[wpseo_breadcrumb]

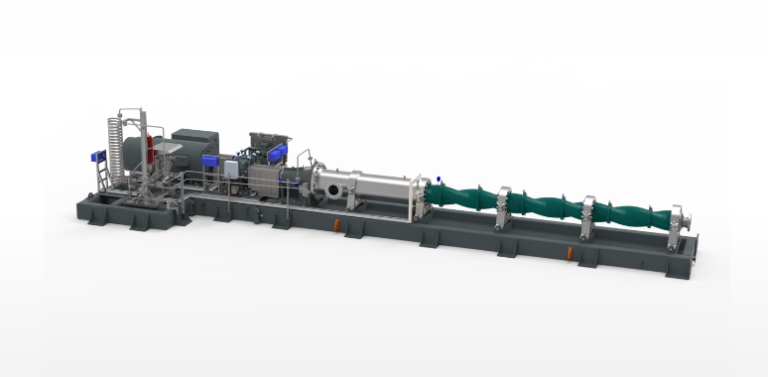

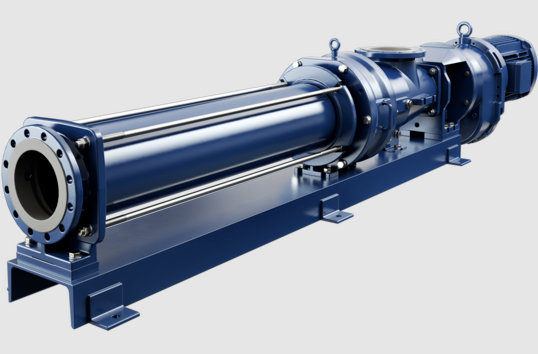

Innovative design of seepex BN35-12 Stator

The seepex BN35-12 stator is an efficient screw pump component designed to meet the needs of demanding industrial applications. Made of high-quality materials, the component has excellent wear and corrosion resistance, ensuring excellent performance and reliability when handling a variety of fluids. At the same time, its unique spiral structure optimizes fluid dynamics and greatly reduces energy loss, thereby significantly improving overall pump efficiency.

Performance advantages

The performance of the seepex BN35-12 stator can be summarized in a few keywords: efficient, durable, and flexible. First, its excellent efficiency can easily handle fluids of various viscosities and adapt to different industrial application scenarios. Secondly, its excellent wear and corrosion resistance greatly extends the service life of the equipment, which is essential for reducing maintenance frequency and downtime. In addition, the customization options provided by seepex enable companies to choose the most suitable components according to their needs, thus having greater flexibility in the fierce market competition.

Wide range of applications

Chemical industry

In the chemical industry, drastic changes in fluid properties are the norm. The seepex BN35-12 stator is able to effectively handle a variety of chemical media. Its design ensures safety and reliability when handling highly viscous and corrosive liquids, greatly improving production efficiency. Many chemical companies choose the BN35-12 stator to bring excellent benefits to their production processes.

Food and Beverage Industry

The food and beverage industry has extremely high requirements for hygiene and safety. The seepex BN35-12 stator meets food safety standards, and its material properties enable it to effectively prevent contamination when transporting liquid foods. In addition, its high efficiency and easy maintenance make this component more popular with food manufacturers.

Mining Industry

In the mining industry, handling viscous and highly corrosive slurries is a major challenge. With its excellent durability and anti-wear performance, the seepex BN35-12 stator can operate for a long time under harsh working conditions and meet the demanding needs of mining companies.

people also ask

Send Your Enquiry :