[wpseo_breadcrumb]

Oil transfer pump refers to a type of pump specifically designed to transfer oil from one container to another.

The detailed introduction to oil transfer pump.

1.Functions & Applications.

The core function of an oil transfer pump is to convey oil from a lower position to a higher position, or from one storage device to another. It overcomes challenges such as height differences and pipeline resistance, ensuring the stable flow of oil within pipelines. This equipment is widely used in industries including petroleum and natural gas, industrial machinery, transportation, and engineering machinery.

2.Working Principle of Oil Transfer Pump.

An oil transfer pump converts mechanical energy into fluid pressure energy through mechanical or electric power, utilizing internal components such as pistons, gears, and screws. This enables the transfer of oil from a low-pressure zone to a high-pressure zone. Its working process typically consists of three stages: oil suction, compression, and discharge.

3.Common Types.

- Gear Oil Transfer Pump: It transports fluid through the meshing movement of gears. Suitable for conveying various lubricating fluids at temperatures not exceeding 70°C.

- Diaphragm Oil Transfer Pump: It delivers fluid by leveraging the reciprocating motion of a diaphragm. Ideal for transferring non-corrosive lubricating oil or other fluids that contain no solid particles or fibers.

- Plunger Oil Transfer Pump: It achieves oil suction and discharge via the reciprocating motion of a piston. When the piston moves downward, the inlet valve opens and the outlet valve closes, drawing oil into the pump body. When the piston moves upward, the inlet valve closes and the outlet valve opens, expelling the oil from the pump body.

- Centrifugal Oil Transfer Pump: It generates centrifugal force through the rotation of an impeller, flinging oil outward from the center to increase its pressure. Suitable for conveying low-viscosity oil.

4.Performance Parameters.

The performance parameters of oil transfer pumps vary by type, and typically include flow rate, pressure, operating temperature, and viscosity range. For example, the Groz 1:1 pneumatic oil transfer pump has a flow rate of up to 40 LPM (liters per minute), an operating pressure range of 30–150 PSI, and can handle medium-to-low viscosity oils with a viscosity rating of up to SAE 80.

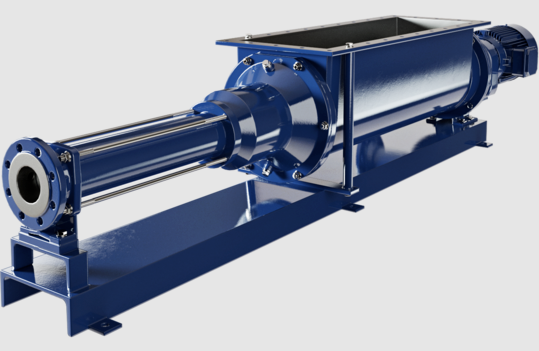

What is Screw Oil Transfer Pump.

A screw oil transfer pump is a type of positive displacement pump designed specifically for the efficient and stable transfer of oil and oil-based fluids. It relies on the meshing motion of screw rotors to transport the medium, and it is widely used in petroleum refining, petrochemical engineering, oil depot transportation, and mechanical lubrication systems.

1.Working Principle of Screw Oil Transfer Pump.

The screw oil transfer pump is mainly composed of rotors (single screw, twin screw, or triple screw) and a stator (for single screw pumps) or pump casing (for twin/triple screw pumps).

- When the drive device drives the rotor to rotate, the meshing of the screw rotors forms a series of sealed cavities that move continuously along the axial direction of the rotor.

- The oil entering the suction port is trapped in these sealed cavities, and as the rotor rotates, the cavities move steadily toward the discharge port without turbulence or backflow.

- When the sealed cavity reaches the discharge port, the oil is pushed out of the pump body, achieving continuous and uniform oil transfer.

The positive displacement structure ensures that the pump’s flow rate is almost proportional to the rotational speed, and it is less affected by changes in discharge pressure.

2.Key Features.

