Hopper Progressive Cavity Pump in Bearing Block

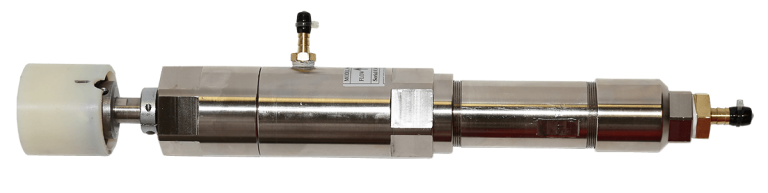

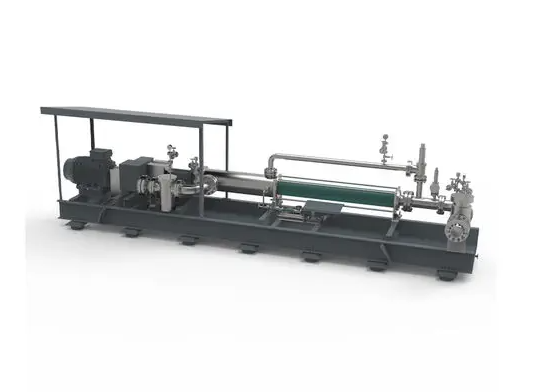

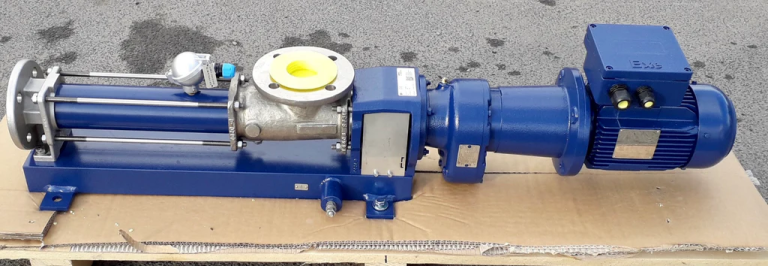

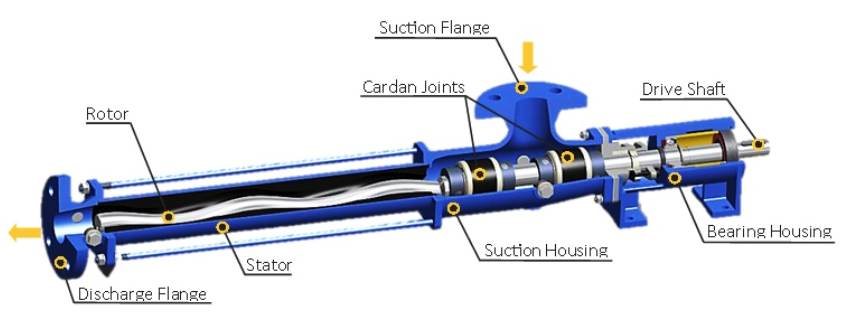

What is a Open hopper feed progressive cavity pump in bearing block design

Open hopper feed progressive cavity pump in bearing block design is a kind of progressive cavity pump which also has a enlarged rectangular hopper, coupling rod with auger and force-feed chamber with taper.

Because it is a bearing block design, it can cooperate with a variety of drivers. Its structure is stable and can bear more pressure and torsion.

[video_lightbox_youtube video_id=”JWkoODah0vY&rel=0″ width=”640″ height=”480″ alt=”Sludge Screw Pump” anchor=”https://pumpvv.com/wp-content/uploads/2023/03/pump-cover1.png”]

