[wpseo_breadcrumb]

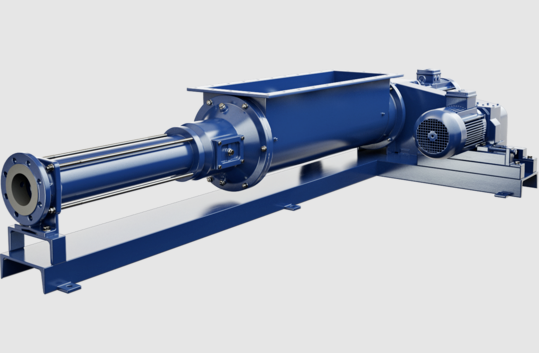

NEMO® FSIP® Progressing Cavity Pumps for Efficient Servicing

Save up to 66 percent of servicing time, the NEMO® progressing cavity pumps in FSIP® design make it possible. They are available in three variants and can generally be used in all industrial areas where very different media have to be conveyed with low pulsation, as well as unaffected by fluctuations in pressure and viscosity, or dosing tasks.

The description of NEMO® FSIP® Progressing Cavity Pumps

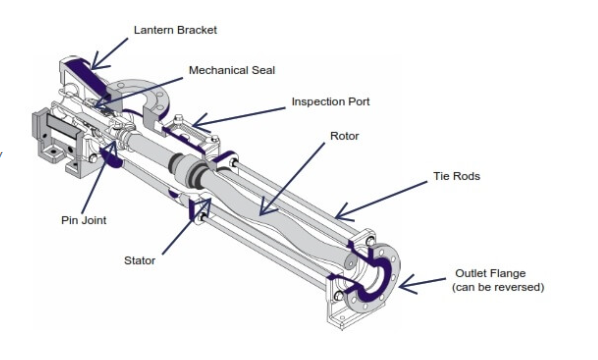

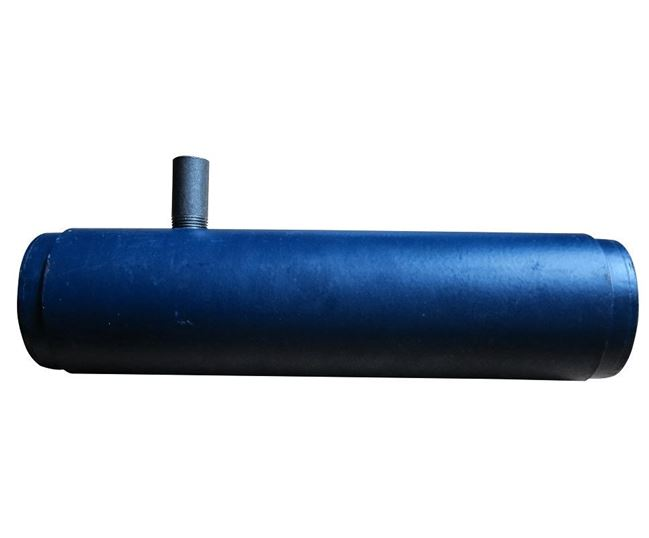

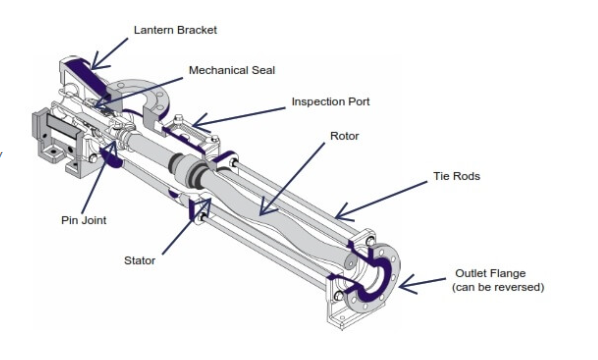

The NETZSCH FSIP® concept of the NEMO® progressing cavity pump is especially interesting where pumps are installed in wear intensive applications requiring more service and maintenance work. Up to 66 percent of working time can be saved when changing the stator. The FSIP® pump is designed in a way that the housing itself functions as support and orientation guideline. The special design enables that each part automatically fits into its destination. Positioning is done automatically without further adjustments. Therefore the change of all wear parts takes less than half of the time required so far. In block construction with a flanged drive, this NEMO® pump is particularly compact and economical. The pump also differentiates itself by means of low investment and operating costs. In FSIP® design the pump can help to safe even more maintenance costs and costs caused by downtimes. The three variants are the FSIP.ready, the FSIP.advanced and the FSIP.pro. The FSIP.ready is a basic BY Pump inclusive revised housing design with inspection cover, with standard drive train and standard seal arrangement. The FSIP.advanced is a BY pump with new housing design and large inspection cover, split coupling rod. Rotor and stator can be serviced in place. The FSIP.pro is also based on the BY pump with new housing design and large inspection cover, split coupling rod, cartridge unit and single acting mechanical seal for “Full Service in Place”. Two rotor/stator geometries are available to cover a broad spectrum of products and applications.

The application of NEMO® FSIP® Progressing Cavity Pumps

The NETZSCH NEMO® FSIP progressive cavity pump is widely used in industries such as food and beverage, chemical, pharmaceutical, and oil and gas. Its modular design and hygienic construction make it an ideal choice for applications that require regular maintenance and cleaning. The pump’s advanced technologies, including its conveying screw and coupling rod design, ensure high efficiency and low pulsation, making it a reliable solution for various pumping applications.

The features of NEMO® FSIP® Progressing Cavity Pumps

The NETZSCH NEMO® FSIP Progressive Cavity Pump boasts a number of impressive features, such as a robust and reliable construction that is capable of handling even the toughest of applications. Its unique design also ensures low pulsation and shear forces, making it suitable for use with sensitive and delicate media. Additionally, the pump’s modular system allows for customization to meet specific application needs, while its high-performance stator technology ensures consistent performance over long periods of operation. Overall, the NETZSCH NEMO® FSIP Progressive Cavity Pump offers a range of benefits that make it an ideal choice for a variety of industries and applications.

People Also Ask

Send Your Enquiry :