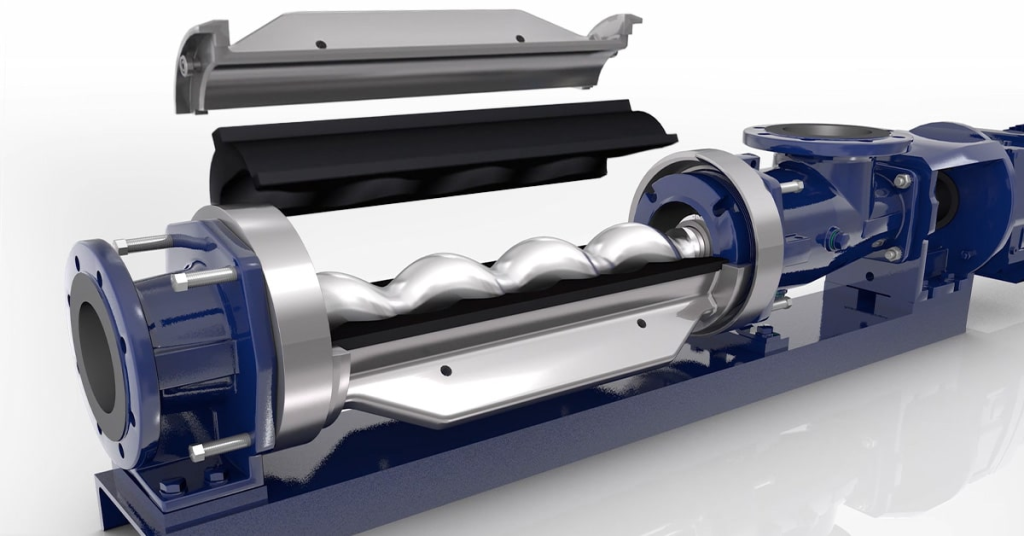

Working principle

The working principle of the Seepex BN26-6L stator is based on advanced screw pump technology. When the pump is running, the rotor rotates inside the stator to form multiple closed fluid chambers, and the fluid is effectively transported between the inlet and outlet through the movement of the screw. This method allows the pump to handle liquids of different viscosities without the phenomenon of gas entrainment or liquid backflow.

Thanks to the excellent design of the Seepex BN26-6L stator, the flow rate and pressure of the pump can be maintained at the optimal level, especially for occasions with high flow and pressure requirements. Its continuous conveying characteristics ensure the stability of the production process and greatly reduce the losses caused by uneven liquid flow.

Main features

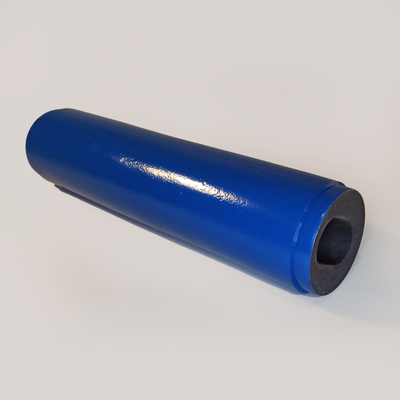

The design of the seepex BN26-6L stator fully considers the various needs of the pump and has the following significant features:

Easy to install and maintain: seepex takes into account the convenience of users when designing. The installation and maintenance of the stator are relatively simple, which is convenient for users to carry out daily maintenance and replacement.Superior sealing performance: seepex BN26-6L stator has been carefully optimized in sealing design, which effectively reduces leakage and improves the working efficiency of the pump.Strong adaptability: The stator can adapt to various types of fluids, including corrosive liquids and high-temperature fluids, and is suitable for a variety of industrial application scenarios.High wear resistance: The stator is made of high-performance materials and can withstand long-term wear and tear. It is suitable for environments with high fluid viscosity or containing solid particles.

Application areas

seepex BN26-6L stator is widely used in many fields. Here are some of the main applications:

- Chemical industry

In the chemical industry, pumps often need to handle various corrosive and high-temperature fluids. The corrosion resistance and high-temperature stability of seepex BN26-6L stator make it an ideal choice for chemical production. It can maintain good performance under harsh conditions to ensure the safety and stability of the production process. - Food and beverage industry

The food processing industry has extremely high requirements for the hygiene and safety of equipment. The seepex BN26-6L stator is designed to meet food safety standards and can effectively handle food ingredients such as syrups, dairy products, etc., ensuring product quality and safety. - Wastewater treatment

During wastewater treatment, pumps need to handle complex fluids containing solid matter and chemicals. The high wear resistance and good sealing performance of the seepex BN26-6L stator make it very suitable for this field and can effectively improve the efficiency of wastewater treatment. - Manufacturing

Many processes in the manufacturing industry require high-performance pumps to complete liquid transmission. With its strong adaptability, the seepex BN26-6L stator is widely used in multiple process flows such as injection molding and painting.

people also ask

Fill up and submit the below inquiry form, or directly write us an email: info@pumpvv.com