Key Considerations for Selecting a Small Metering Pump: Boost Accuracy & Efficiency

Small metering pumps have increasingly become an indispensable key device in modern society. It is also called micro metering pumps or mini metering pumps.

In industrial production and laboratory research, we often face a seemingly minor yet crucial challenge: how to accurately transfer liquids with extremely low flow rates. Whether adding trace additives or conducting precise chemical analysis, traditional transfer methods often fail to meet high-precision requirements. At this point, a device specially designed for this purpose—the low-flow metering pump, that is the small metering pump—becomes an indispensable key tool. In recent years, such pump equipment capable of precise control has gained extensive attention and application in the market.

1. What is a Small Metering Pump?

Simply put, a small metering pump is a special type of pump that can accurately control and transfer liquids in extremely small volumes. Its “low flow rate” generally refers to a delivery range of milliliters per hour or even less. Unlike ordinary pumps that pursue high flow rates, it focuses more on achieving stable and highly repeatable delivery accuracy at an extremely small flow scale.

2. Characteristics of Small Metering Pumps.

- Small Metering pumps feature small size, light weight and compact structure, which enable easy installation and use in space-constrained environments.

- Small Metering pumps also have the characteristics of stable flow rate, adjustable pressure and corrosion resistance, which ensure the accuracy and safety of fluid transfer.

3. Application Scope of Small Metering Pumps.

Small metering pumps are suitable for various liquids, including water, oil, solvents, acid-base chemicals and liquid food(sanitary pumps), and applicable to various liquid operation scenarios such as metering, transfer, mixing and distribution. They can be used in occasions requiring high precision and stability for applications like liquid metering and subpackaging, process control, long-distance transfer, circulating liquid supply, mixing and homogenization. Meanwhile, this type of product has the advantages of high precision, stable operation and easy installation, and is widely used in various industrial occasions and fields such as liquid distribution and batching.

4. Types of Small Metering Pumps.

4.1 Gear Pumps.

Gear pumps are a common type of small metering pump with a simple and reliable structure, renowned for accurately measuring and transferring liquids of various viscosities. The main advantages of gear pumps include stable quality, wear resistance, high reliability, strong self-priming capacity and light weight. Gear pumps are mainly suitable for some low-viscosity and high-concentration liquids, such as syrup, crude oil and fuel oil.

