Parameters

- Voltage: 380V

- Pump shaft position: horizontal

- Material: cast steel

- Working pressure: 1.2MPa

- Flow rate: 35m³/h

- Drive mode: electric

- Scope of application: sewage sludge

- Transport medium: sewage pump, impurity pump

- Model: BN100-12

- Performance: high pressure

- Lift: 120m

- Impeller structure: single impeller

- Impeller suction mode: single suction

- Weight: 220kg

- Speed: 220RPM

- Application: sewage pump

- Pressure: 1.2Mpa

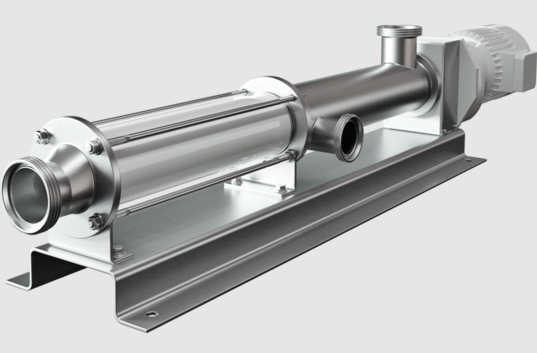

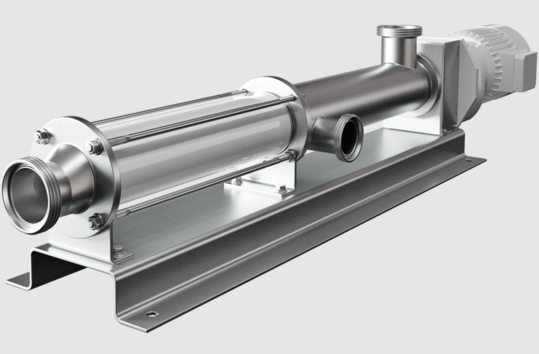

- Brand: SEEPEX

Design features

seepex BN100-12L adopts a unique design concept, making full use of the structural characteristics of the screw pump, while ensuring stability and durability, taking into account flexibility and versatility. Its unique BN100-12L rotor and BN100-12L stator structure can ensure stable and efficient delivery of liquid media of various viscosities under various working conditions, and has a wide range of applications.

- The precision processing and matching of the screw and rotor ensure excellent sealing performance, reduce leakage and energy consumption.

- The selection of anti-corrosion and wear-resistant materials ensures the service life of the equipment.

- The compact structural design reduces the footprint and is easy to install and maintain.

- Advanced bearing and sealing technology improves the reliability of the equipment.

Technical features

seepex BN100-12L is developed based on advanced screw pump technology, and has been carefully optimized in terms of structural design, material selection, process manufacturing and other aspects, ensuring its outstanding performance in terms of working performance, service life, energy consumption control and other aspects.

Its unique rotor and stator structure not only ensures the smoothness and efficiency of the conveying process, but also ensures low vibration and low noise during the operation of the pump. In addition, this pump type adopts a variety of sealing system designs, which greatly improves the reliability and safety of use.

| Wide flow range, can meet various working conditions. |

| High outlet pressure, up to 15bar, suitable for various pipeline conditions. |

| Excellent self-priming performance, can handle gas-containing fluids. |

| Low noise and vibration ensure the quiet operation of the equipment. |

| Reversible steering to meet different process requirements. |

Application areas

With excellent performance and wide applicability, seepex BN100-12L is widely used in industrial production, public utilities, chemicals, food, pharmaceuticals and many other fields.

Whether it is the transportation of high-viscosity materials or occasions with special requirements for hygiene and sterility, this pump type can perfectly meet the needs, fully demonstrating its powerful functional advantages.

- Chemical industry: conveying various corrosive, viscous, and easy-to-crystallize chemicals.

- Environmental protection industry: handling sludge, sewage and other fluids containing solid particles.

- Pharmaceutical industry: conveying sterile and pollution-free pharmaceutical raw materials and preparations.

- Food industry: conveying high-viscosity materials such as jam, honey, and chocolate.

- Mining industry: conveying solid-containing fluids such as slurry and mud.

Product advantages

Compared with similar pump products, seepex BN100-12L brings many unique advantages to users with its excellent design concept and excellent performance:

Wide range of applications, can meet various working conditions and liquid transportation needs

Reasonable structural design, stable and reliable operation, easy maintenance

Excellent material selection, strong corrosion resistance, long service life

Energy saving and environmental protection, high energy efficiency, low operating cost

These outstanding features make seepex BN100-12L stand out among similar pump products. Whether in industrial production or public utilities, this pump type can provide stable, reliable, efficient and energy-saving liquid transportation solutions, creating significant economic and social value for users.

people also ask

Send Your Enquiry :