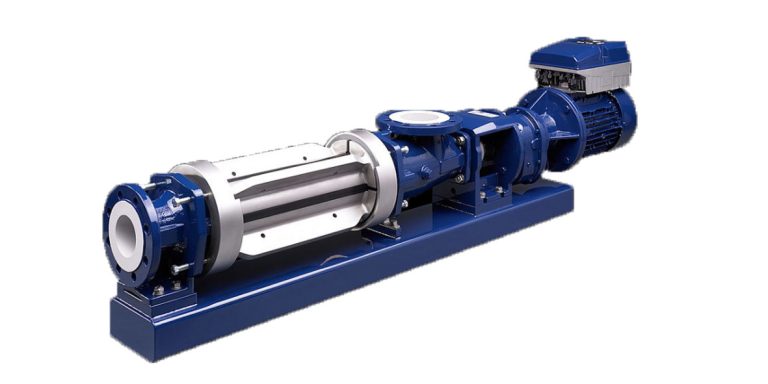

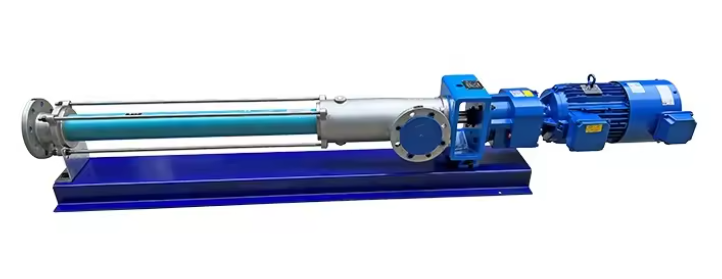

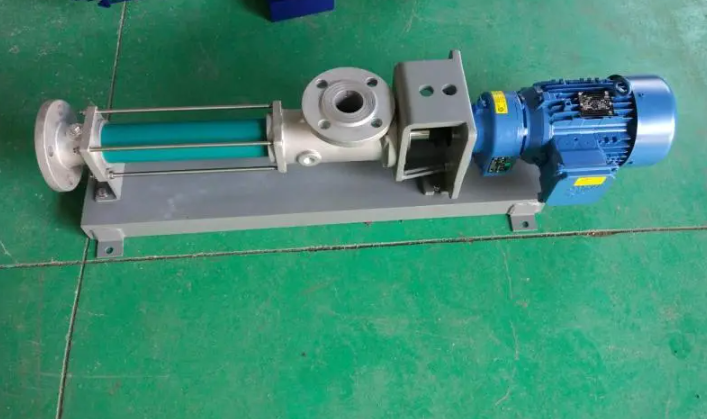

Working principle of NM090BY01L06B screw pump

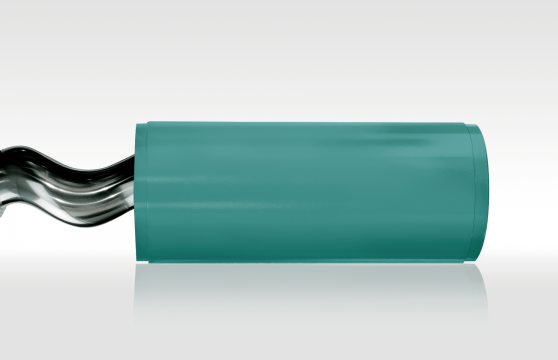

Based on the rotation of the screw and the movement of the helix. When the main screw rotates, it draws the liquid from the inlet into the pump body, compresses the liquid, and pushes it to the outlet along the helix. As the screw rotates, the liquid is compressed, resulting in high pressure at the pump outlet. Since the bulge of the screw pushes the liquid along the helix, a continuous closed space is formed inside the rotor, and the liquid is continuously compressed and discharged in this space.

Advantages of NM090BY01L06B

Transmitting difficult-to-transmit liquids

Can transmit high-viscosity liquids, liquids containing solids or bubbles, high-concentration mud, and other liquids that cannot be smoothly transmitted by previous pump products.

Ensure that the liquid does not deteriorate during the transmission process

Can transmit highly perishable substances such as whipped cream, polymer coagulants, and cake materials.

Pulsation-free quantitative transmission

There is no pulsation during discharge, so quantitative transmission can be achieved according to the set value. And the discharge volume can be freely controlled by adjusting the rotation speed.

Control the rotation speed and change the discharge volume instantly

Since a fixed amount of the transmission material will be discharged every time the rotor rotates once, the discharge volume can be changed instantly by changing the motor rotation speed.

Energy-saving and silent technology is used to reduce noise and odor

Since no other driving sounds are emitted when the transmission object moves in the pipe except the sound of the motor running, it can ensure that there is basically no noise and no odor.

Wide range of applications, not affected by capacity, pressure, and liquid quality

The material has characteristics such as wear resistance and drug resistance. Therefore, it can transmit drugs such as sulfuric acid and sodium hypochlorite.

| Drive mode | Electric | Inlet and outlet diameter | 60 |

| Discharge pressure | 0.6MPa | Suction distance | 5m |

| Speed | 198r/min | Lift | 60m |

| Power | 18.5KW | Working temperature | 40℃ |

| Flow rate | 20.0m3/h | Application scope | Transportation |

People also ask

Send Your Enquiry :