[wpseo_breadcrumb]

Design features: precise and efficient stator structure

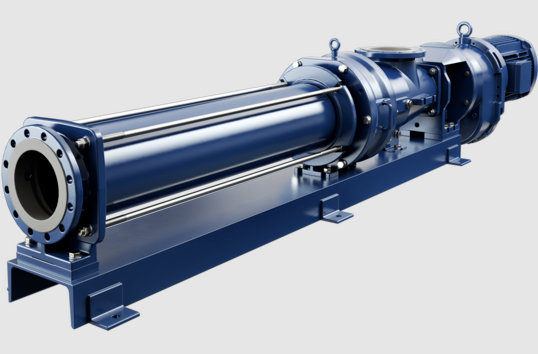

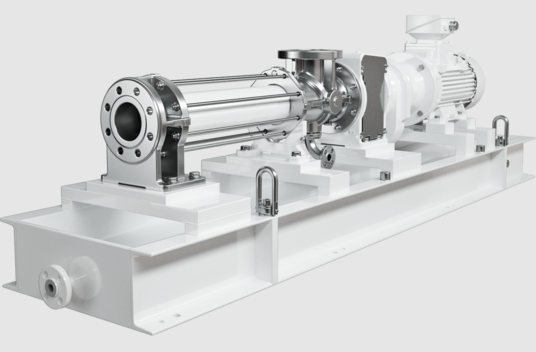

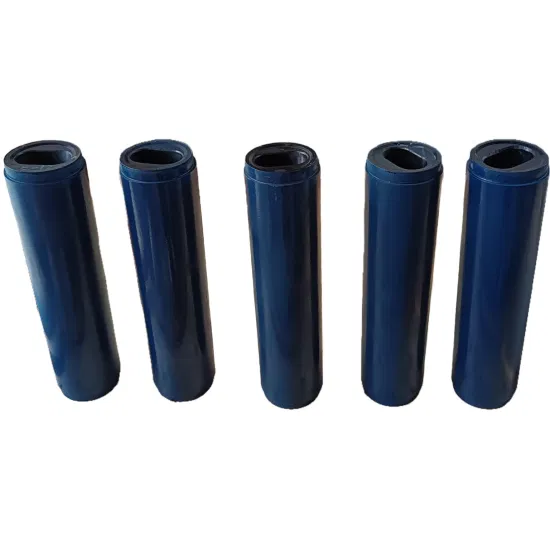

The seepex BN100-12L stator adopts a carefully designed structure, which reflects excellent craftsmanship in terms of flow channel shape, material selection and manufacturing process.

The inner wall of the stator adopts a special spiral flow channel design, which can provide a smooth flow channel for the fluid and minimize turbulence and energy loss. This optimized flow channel design not only improves the conveying efficiency of the stator, but also greatly reduces mechanical losses, laying the foundation for the improvement of the performance of the whole machine.

The stator is made of high-quality wear-resistant and corrosion-resistant materials, which is not only reliable and corrosion-resistant, but also has excellent wear resistance. Even in harsh working environments, the stator can maintain a good operating state, greatly extending the service life of the equipment.

The precise manufacturing process ensures the high consistency of the stator structure and the precise coordination between the rotor and the stator during operation, thereby improving the efficiency and reliability of the whole machine.

Application areas: widely applicable stator solutions

With excellent performance indicators, seepex BN100-12L stator is widely used in various industrial fields:

Chemical industry: handling the transportation of various chemicals, solvents and other corrosive substances

Food industry: conveying viscous food raw materials, such as syrups, sauces, etc.

Environmental protection industry: handling sludge, sludge and other media containing particulate matter

Building materials industry: conveying cement, mortar and other materials that are easy to clog

Mining industry: conveying high-viscosity media such as mineral slurry and coal slime

Technical characteristics: advanced performance

seepex BN100-12L stator has outstanding performance, which is mainly reflected in the following aspects:

Wear and corrosion resistance: The rubber material has been specially treated to have excellent wear resistance and corrosion resistance, which greatly extends the service life

Smooth conveying: The spiral shape ensures smooth fluid conveying, reduces pulsation and noise

High temperature adaptability: It can operate stably in a wide temperature range to meet the requirements of different working conditions

Easy maintenance: Humanized design, convenient and quick daily maintenance and maintenance

Product advantages: Stator solution with excellent performance

Through advanced design concepts and exquisite manufacturing processes, seepex BN100-12L stator shows outstanding advantages in many aspects:

Optimized flow channel design: The spiral inner wall flow channel ensures the excellent performance of the stator in efficiently conveying fluids.

Excellent corrosion resistance and wear resistance: Made of high-quality materials, it can reliably resist corrosion and wear in harsh environments and extend the service life of the equipment.

Simple and easy-to-maintain structure: The compact design is easy to disassemble and assemble, reducing maintenance costs and downtime.

Wide range of applications: Applicable to multiple fields such as industry, chemical industry, environmental protection, etc., to meet the needs of various fluid conveying.

Ending

With the above advantages, the seepex BN100-12L stator can not only improve the performance and efficiency of the equipment, but also minimize the operation and maintenance costs, creating greater value for users.

people also ask

Send Your Enquiry :