Pump Screw-PMV Pump

People Also Ask

Single screw pumps are a type of positive displacement pump that utilize a single helical rotor to move fluids. They are widely used in various industries due to their ability to handle a wide range of fluids, including viscous and shear-sensitive materials.

People Also Ask

What is a screw pump? Screw pump is a part of the dry compressed gas transfer pump series. They are positive displacement pumps that use one or more screws to move fluid or water along the screw shaft. These screws interlock to pressurize the fluid and move it into the system. These screws engage each…

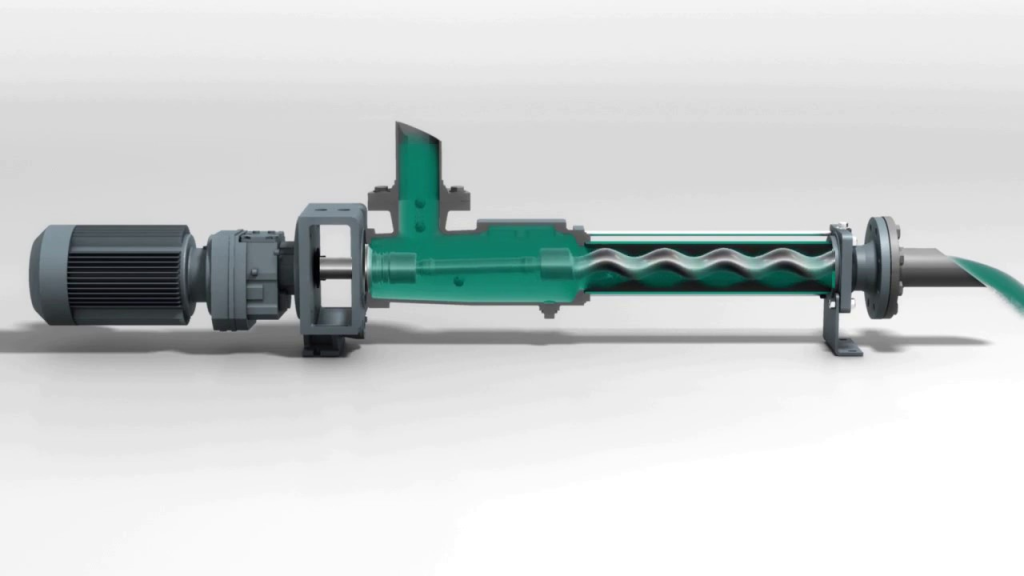

Introduction to Screw Pump Diagram. A screw pump diagram is a schematic representation of the working principle and components of a screw pump. Screw pumps are positive displacement pumps that use rotating screws to move fluids or slurries through a system. They are widely used in various industries due to their ability to handle high…

Hygienic Twin Screw Pump, More Commonly Known as Sanitary Twin Screw Pump. The hygienic twin screw pump is an advanced pumping solution designed for applications requiring high hygiene standards. It is generally know as a sanitary twin screw pump,and specifically developed to handle sensitive and viscous fluids in industries such as food and beverage, pharmaceuticals,…

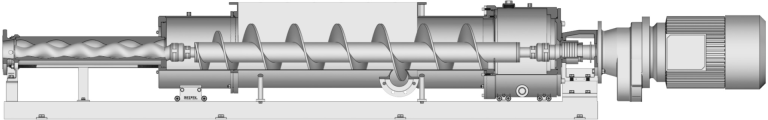

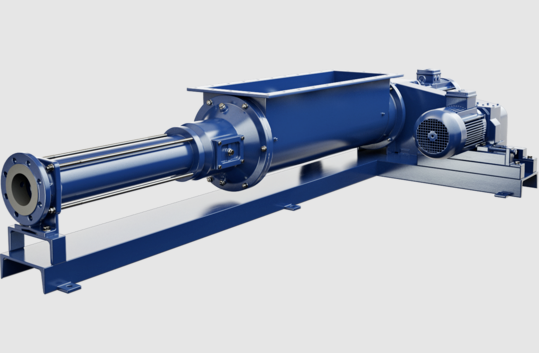

2000 HS Large Screw Pumps The 2000 HS System combines high pump efficiency with low discharge pressure to provide unmatched performance in high solids sludge cake transfer. Compared to hydraulically driven, piston ram type pumps and open conveyors, the 2000 HS System requires a much lower capital investment, lower operating costs and less maintenance. People…

SIMULTANEOUSLY FAST AND SLOW Always the right speed: Because the ribbon screw of the BTH hopper pump from SEEPEX has its own separate second drive system, it can be operated at a different speed from the rotating unit. Thanks to the large diameter and elongated pitch of the edge-to-edge ribbon screw, even media that tend…

