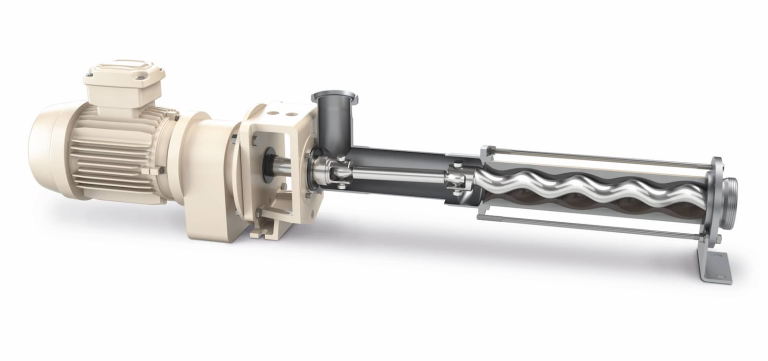

The Description of Netzsch Parts

Netzsch Parts are high-quality replacement components designed to fit Netzsch pumps and systems. These parts are manufactured with precision to ensure optimal performance and reliability.

The Application of Netzsch Parts

Netzsch Parts are suitable for various industrial applications such as chemical processing, oil and gas, pharmaceuticals, food and beverage, and mining. They are used in Netzsch pumps for smooth and efficient operation.

The Features of Netzsch Parts

1.Durability: Netzsch Parts are made from robust materials that can withstand demanding operating conditions, ensuring long-lasting performance.

2.Compatibility: These parts are specifically designed to seamlessly fit into Netzsch pumps, allowing for easy installation and a perfect match.

3.Versatility: Netzsch Parts are available in a wide range of sizes and configurations, catering to different pump models and applications.

4.Precision: Manufactured with utmost precision, Netzsch Parts meet stringent quality standards, delivering consistent performance and reliability.

5.Cost-effective: Investing in Netzsch Spare Parts helps prolong the life of pumps, minimizing downtime and reducing overall maintenance costs.

Netzsch Parts – Technology/Details

Material Selection: Netzsch Parts are carefully crafted using high-quality materials such as stainless steel, cast iron, and durable polymers, ensuring excellent resistance to corrosion, abrasion, and chemical attacks.

Precision Machining: These parts undergo precise machining processes to achieve tight tolerances and optimal fit, resulting in enhanced pump performance and reduced wear.

Advanced Engineering: Netzsch Parts are designed using advanced engineering techniques, incorporating innovative features to improve efficiency, reliability, and ease of maintenance.

Sealing Technology: Specialized sealing technologies are employed in Netzsch Parts to prevent leakage and ensure efficient fluid handling, even in challenging operating conditions.

Performance Testing: Every Netzsch Part undergoes rigorous performance testing to ensure superior performance, reliability, and compatibility with Netzsch pumps.

Customization Options: Netzsch Parts offer customization options to meet specific requirements, including custom designs, materials, and coatings, tailored to suit various industrial applications.

Quality Assurance: Netzsch Parts are manufactured under strict quality control measures, adhering to international standards, ensuring consistent quality, and customer satisfaction.

Send Your Enquiry :