- Stable and smooth operationThe meshing motion of the screws is gentle, with low vibration and noise during operation. The oil flows in an axial direction without eddy currents, which can effectively reduce the shear damage to the oil medium and is suitable for conveying oil with high viscosity or containing a small amount of impurities.

- Strong self-priming capacityScrew oil transfer pumps have excellent self-priming performance, and most models can achieve self-priming without the need for additional priming devices, making them suitable for occasions where the suction port is higher than the liquid level of the oil tank.

- Wide viscosity adaptation rangeIt can handle oil with a viscosity range from low-viscosity diesel (2–100 mPa·s) to high-viscosity heavy oil, asphalt, and lubricating grease (up to 100,000 mPa·s), and the flow rate remains stable under different viscosity conditions.

- High pressure resistanceDue to the positive displacement design, the pump can generate high discharge pressure by increasing the rotational speed or the number of screw stages, meeting the requirements of long-distance or high-lift oil transfer.

3.Common Classification.

Screw oil transfer pumps are mainly divided into three categories according to the number of rotors:

| Type | Structure Characteristics | Application Scenarios |

|---|---|---|

| Single Screw Oil Transfer Pump | Consists of 1 helical rotor and a rubber stator with internal helical grooves; the stator and rotor form sealed cavities. | Conveying crude oil, residual oil, and oil with a small amount of solid particles; suitable for small-flow, high-pressure oil transfer systems. |

| Twin Screw Oil Transfer Pump | Two intermeshing screws rotate in the pump casing; no need for a rubber stator, with high mechanical strength. | Petroleum refining, oil depot loading and unloading, and large-flow oil pipeline transportation; suitable for medium to high viscosity oil. |

| Triple Screw Oil Transfer Pump | Composed of 1 driving screw and 2 driven screws; the structure is compact, and the sealing performance is better. | Precision lubrication systems of mechanical equipment, fuel supply systems of engines, and occasions requiring high cleanliness of oil. |

4.Application Fields.

- Petroleum and petrochemical industry: Transfer of crude oil, refined oil (gasoline, diesel, kerosene), lubricating oil, heavy oil, and asphalt in oil depots, refineries, and long-distance pipelines.

- Mechanical engineering: Providing lubricating oil for large machinery (such as turbines, compressors, and rolling mills) and conveying hydraulic oil in hydraulic systems.

- Marine engineering: Fuel supply and lubricating oil circulation systems for ship engines; the pump’s compact structure and corrosion resistance can adapt to the marine environment.

- Food and pharmaceutical industry: Transfer of edible oil, vegetable oil, and other oil-based raw materials (using food-grade screw rotors and casings to meet hygiene standards).

5.Installation and Maintenance Notes.

- Installation requirements: The pump should be fixed firmly to reduce vibration; the suction pipeline should be short and straight, and equipped with a filter to prevent large particles from entering the pump body and damaging the screw rotors.

- Lubrication management: The bearing and sealing parts of the pump need to be lubricated regularly; for oil transfer pumps conveying corrosive oil, corrosion-resistant materials (such as stainless steel) should be selected for the rotor and casing.

- Daily maintenance: Regularly check the wear condition of the screw rotors and stator; if there is excessive wear, replace them in time to avoid reducing the pump’s efficiency and causing oil leakage.

6.Advantages Compared with Other Oil Transfer Pumps

- Compared with gear oil transfer pumps: Screw pumps have lower noise, wider viscosity adaptation range, and are less prone to jamming when conveying oil with impurities.

- Compared with centrifugal oil transfer pumps: Screw pumps have stronger self-priming capacity and higher pressure resistance, and the flow rate is more stable under variable working conditions.

Key Selection Considerations for Oil transfer pump.

When selecting an oil transfer pump, it is necessary to consider the properties of the fluid to be transferred—such as viscosity, corrosiveness, and temperature—as well as requirements for flow rate and pressure, and the operating environment. This ensures that the pump’s performance and reliability meet the actual application needs.