Stainless Steel Dosing Pumps for Dosing and Conveying

Q=0.1-250 ml/h

P=0~2.4 Mpa (0~348 psi)

Measurement accuracy: <1%

Stainless Steel Dosing Pump for Dosing and Conveying?

The dosing pump is a kind of progressive cavity pump, which is specially designed for small flow liquid transportation.

Chemical dosing pump structure is completely suitable for smooth and low pulsation medium transportation, and can accurately transport and measure corrosive and anti-corrosion chemicals.

Because it is widely used in medicine liquid metering, adding and dispensing machines, it is usually used as metering dosing pump.

[video_lightbox_youtube video_id=”JWkoODah0vY;rel=0″ width=”640″ height=”480″ alt=”Sludge Screw Pump” anchor=”https://pumpvv.com/wp-content/uploads/2023/03/pump-cover1.png”]

The Features Of Stainless Steel Dosing Pumps

- No pulsation, small flow, precise metering and transportation, and the metering accuracy is 1%.

- It can transport abrasive slurry with particles and shear sensitive medium with high concentration, high viscosity and high solid content.

- The flow rate is proportional to the rotating speed, with simple structure, low maintenance cost, convenient installation and movement, variable frequency control and servo motor drive.

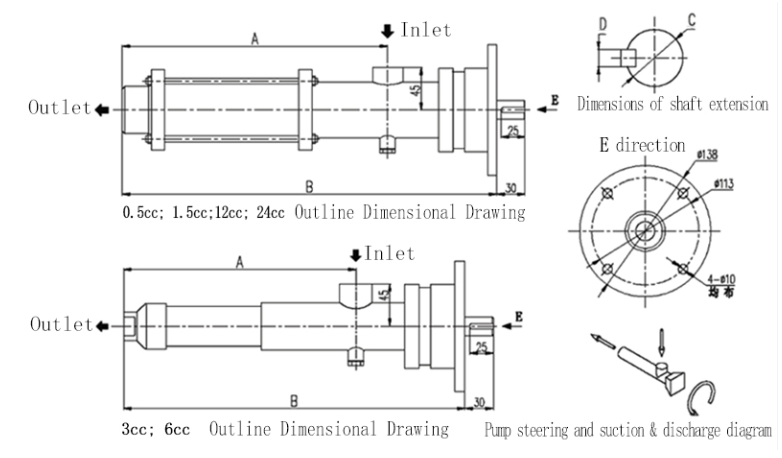

- The axial dimension is small, which is 1/3-1/2 shorter than the pump with general structure, and the pump tends to be miniaturized.

- The influence of temperature is small and the working torque is low.

- Jacket insulation structure is adopted, which is widely used in chocolate and candy making process to transport high viscosity food.

- The self-absorption capacity is strong, reaching 7-8M, and the flow rate is stable even at very low speed. Usually used for measuring dosing pump.

- Low energy consumption, suitable for making micro pump, even 40W motor can work normally.

- Maintenance-free and easy to maintain.

- Compact structure and high efficiency.

Transportable media performance characteristics:

- The fluid medium contains or does not contain solid materials;

- Medium and low viscosity (20 000mpas);

- Thixotropy and expansibility;

- Abrasive property (PH 0-14);

- Lubricating or non-lubricating;

Stainless Steel Dosing Pumps Applications

Widely used in food, chemical industry, pharmacy, quantitative dosing of sewage treatment system, electronics, batteries, energy, cosmetics and other industries, especially highly automated professional metering and coating systems.

Such as: lithium battery coating, automobile sealing glue coating, laboratory slurry, pharmaceutical mixture ratio, metering and subpackaging of pharmaceutical slurry, conductive paint coating for solar panels, and glue coating for electronic industry.

Dosing Progressing Cavity Pump Performance Parameter List

| Model | Pressure(Mpa) | 100 rpm (liter/h) | 200 rpm (liter/h) | 300 rpm (liter/h) | 400 rpm (liter/h) | Motor power(KW) |

|---|---|---|---|---|---|---|

| RV0.43 | 0.6 | 4.5 | 9 | 15.5 | 18 | 0.25 |

| RV0.83 | 0.6 | 9 | 18 | 27 | 36 | 0.37 |

| RV1.53 | 0.6 | 16.8 | 33.6 | 50.4 | 80 | 0.37 |

| RV3.2 | 0.6 | 33.7 | 67.4 | 101.1 | 144.8 | 0.55 |

| RV6.2 | 0.6 | 67.5 | 135 | 202.5 | 270 | 0.55 |

| RV12.2 | 0.6 | 135 | 270 | 405 | 540 | 0.55 |

Dosing Progressing Cavity Pump Attention

0.4, 0.8, and 1.5 in this product model are expressed as 0MPa,400r/min, and its flow rate is 0.4 liters, 0.8 liters, and 1.5 liters per minute, while the latter number 3 is expressed as a three-stage pump, which can generate 1.6-1.8MPa working pressure.

In the same way, the former number of 3.2, 6.2 and 12.2 indicates that its flow rate is 3 liters, 6 liters and 12 liters per minute under the condition of 0MPa400r/min, and the latter number 2 indicates a secondary pump, which can generate 1.0-1.2MPa working pressure.

0.4: the flow rate is 400r/min and 0.4l under 0 pressure

3: The pump is of Grade 3

People Also Ask

Send Your Enquiry :