NEMO BY Progressing Cavity Pump

NEMO BY Progressing Cavity Pumps convey a wide array of substances or very precisely meter substances in numerous industrial applications. From low viscosity substances to products barely capable of flowing, with or without solid content, shear-sensitive, sticky or abrasive with the NEMO® BY, even difficult substances are pumped gently and with low pulsation.

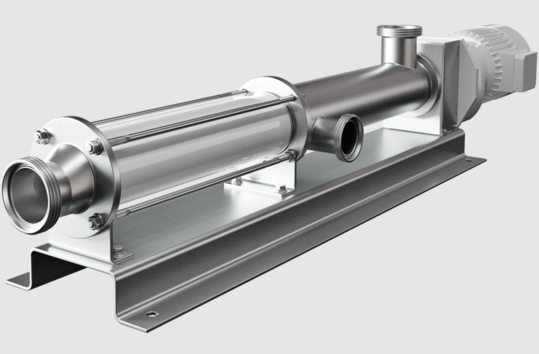

NEMO® BY Pump: Compact and Economical Block Construction with Direct Coupled Drive

In block construction with a direct coupled drive, this NEMO pump is particularly compact and economical. The NEMO Pump also offers you low investment and low operating and maintenance costs. Four rotor/stator geometries are available to cover a wide range of products and applications. Contact us and we will help you find the optimal solution for your application.

NEMO® BY Progressing Cavity Pumps offer you:

- gentle product handling

- pump connections in accordance with national and international standards, as well as in specially designed models

- easy serviceability

Features of the NEMO® BY Progressing Cavity Pump

- continuous low-pulsation conveyance unaffected by fluctuations in pressure and viscosity

- capacity in proportion to rotation speed with precision metering over the entire rotational-speed range

- high pressure capability without valves

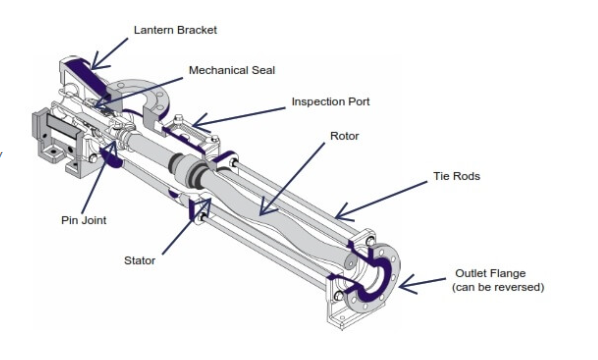

- no dead zone – mechanical seal is positioned in the path of the product, eliminating the need for flushing

- short drive shaft and pump pedestal offer high stability for mechanical seal installation

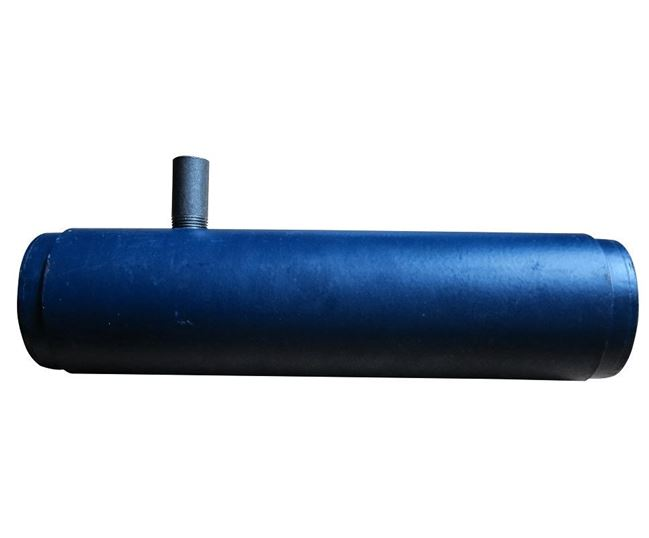

- stator is easily changed

Advantages of the NEMO® BY Progressing Cavity Pump

- variable modular system

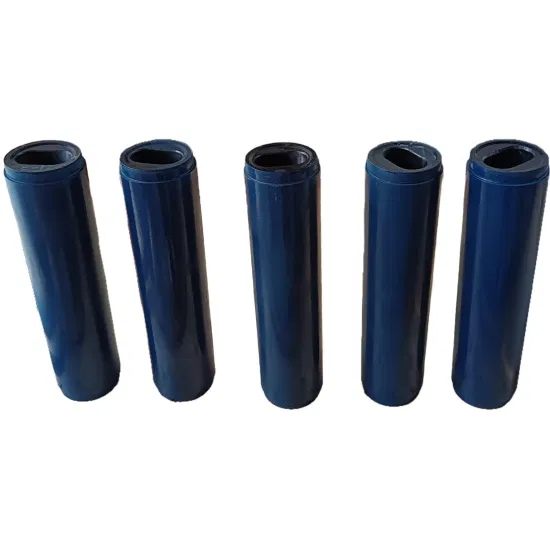

- various rotor/stator geometries and a broad range of materials

- robust and compact block construction

- the right joint for any application

- standard mechanical seal, other seals optional

Low costs with the NEMO® BY progressing cavity pump

In addition, the progressing cavity pump guarantees flow rates proportional to speed with high dosing accuracy over the entire speed range. In block design with flanged drive, this NEMO® pump is especially compact and economical. Moreover, the NEMO® BY is distinguished by its low investment, operating and maintenance costs. Four rotor/stator geometries are available for the various products and applications.

[video_lightbox_youtube video_id=”aCl7E05nnZc&rel=0″ width=”640″ height=”480″ alt=”NETZSCH NEMO BY Progressing Cavity Pump ” anchor=”https://pumpvv.com/wp-content/uploads/2023/04/NEMO®-BF-Open-Throat-Progressing-Cavity-Pump-1.png”]

Pump curve

PC Pump curves are different to a centrifugal curve as it is linear demonstrating the units ability to handle liquids of varying viscosities with little impact on pump performance, with the bottom axis being speed rather than flow as flow is proportional to speed. Unit speed is much lower than centrifugal, operating from as little as 50rpm

progressive cavity pump curve sludge/progressive cavity pump performance curves

People Also Ask

Send Your Enquiry :