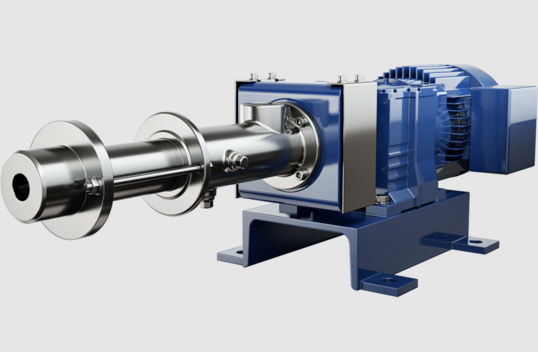

Design Features of the Rotor

The design concept of the seepex BN30-12T rotor is centered around efficiency and durability. Its spiral shape not only effectively propels fluids, but also performs well when subjected to high pressure and high viscosity fluids. In addition, the rotor is made of high-quality materials to ensure that it can still maintain good working performance under harsh environmental conditions. Unlike traditional pump rotor designs, the BN30-12T rotor helps reduce the energy required to convey the fluid, thereby improving the energy efficiency of the overall system.

Key Features

- High efficiency

The design of the seepex BN30-12T rotor optimizes the fluid conveying efficiency and can achieve a large flow rate with lower energy consumption. This is especially important for industrial equipment that needs to run for a long time, reducing energy costs and reducing environmental impact. - Durability

The rotor is made of wear-resistant materials and can cope with the challenges of high viscosity and corrosive fluids. This makes the seepex BN30-12T rotor perform well in many demanding applications, such as chemical, food processing and environmental engineering. - Easy maintenance

The design of the seepex BN30-12T rotor also takes into account the convenience of maintenance. Users can easily clean and replace it, reducing downtime and improving production efficiency.

Application areas

The wide application of the Seepex BN30-12T rotor makes it an indispensable component in many industries.

Here are some typical industries where this rotor is used:

- Food and beverage industry: In this industry, hygiene and fluid safety are crucial. The BN30-12T rotor can efficiently convey a variety of food fluids, such as juice, syrup, etc., while meeting strict hygiene standards.

- Chemical industry: The rotor can handle a variety of chemicals, including corrosive and high-viscosity fluids. Its corrosion-resistant material selection makes it superior in such applications.

- Wastewater treatment: In sewage and wastewater treatment processes, the BN30-12T rotor is used to convey liquids containing solid particles to ensure effective treatment and discharge of the fluid.

people also ask

Send Your Enquiry :