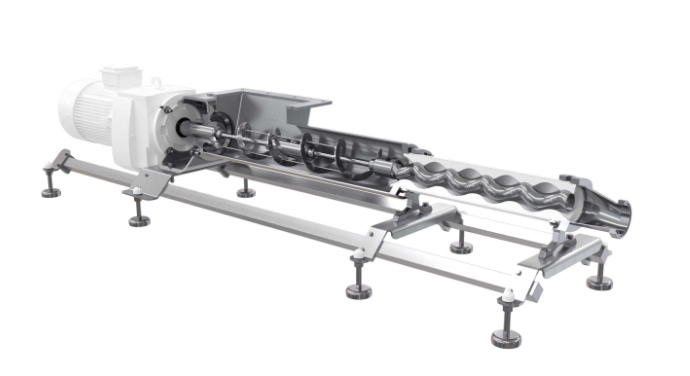

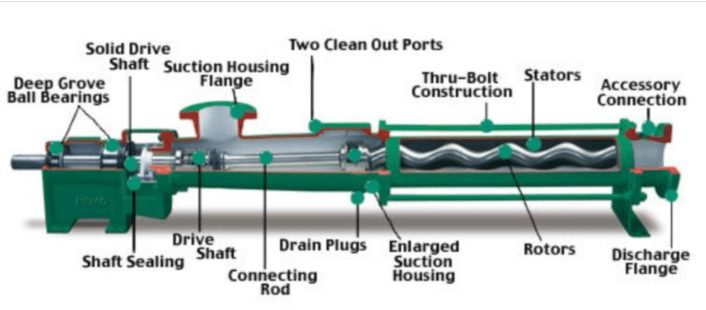

NEMO® SY Progressive Cavity Pump

NETZSCH NEMO® SY progressing cavity pumps are used in demanding applications for continuous, pressure-stable, gentle and low-pulsation conveyance as well as dosing in proportion to speed in nearly every branch of industry worldwide. The progressing cavity pump convinces through an extremely broad spectrum of applications.

Description of NEMO® SY Progressive Cavity Pump

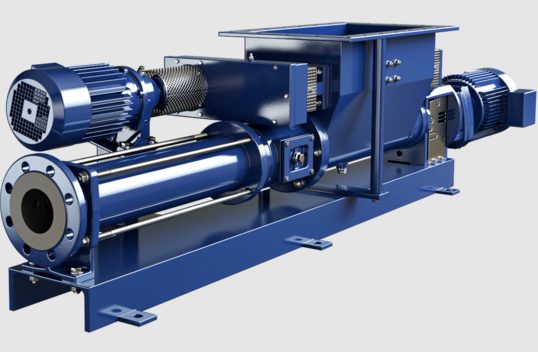

NEMO® SY progressing cavity pumps are used in demanding applications for continuous, pressure-stable, gentle and low-pulsation conveyance as well as dosing in proportion to speed in nearly every branch of industry worldwide. The progressing pumps convinces through an extremely broad spectrum of applications. Preferably, thin to viscous, solids-containing, shear-sensitive, lubricating and non-lubricating, thixotropic and dilatant as well as abrasive or adhesive media are conveyed. The nemo pump is ideally suited for high-pressure applications. Four different rotor/stator geometries are available, enabling the pump to be customized perfectly to your application case. Furthermore in bearing block design and with a free shaft end, the pump can be driven by all types of drives, such as servo motors, diesel engines or hydraulic drives.

Versatile Pumping Solution for Demanding Applications: NEMO® SY Progressive Cavity Pump

The NETZSCH Progressive Cavity Pump is an ideal solution for applications involving thick, viscous, or shear-sensitive liquids such as adhesives, slurries, and petrochemicals. Its gentle pumping action ensures minimal product degradation and provides a consistent flow rate. Additionally, the pump’s customizable design allows it to be tailored to meet specific application requirements, making it suitable for a wide range of industries including chemical processing, food production, and wastewater treatment.

Features of NEMO® SY Progressive Cavity Pump

- Variable, modular construction system

- Various rotor/stator geometries and a wide range of materials

- The right joint for every application

- Mechanical seal as standard, other seals optional

- Delivery pressure up to 72 bar

- Gentle product conveyance

- Pump connections according to national and international standards, as well as in special design

- Easy serviceability

People Also Ask

Send Your Enquiry :