The Features of Open hopper feed progressive cavity pump

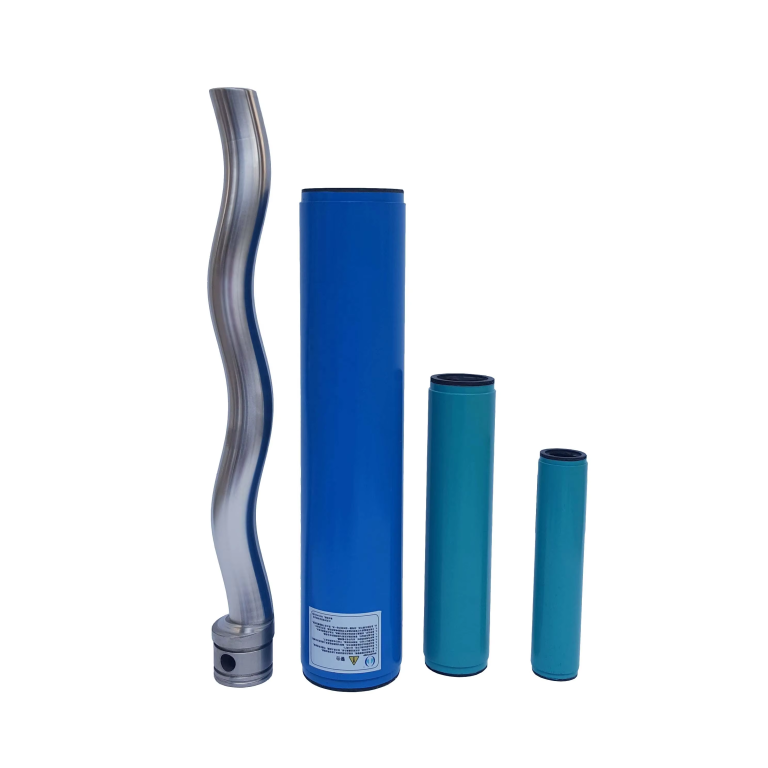

- Open hopper cavity pump larger hopper, larger capacity

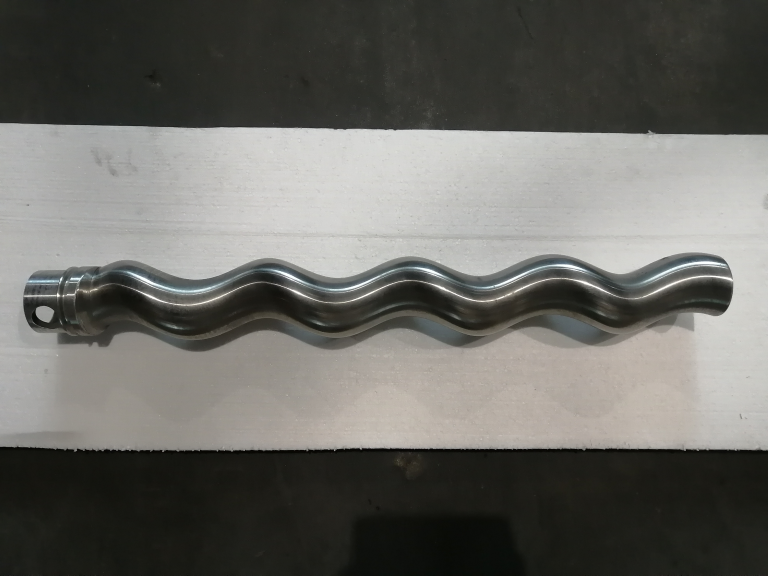

- Special coupling rod with auger has greater torque and stronger propulsion

- The large force-feed chamber with taper is more conducive to the transportation of materials

- Bearing block design, more diverse driving methods

- The structure is stable and can withstand worse working conditions

- Easy to disassemble and maintain

- Continuous low pulsation transportation, not affected by pressure and viscosity

- It can transport media with higher viscosity and poor fluidity

- High efficiency and long life

- Stator with hopper-shaped entrance for optimal filling of the conveying chamber

- Reinforced screw

The open hopper feed progressive cavity pump parameter table

| Pump Type | Pressure Range (bar) | Capacity Range (m³/h) | Speed Range (rpm) | Inlet Size (G/DN) | Outlet Size (G/DN) | Motor Power (KW) |