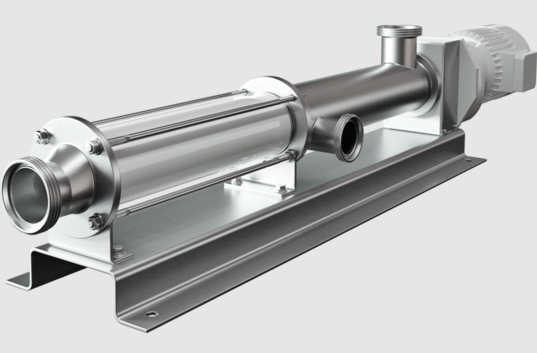

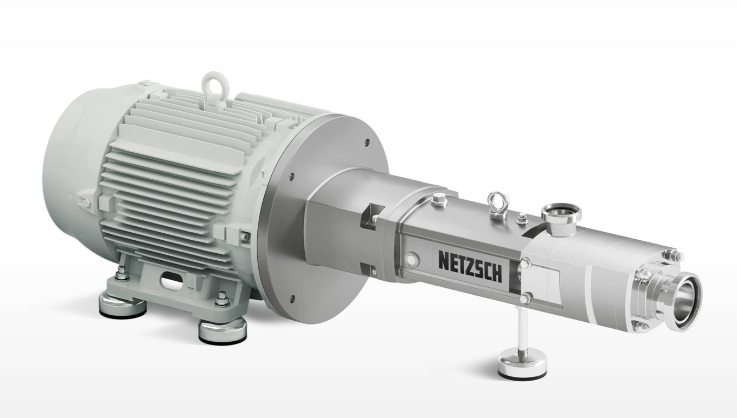

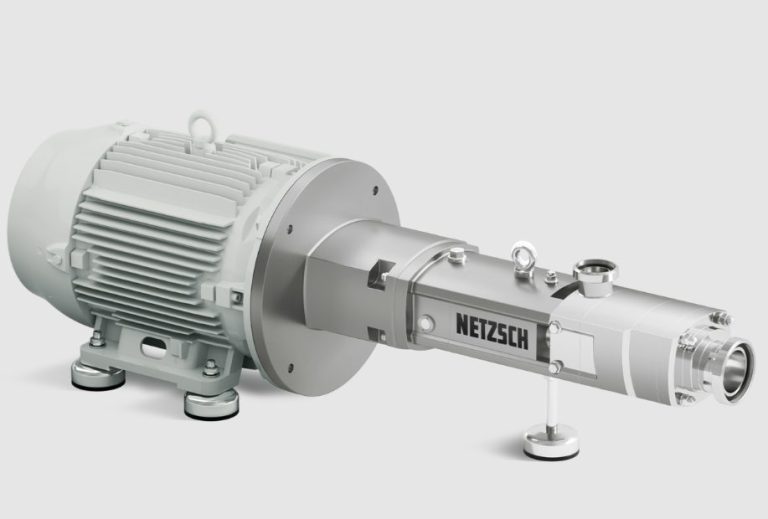

NETZSCH NOTOS® 2NSH Hygienic Twin Screw Pump in FSIP® Design The NOTOS® 2NSH hygienic twin screw pump in FSIP® (Full Service in Place) design impresses with gentle pumping, low pulsation, simple maintenance and ease of operation in the process. People Also Ask

NETZSCH NOTOS® 2NSH Screw Pump NETZSCH NOTOS is made of AISI 316L stainless steel and polished according to international standards, making iteasy to clean (CIP) and to sterilize (SIP). As there is no contact between the rotating parts, the pump speedcan be increased. Therefore cleaning can be carried out without the need for an auxiliary…

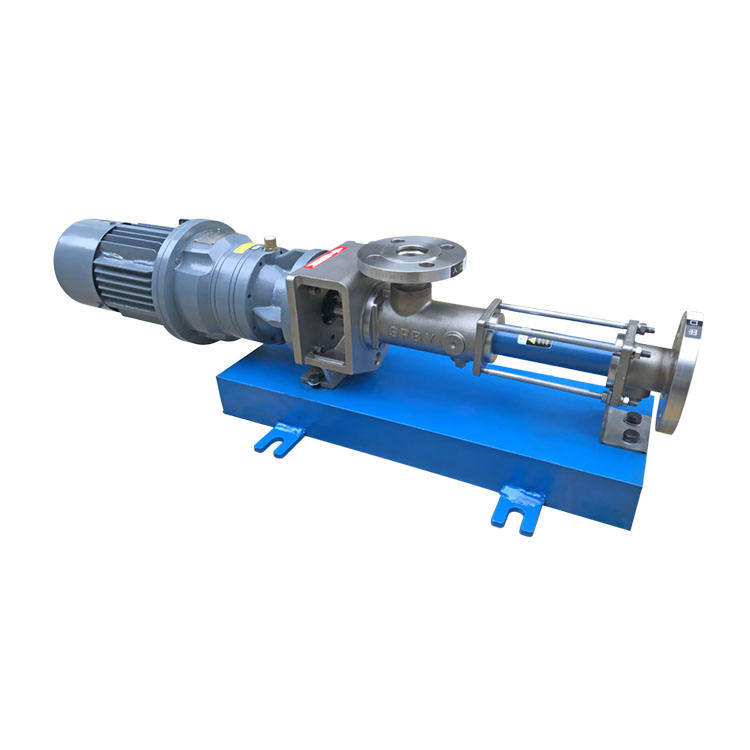

Netzsch NM045by01l06b What is a progressive cavity pump? Name : Progressive Cavity Pump(Single Screw Pump)Material :Progressive cavity pump parts, including the screw and helical rotor, are usually made of corrosion-resistant materials like 304SS or 316L stainless steel.Model : See photo model-01 / model-02(equal to NETZSCH series)Applicable medium : For any medium with or without solid…