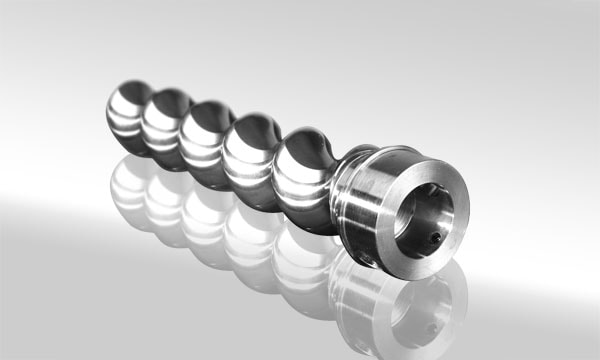

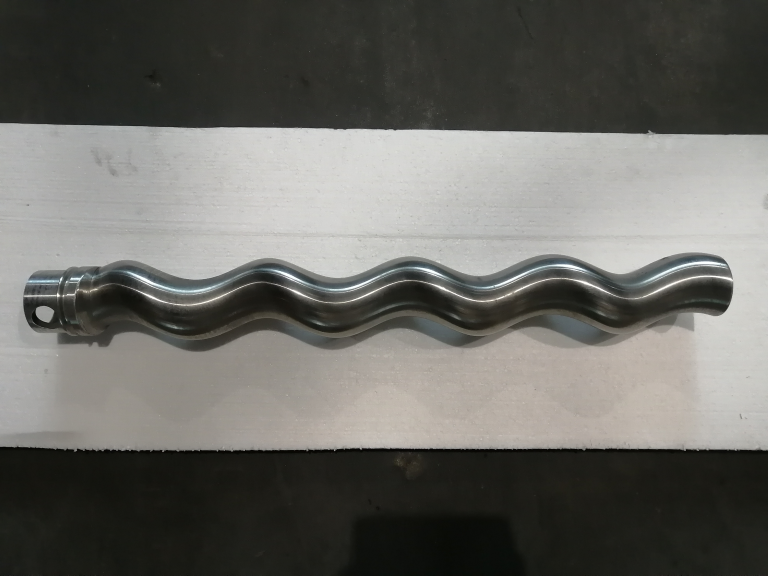

BN52-12L rotor seepex

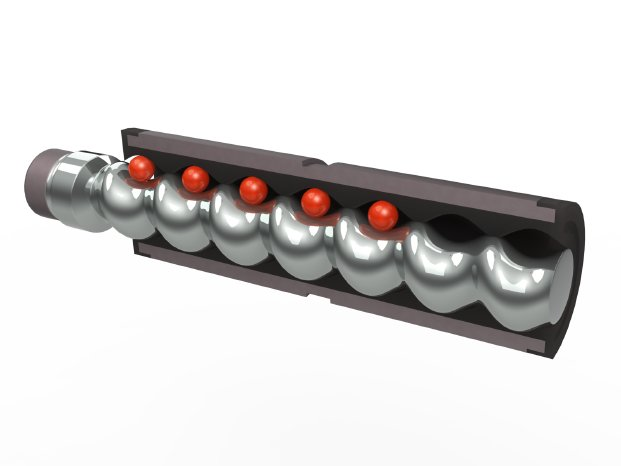

What is seepex BN52-12L Rotor? seepex BN52-12L is a rotating component of a screw pump widely used in the industrial field. As the core component of the screw pump, it is responsible for converting the input power into the fluid delivery power and is the key to determining the performance of the pump. Features of…