Application Fields

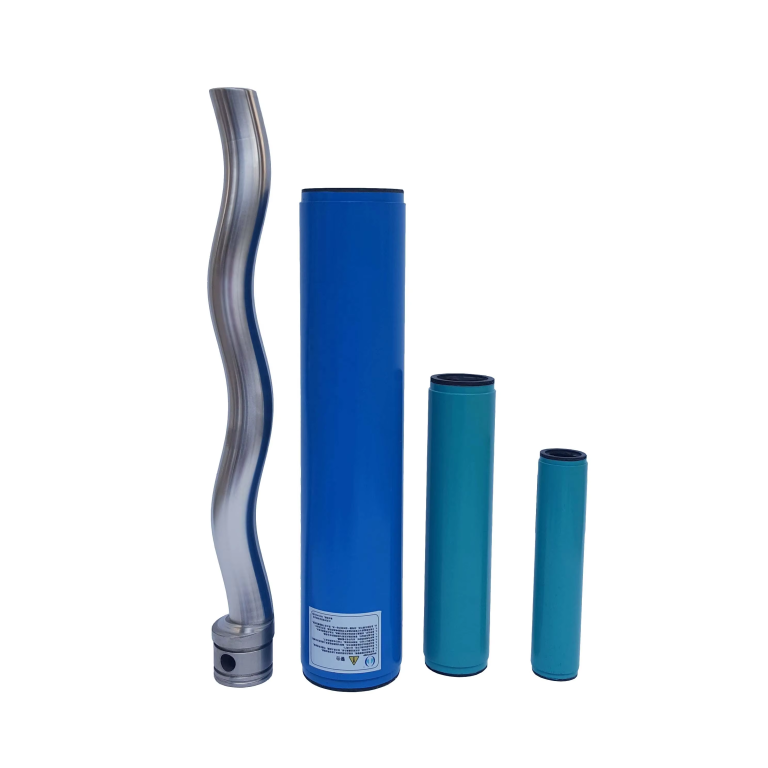

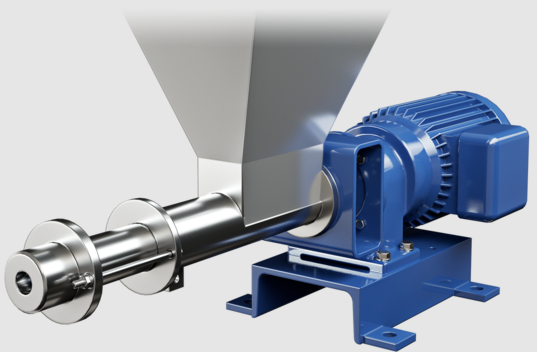

Seepex BN26-6L rotor is widely used in many industries. The following are some typical application scenarios:

- Chemical Industry

In the chemical industry, pumps often need to transport viscous chemicals. BN26-6L rotor has become one of the important equipment in chemical production due to its good corrosion resistance. - Water Treatment

In the wastewater treatment process, Seepex BN26-6L rotor can effectively transport sewage containing solid particles, providing reliable support for sewage treatment. - Food and Beverage Industry

The food industry has extremely high requirements for pump hygiene. The Seepex BN26-6L rotor uses food-grade materials to ensure that the product is not contaminated during processing. - Pharmaceutical Industry

In the pharmaceutical industry, pumps need to have precise control of fluids. The stable performance of the BN26-6L rotor makes it widely used in pharmaceutical production.

Performance Advantages

Efficient Delivery

The Seepex BN26-6L rotor performs well when conveying viscous or mixed media. Its design makes the fluid flow more smoothly in the pump, reducing energy consumption and improving overall work efficiency.

High Durability

The rotor can withstand extreme operating conditions, including high temperature and high pressure environments. Even in fluids containing solid particles, the Seepex BN26-6L rotor can still maintain excellent performance.

Easy Maintenance

Seepex's design concept focuses on easy maintenance. The BN26-6L rotor is easy to disassemble and assemble, which facilitates daily maintenance of the factory and reduces downtime.

people also ask

Send Your Enquiry :