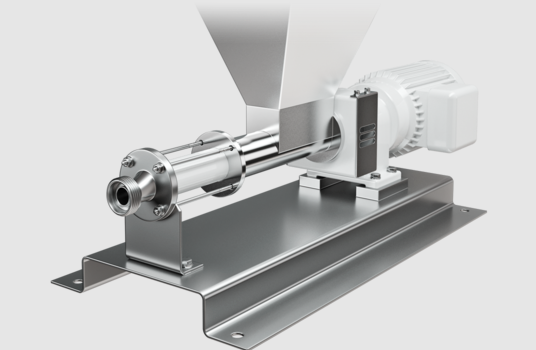

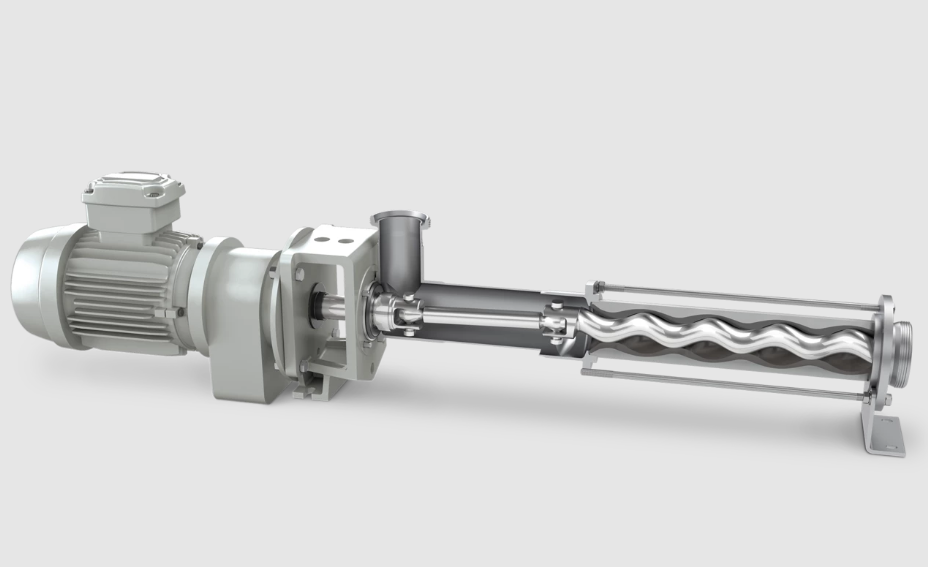

NEMO® BH Sanitary Advanced Pump in Compact Block Design

[wpseo_breadcrumb]

NEMO® BH Sanitary Advanced Pump

The NEMO BH hygienic pump in compact block design is used for hygienic applications in the food,pharmaceutical, cosmetic and chemical/biochemical industries because of its optimal process characteristics.

Application of the NEMO® BH Sanitary Advanced Pumps

The NEMO® BH Sanitary Pump is employed in the food products, pharmaceutical, cosmetic and chemical/biochemical industries for sanitary applications and optimal cleaning. The important capabilities include, the continuous, pressure-stable, gentle and low-pulsation pumping and metering in proportion to speed. The block pump construction with flanged drive is particularly compact and economical to operate.

Features of the NEMO® BH Sanitary Advanced Pumps

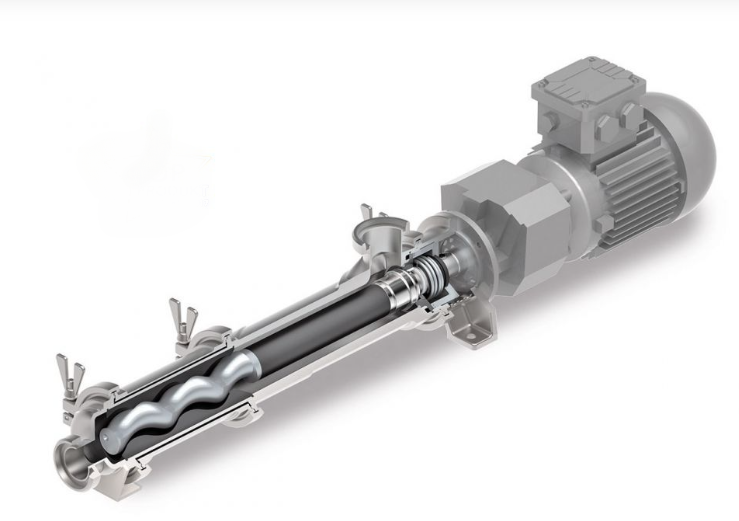

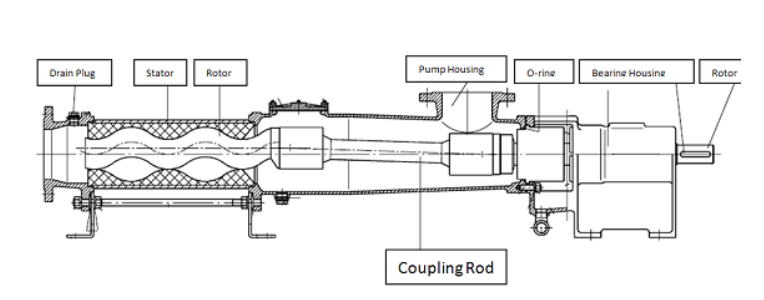

- continuous low-pulsation pumping unaffected by fluctuations in pressure and viscosity

- capacity in proportion to rotation speed with high metering precision over a broad rotational-speed range

- high suction and pressure capability without valves

- reversible pumping direction

- stator with chamfered entrance for optimal filling of the conveying chamber

Advantages of the NEMO® BH Sanitary Advanced Pump

- shaft seals suitable for food products with compression-proof bolted seal casing enable reversal of the direction of rotation, and so the direction of pumping, up to the maximum pump pressure

- streamlined, crevice-free housing model prevents product settling

- all product-contacting surfaces are polished to prevent product build-up and facilitate cleaning

- the pump housing and stator can be optionally heated

Take advantage of our decades of experience and expertise in positive displacement pump manufacture.

Your edge – process stability even under great demands!

NEMO® BH hygienic pump meets numerous hygiene guidelines

NEMO® pumps are designed, manufactured and tested in accordance with FDA (Food and Drug Administration) as well as EU VO 1935/2004. In addition, NEMO® hygienic and aseptic progressing cavity pumps meet the requirements of the 3-A Sanitary Standard of the USA and are GOST-R certified (certificate of conformity for Russia). The NEMO® BH is particularly compact and economical in block construction with flanged drive.

[video_lightbox_youtube video_id=”5PYaQI_gYHM&rel=0″ width=”640″ height=”480″ alt=”Sludge Screw Pump” anchor=”https://pumpvv.com/wp-content/uploads/2023/04/BH-Sanitary-Advanced-Pump-in-Compact-Block-Design-1.png”]

People Also Ask

Send Your Enquiry :