[wpseo_breadcrumb]

Introduction

Performance

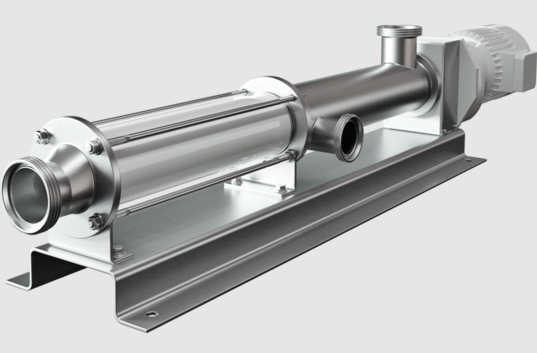

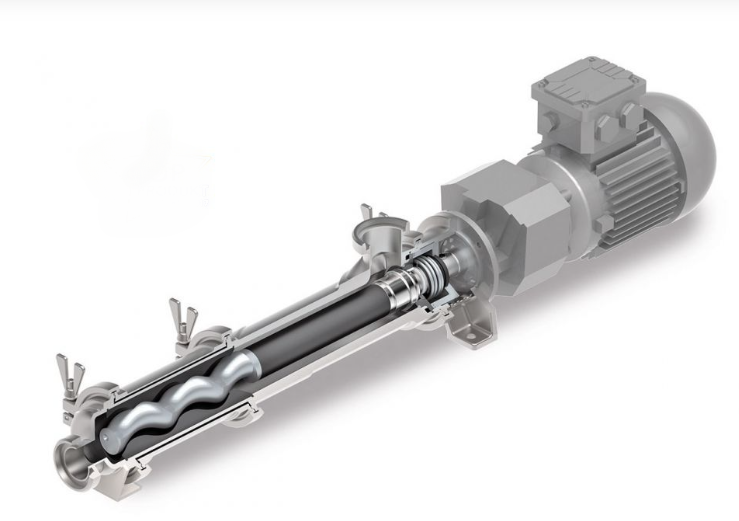

The seepex BN35-12 rotor can achieve gentle and uniform conveying, avoiding excessive shearing and damage to the medium. This not only ensures the stability of product quality, but also greatly improves the service life of the pump. Compared with traditional single-screw pumps, the BN35-12 rotor has significant advantages in conveying capacity and efficiency, and can meet the needs of high flow and high pressure in the fields of food, pharmaceuticals, and chemicals.

Maintenance

In addition to its outstanding performance characteristics, the seepex BN35-12 rotor is also excellent in terms of ease of use and maintainability. It adopts a modular design, and each component can be quickly disassembled and replaced, which greatly shortens the maintenance time. At the same time, the pump body and rotor are made of high-quality wear-resistant materials and have a longer service life. All of these bring users a good user experience.

Application areas

With these advantages, the seepex BN35-12 rotor is widely favored in many industries such as food, medicine, and chemicals. In the pharmaceutical industry, this pump is widely used in the production of raw materials, preparations, etc., and can stably and efficiently convey various viscous and easy-to-agglomerate raw material slurries. In the chemical industry, it is the preferred equipment for handling high-viscosity and high-pressure media, such as fatty acids and greases.

Custom upgrades

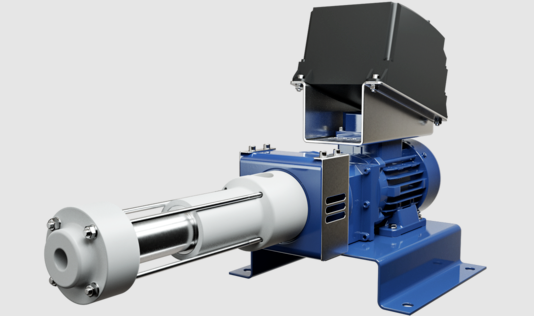

It is worth mentioning that seepex has also made a variety of customized upgrades to the BN35-12 rotor for different industries and applications. For example, in the food industry, it can use food-grade materials according to hygiene standards and be equipped with a CIP cleaning system to ensure product hygiene and safety. In the chemical industry, special corrosion-resistant materials can be selected according to the corrosiveness of the medium to increase the service life of the pump.

people also ask

Send Your Enquiry :