Progressive cavity pumps are widely used in various industries for their ability to handle viscous fluids and maintain a steady flow. However, one critical aspect of their operation is the Net Positive Suction Head (NPSH) margin. Understanding NPSH margin is essential for ensuring efficient pump performance and longevity.

What is NPSH?

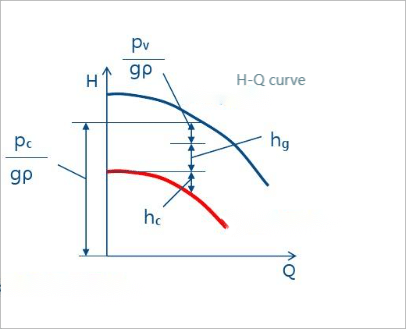

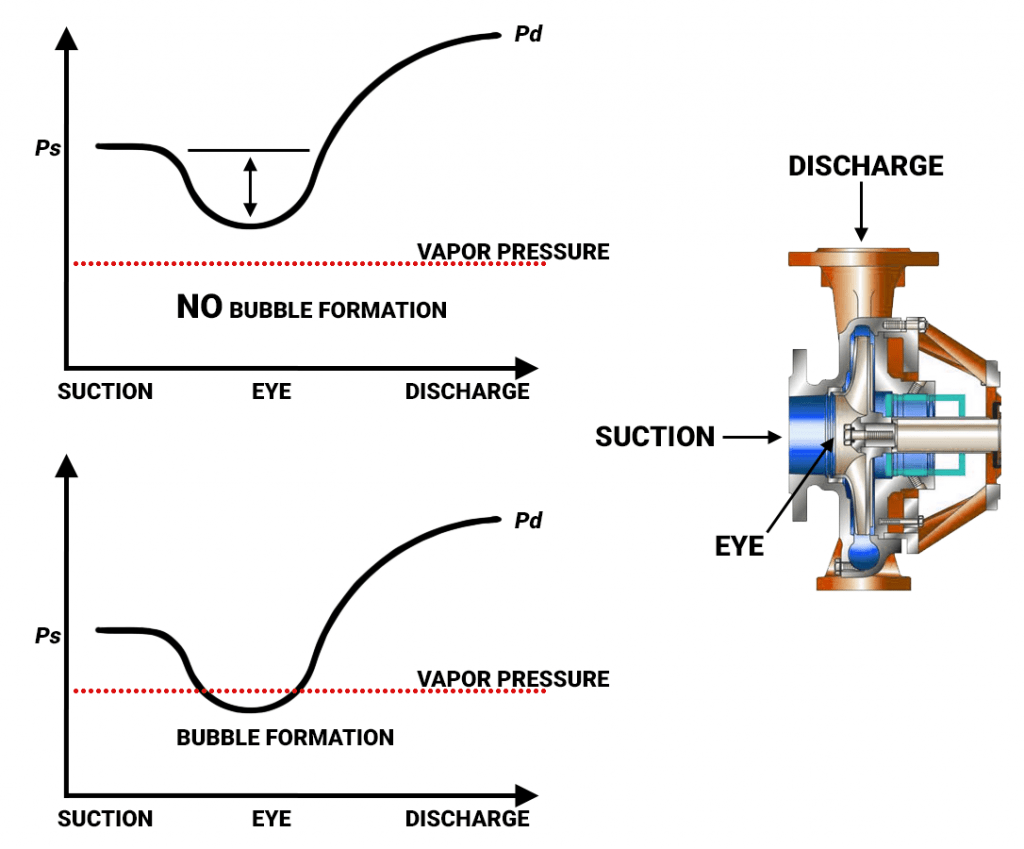

NPSH is a measure of the pressure available at the pump inlet to prevent cavitation. Cavitation occurs when the pressure in the pump drops below the vapor pressure of the fluid, leading to the formation of vapor bubbles. These bubbles can collapse violently, causing damage to the pump and reducing its efficiency.

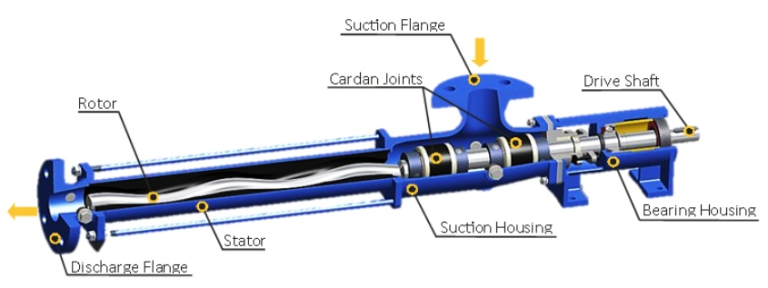

Components of NPSH

- NPSH Available (NPSHa): This is the actual pressure available at the pump suction. It takes into account the height of the fluid, atmospheric pressure, and any friction losses in the piping system.

- NPSH Required (NPSHr): This is the minimum pressure required at the pump inlet to avoid cavitation. It is determined by the pump design and is usually provided by the manufacturer.

Importance of NPSH Margin

The NPSH margin is the difference between NPSHa and NPSHr:

- Safety Factor: A positive NPSH margin ensures that the pump operates safely without cavitation. Insufficient margin can lead to pump damage and decreased performance.

- Operational Efficiency: Maintaining a healthy NPSH margin allows the pump to function at its best, ensuring steady flow and minimizing energy consumption.

- Longevity of Equipment: Reducing the risk of cavitation directly correlates with the lifespan of the pump and associated components, resulting in lower maintenance costs.

Factors Affecting NPSH Margin

Several factors can influence the NPSH margin of a progressive cavity pump:

- Fluid Characteristics: The viscosity and temperature of the fluid can impact the NPSHa. Higher viscosity fluids generally create more friction losses, reducing available pressure.

- Piping Design: The layout and diameter of the suction piping can significantly affect friction losses. Long runs or bends in the piping will increase resistance and reduce NPSHa.

- Elevation: The vertical distance between the fluid source and the pump affects NPSHa. A higher elevation can lower the available pressure, potentially leading to cavitation.

- Pump Speed: Increasing the pump speed can raise the NPSHr, necessitating a larger NPSH margin to avoid cavitation.

Best Practices for Maintaining NPSH Margin

To ensure a sufficient NPSH margin, consider the following practices:

- Regular Monitoring: Keep track of the pump performance and any changes in fluid characteristics. Regular checks can help identify issues before they become critical.

- Optimize Piping Layout: Design the suction piping to minimize bends and restrictions, ensuring smooth flow to the pump.

- Select Appropriate Pump: Choose a pump with a suitable NPSHr for the specific application. Consulting with manufacturers can provide valuable insights.

- Control Fluid Viscosity: If possible, manage the fluid temperature and composition to maintain optimal viscosity levels.

In conclusion, understanding and maintaining the NPSH margin is vital for the efficient operation of progressive cavity pumps. By taking proactive steps to manage this aspect, operators can enhance performance, reduce maintenance costs, and extend equipment lifespan.

People also ask

Send Your Enquiry :