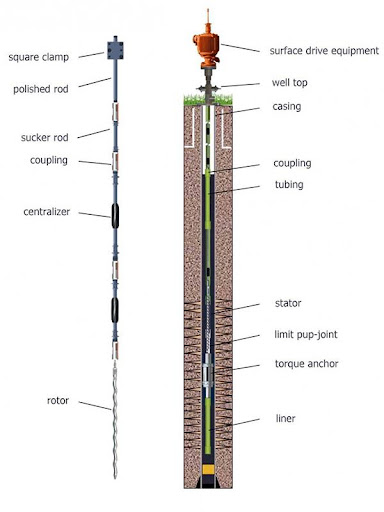

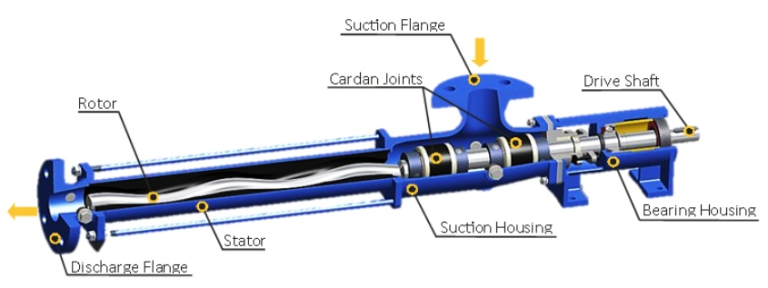

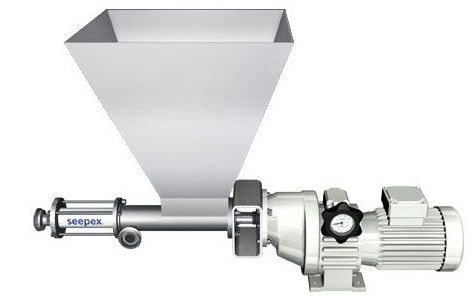

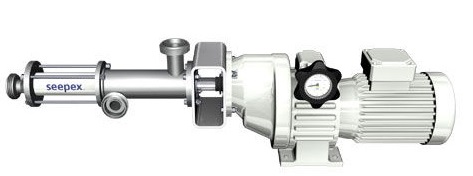

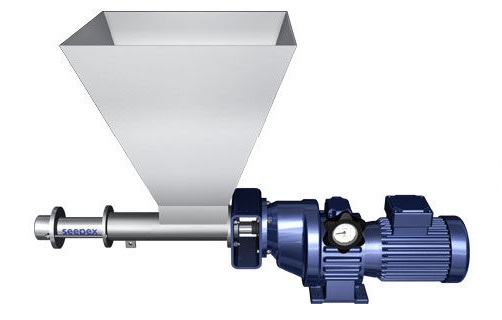

4.2 Screw Pumps.

Screw pumps are positive displacement pumps characterized by high precision, stable operation, low noise and large exhaust capacity. Their working principle is to transfer liquid from the pump inlet to the outlet through the rotation of screws in the pump cavity. Screw pumps are mainly suitable for pumpable low-viscosity liquids such as gasoline, ethanol and engine oil.

4.3 Diaphragm Pumps.

Diaphragm pumps belong to membrane pumps and are also a type of positive displacement pump. They have the advantages of energy saving, high efficiency, stable operation and convenient construction and maintenance. Diaphragm pumps adopt two mutually isolated diaphragms, and transfer the liquid on both sides through the diaphragm by means of emptying via compression air source. Diaphragm pumps have a wide application range and are mainly suitable for some corrosive liquids, high-temperature liquids and granular slurry liquids.

4.4 Piston Pumps.

Piston pumps are metering pumps that push liquid through the movement of pistons. They push liquid to the pump head by compressing and driving the piston, and can adapt to higher pressure than screw pumps. Piston pumps have the advantages of smooth operation, stable flow rate and high reliability. They are mainly suitable for conveying some high-concentration liquids such as honey and molasses.

4.5 Centrifugal Pumps.

Centrifugal pumps are metering pumps that push liquid to flow by generating liquid pressure through centrifugal force. They feature small size, convenient construction and wide application. Their working principle is to drive the impeller to rotate through the rotation of the motor to discharge liquid. Centrifugal pumps are suitable for pure water, chemicals, water treatment, cooling water and other media.

It is evident that different types of small metering pumps have their unique advantages and functions. In use, it is essential to select different types of pumps according to different needs to ensure the best application effect.

5. Key Considerations for Selecting Low-Flow Micro Metering Pumps.

Selecting a suitable low-flow micro metering pump requires consideration of several key factors.

- First is the flow range. It is necessary to determine the required flow range according to the actual application. The selected pump should be able to cover this range with a certain margin reserved.

- Second is the precision requirement. Different applications have different precision requirements, so it is necessary to select the appropriate precision grade according to the actual needs.

- Third is the fluid properties. Fluid characteristics such as viscosity, corrosivity and solid content will affect pump selection. For example, high-viscosity fluids may require special types of pumps.

- Fourth is the working environment. Environmental conditions such as temperature, humidity and pressure will also affect pump performance, so it is necessary to select models suitable for specific environments.

- Fifth is the installation space. Micro metering pumps are usually used in space-constrained occasions, so it is necessary to confirm whether the pump size meets the installation requirements.

- Sixth is the control method. According to the requirements of automation level, manually controlled or automatically controlled models can be selected. Automatic control usually includes analog control, digital communication and other methods.

As a flow meter, small metering pumps have the advantages of high precision, good stability, small size and light weight. They are widely used in different industrial fields and become an important tool for various liquid metering, transfer and distribution work. Through above relevant introduction of small metering pumps, you can gain a deeper understanding of the characteristics and application scope of this type of product, providing comprehensive reference and guidance for your practical application.