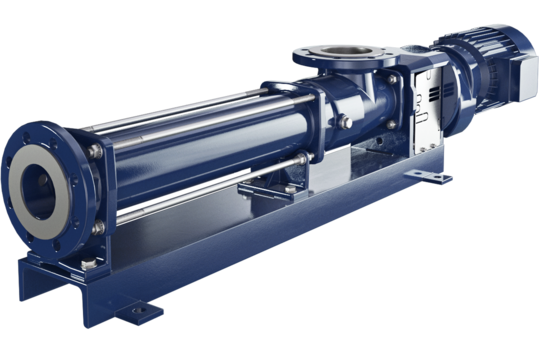

Parameters

- Model: BN30-12T

- Drive mode: Electric

- Scope of application: Oil transportation

- Pressure: 0.6Mpa

- Voltage: 380V

- Number of impellers: Single stage

- Lift: 60m

- Transport medium: Oil

- Impeller structure: Single impeller

- Material: Cast iron

- Brand: seepex

Introduction to BN30-12T

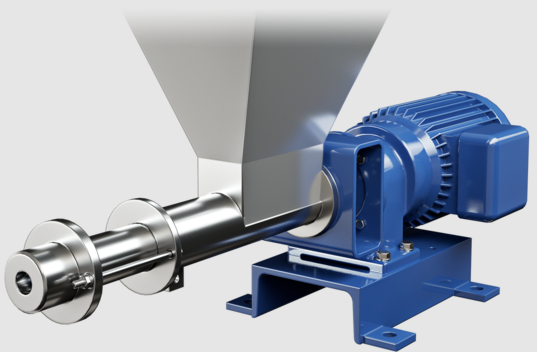

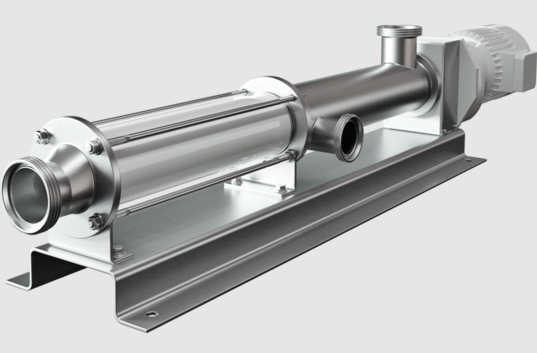

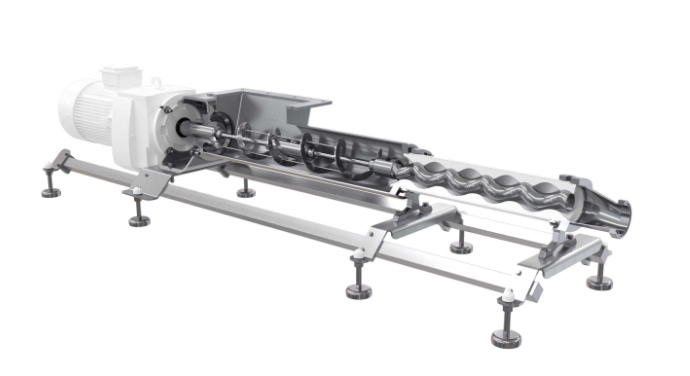

The rotor is made of highly wear-resistant materials, has excellent corrosion resistance and durability, and can operate stably under high loads and harsh environments. Its clever geometric design helps reduce the shear force of the fluid during transportation, ensuring that the quality of the fluid is not damaged. The construction of the stator emphasizes good sealing and uses elastic materials to effectively prevent leakage.

A prominent feature of the Seepex BN30-12T pump is its efficient fluid delivery capability. Users can flexibly adjust the pump speed according to actual process requirements to achieve different flow and pressure settings. This flexibility enables the BN30-12T to efficiently cope with fluid delivery challenges in various industrial processes.

The Seepex BN30-12T is widely used in many industries, including chemical, food, pharmaceutical, sewage treatment, etc. In a variety of fluid delivery occasions, especially when high viscosity and solid particles need to be handled, the BN30-12T performs well.

The maintenance and care of the BN30-12T is also relatively simple. When users conduct regular inspections, maintenance can be completed quickly. This low maintenance requirement not only improves production efficiency, but also saves operating costs for enterprises.

people also ask

Fill up and submit the below inquiry form, or directly write us an email: info@pumpvv.com