Progressive cavity pumps are part of the positive displacement pump family. Each of the positive displacement pumps we have covered in the previous Quick and Dirty Guides (external gear, internal gear, rotary lobe, peristaltic, and diaphragm) have unique designs and capabilities. The progressive cavity pump is no different.

What is a progressive cavity pump?

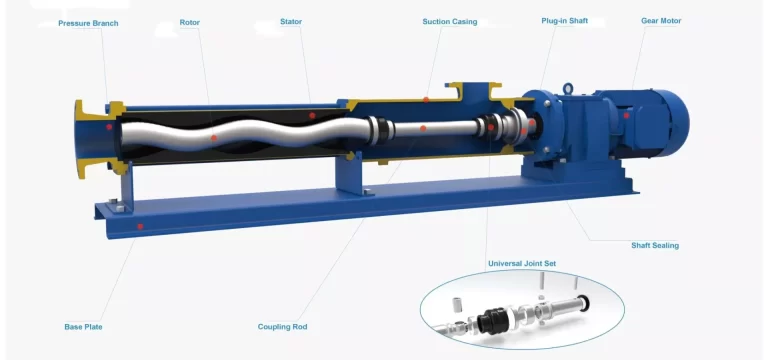

Progressive cavity pumps are characterized by a helical shaped rotor and flexible or rigid formed elastomer stator that pumps viscous liquids at high pressures.

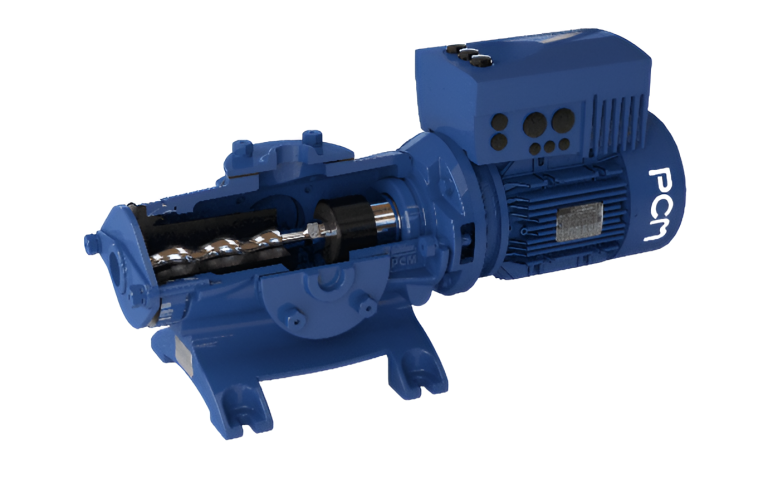

A progressive cavity pump is a type of positive displacement pump that uses a rotating screw-shaped rotor within a stator to move fluid through the pump. It is known for its ability to handle viscous fluids and provide a steady, pulsation-free flow.

How Small Progressive Cavity Pump work?

A small progressive cavity pump works by utilizing a helical rotor and a stator to create a pumping action. The rotor, typically composed of a single helix or multiple helical lobes, rotates within the stator, which has a matching internal helical shape. As the rotor turns, cavities are formed between the rotor and stator surfaces, creating a series of sealed chambers.

When the rotor rotates, the cavities progress from the suction side to the discharge side of the pump, carrying the fluid with them. This displacement action pushes the fluid from the inlet to the outlet of the pump. The fluid is continuously trapped within the cavities and displaced in a uniform and steady flow, without pulsations.

The small size of the progressive cavity pump allows it to be used in various applications, including low flow rate situations or when pumping viscous fluids, such as oils, slurries, and polymers.

What Small Progressive Cavity Pump Great For?

Unlike some positive displacement pumps that lose efficiency with low viscosity fluids, progressive cavity pumps easily handle both low and highly viscous material. They’re also good for small, shear sensitive solids like fruits and vegetables. They are specifically designed to handle abrasive and corrosive fluids.

Small Progressive Cavity Pump Best Application?

Progressive cavity pumps are used in a wide range of applications from wastewater treatment, to oil, to food and beverage. Here are just a few of the applications where a progressive cavity could be found:

- Slurry and sludge transfer

- Oils

- Cosmetics, creams, and lotions

- Paint, varnish

- Adhesives

- Fruits and vegetables

The progressive cavity pump is ideal for many applications across a wide spectrum of industries. Think it might be right for yours? Make sure you get the right pump for the job by talking to an experienced engineer. If you need help selecting the right pump for your application, ask us about it! We gladly provide technical assistance to businesses in Wisconsin and Upper Michigan.

People Also Ask

Send Your Enquiry :