Introduction

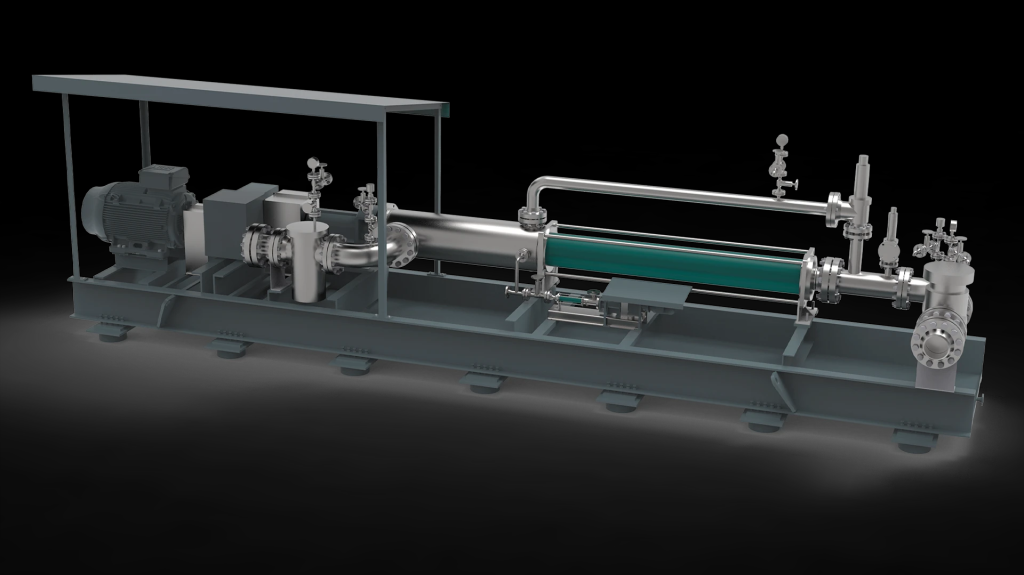

The multiphase progressive cavity pump is an innovative solution commonly used in various industries, particularly in oil and gas extraction. This type of pump is designed to handle multiple phases of fluid, including liquids, gases, and solids, making it versatile and efficient for challenging applications.

Working Principle

The function of a multiphase progressive cavity pump relies on a unique rotor and stator mechanism. The rotor is helical in shape and rotates within a stationary stator. As the rotor turns, it creates cavities that transport the fluid through the pump. This design allows for smooth and continuous flow, even with varying viscosities and phases.

Key Features

- Versatility

- Capable of handling different types of fluids, including slurries and viscous liquids.

- Effective in environments with varying pressure and temperature conditions.

- Efficiency

- Provides a constant flow rate regardless of the pressure changes in the system.

- Minimizes pulsation, leading to less wear and tear on the pump and connected systems.

- Low Maintenance

- Fewer moving parts compared to other pump types reduces maintenance needs.

- Long-lasting materials used in construction enhance durability.

- Compact Design

- The compact size allows for easy installation in tight spaces.

- Lightweight design facilitates transportation and setup.

Applications

Multiphase progressive cavity pumps are utilized in various sectors, including:

- Oil and Gas Industry

- Transporting crude oil, water, and gas mixtures from production sites to processing facilities.

- Wastewater Treatment

- Moving sludge and other viscous materials through treatment systems.

- Food and Beverage

- Pumping viscous products such as sauces, syrups, and pastes without damaging the product.

- Chemical Processing

- Handling corrosive and abrasive materials safely and efficiently.

Advantages

- High Tolerance to Solids

- The pump can handle solid particles without clogging, making it suitable for harsh environments.

- Self-Priming Capability

- Can draw fluid from a lower level, which simplifies the installation process and reduces the need for additional equipment.

- Adaptability

- Easily adjustable to meet specific operational requirements, such as flow rates or pressure levels.

Conclusion

The multiphase progressive cavity pump is a crucial technology for industries requiring reliable fluid transfer solutions. Its unique design and versatility make it an invaluable asset in handling complex fluid mixtures. With its numerous advantages, this pump type continues to play a significant role in enhancing operational efficiency across various applications.

Send Your Enquiry :