|---|---|---|---|---|---|---|

| MJN025-2S | 0~12 | 0~0.25 | 0~350 | G1¼ | G1¼ | 0.37 |

| MJN05-1L | 0~6 | 0~0.5 | 0~350 | G1¼ | G1¼ | 0.37 |

| MJN05-2S | 0~12 | 0~0.5 | 0~350 | G1¼ | G1¼ | 0.75 |

| MJN1-1L | 0~6 | 0~1 | 0~350 | G1¼ | G1¼ | 0.75 |

| MJN1-2S | 0~12 | 0~1 | 0~350 | 50 | 50 | 1.5 |

| MJN1-4S | 0~24 | 0~0.5 | 0~250 | 50 | 50 | 3 |

| MJN3-1L | 0~6 | 0~3 | 0~350 | 50 | 50 | 2.2 |

| MJN3-2S | 0~12 | 0~2.5 | 0~350 | 65 | 65 | 3 |

| MJN3-4S | 0~24 | 0~1.5 | 0~250 | 65 | 65 | 5.5 |

| MJN5-1L | 0~6 | 0~5 | 0~320 | 65 | 65 | 3 |

| MJN5-2S | 0~12 | 0~5 | 0~320 | 80 | 80 | 4 |

| MJN5-3S | 0~18 | 0~3 | 0~250 | 80 | 80 | 5.5 |

| MJN5-4S | 0~24 | 0~2 | 0~200 | 80 | 80 | 7.5 |

| MJN10-1L | 0~6 | 0~10 | 0~300 | 80 | 80 | 4 |

| MJN10-2S | 0~12 | 0~7 | 0~300 | 80 | 80 | 5.5 |

| MJN10-3S | 0~18 | 0~6 | 0~250 | 80 | 80 | 7.5 |

| MJN10-4S | 0~24 | 0~4 | 0~200 | 80 | 80 | 11 |

| MJN15-1L | 0~6 | 0~15 | 0~300 | 80 | 80 | 5.5 |

| MJN15-2S | 0~12 | 0~12 | 0~300 | 100 | 100 | 7.5 |

| MJN15-3S | 0~18 | 0~10 | 0~250 | 100 | 100 | 11 |

| MJN15-4S | 0~24 | 0~7 | 0~200 | 100 | 100 | 15 |

| MJN25-1L | 0~6 | 0~25 | 0~280 | 100 | 100 | 7.5 |

| MJN25-2S | 0~12 | 0~22 | 0~300 | 125 | 125 | 11 |

| MJN25-3S | 0~18 | 0~15 | 0~250 | 125 | 125 | 15 |

| MJN25-4S | 0~24 | 0~12 | 0~200 | 125 | 125 | 18.5 |

| MJN50-1L | 0~6 | 0~50 | 0~280 | 125 | 125 | 11 |

| MJN50-2S | 0~12 | 0~35 | 0~250 | 150 | 150 | 22 |

| MJN50-3S | 0~18 | 0~30 | 0~230 | 150 | 150 | 30 |

| MJN50-4S | 0~24 | 0~26 | 0~200 | 150 | 150 | 37 |

| MJN80-1L | 0~6 | 0~80 | 0~280 | 150 | 150 | 22 |

| MJN80-2S | 0~12 | 0~60 | 0~280 | 150 | 150 | 37 |

| MJN80-3S | 0~18 | 0~42 | 0~200 | 150 | 150 | 45 |

| MJN80-4S | 0~24 | 0~25 | 0~150 | 150 | 150 | 55 |

| MJN120-1L | 0~6 | 0~120 | 0~250 | 150 | 150 | 37 |

| MJN120-2S | 0~12 | 0~100 | 0~270 | 200 | 200 | 45 |

| MJN120-3S | 0~18 | 0~60 | 0~180 | 200 | 200 | 55 |

| MJN120-4S | 0~24 | 0~50 | 0~150 | 200 | 200 | 55 |

| MJN180-1L | 0~6 | 0~180 | 0~220 | 200 | 200 | 45 |

| MJN180-2S | 0~12 | 0~170 | 0~220 | 200 | 200 | 55 |

| MJN300-1L | 0~6 | 0~300 | 0~220 | 200 | 200 | 55 |

The Applications of Open hopper feed progressive cavity pump

Generally used for high viscosity, dense or fluffy media without bridging phenomenon in environmental protection, food and chemical industries;

It is especially suitable for continuous and low-pulse transportation of fermented renewable raw materials, liquid fertilizers, process water, ground biological waste, food waste, pre-processed slaughterhouse waste, concentrated substrate, thickened substrate and sludge.

People Also Ask

Send Your Enquiry :