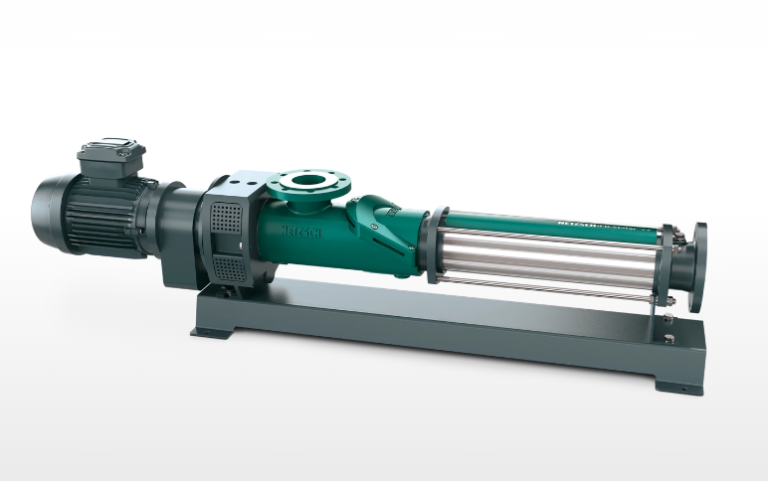

NM125BY01L06B Parameters

| Brand | NETZSCH | Shaft Power | 11 |

| Model | NM125BY01L06B | Suction Diameter | 200mm |

| Speed | 280(rpm) | Discharge Diameter | 200mm |

| Weight | 200kg | Efficiency | 98% |

| Power | 30kW | Pump Shaft Position | Horizontal |

| Drive | Electric | Material | Stainless Steel |

| Lift | 60m |

NM125BY01L06B Applications

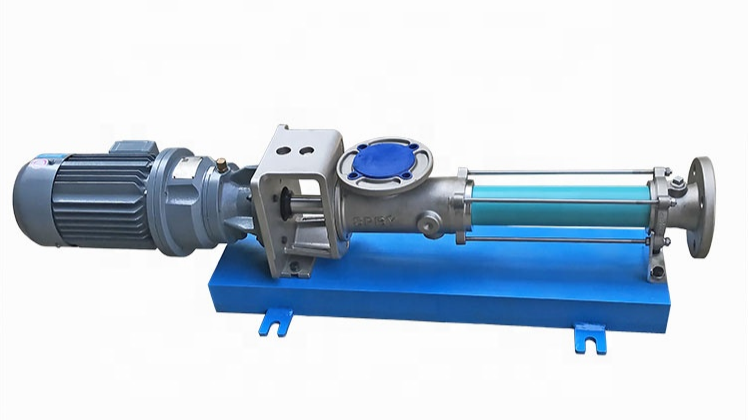

Environmental protection: transportation of industrial sewage, domestic sewage, muddy water containing solid particles and short fibers. Especially suitable for oil-water separators, plate and frame filter presses and other equipment.

Petroleum industry: transportation of crude oil. In recent years, it has been particularly successful in pumping out a mixture of crude oil and water from a depth of a thousand meters underground, and a mixture of coalfield gas and water in coalfields, thereby greatly reducing the cost of mechanical oil production and coalfield gas production. When the oil field reaches the later stage, a screw pump is used to inject polymers into the formation to increase the oil field recovery rate.

Medicine and daily chemicals: transportation of various viscous slurries, emulsions, various ointments and cosmetics, etc.

Construction industry: spraying and transportation of cement mortar, lime slurry, coatings and their pastes.

Brewing industry: various fermented viscous liquids, concentrated wine tanks, grain product residues, various sauces, pulps and mucus containing solid matter, etc.

Chemical industry: various suspensions, greases, various colloid slurries, various adhesives.

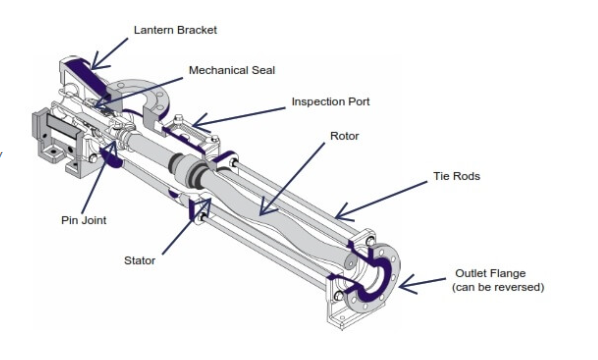

Netzsch NM125BY01L06B has the following main advantages:

High efficiency: The efficient single screw design can achieve high conveying efficiency, thereby reducing energy consumption and operating costs.

Easy maintenance: The modular design makes repair and maintenance relatively simple.

Wide applicability: It can convey various fluids with high viscosity, particles and solid content, and is suitable for chemical, food, pharmaceutical and other industries.

Low noise: The gentle operation mode makes the pump work with low noise.

Corrosion resistance: Key components such as the pump body and rotor are made of high-quality stainless steel with excellent corrosion resistance.

Strong customizability: It can be customized according to customer needs to meet the requirements of different application scenarios.

Long service life: The precise manufacturing process and high-quality materials ensure the long service life of the pump.

In general, Netzsch NM125BY01L06B is an industrial single screw pump with excellent performance and wide application range, and has good application prospects in various fluid conveying applications.

People also ask

Send Your Enquiry :