[wpseo_breadcrumb]

Introduction

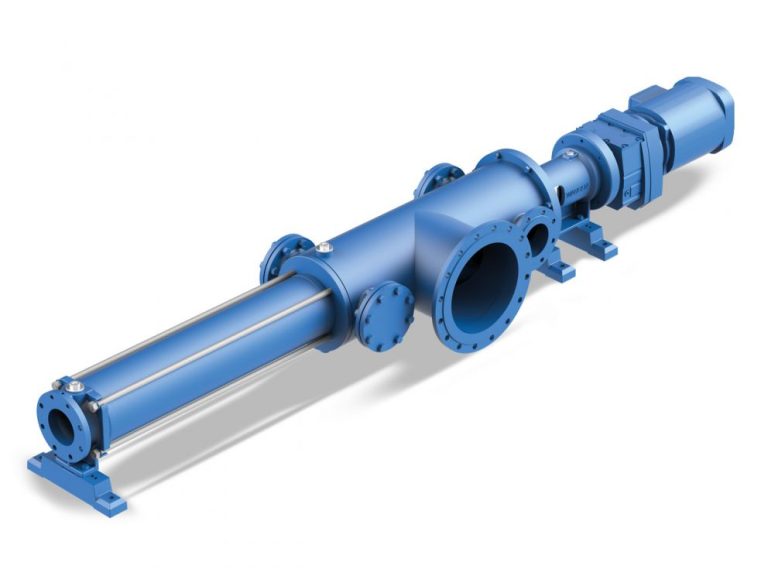

The hydraulic progressive cavity pump is a specialized type of positive displacement pump widely used in various industries. Its unique design allows for the efficient transfer of viscous fluids, making it an essential tool in applications ranging from wastewater treatment to oil and gas extraction.

How It Works

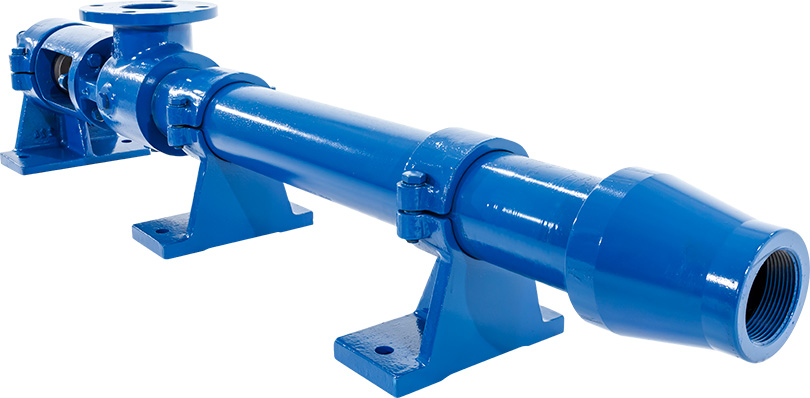

The hydraulic progressive cavity pump operates on a simple yet effective principle. It consists of a helical rotor that rotates within a stator, creating cavities that progressively move the fluid through the pump. This mechanism allows for a smooth and continuous flow, minimizing pulsation and ensuring consistent output.

Key Components

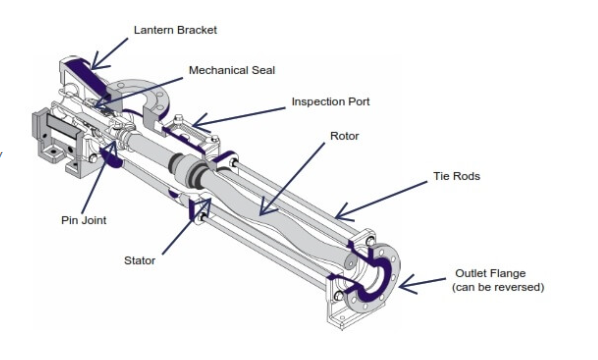

- Helical Rotor: The rotor is the key component that creates the cavities. Its design allows it to efficiently move fluids with varying viscosities.

- Stator: The stator surrounds the rotor and is typically made of elastomeric materials. It plays a crucial role in sealing the cavities formed by the rotor.

- Drive System: The pump is usually powered by an electric motor or hydraulic system, providing the necessary torque to rotate the rotor.

- Inlet and Outlet Ports: These ports facilitate the entry and exit of the fluid, ensuring a seamless process.

Applications

Hydraulic progressive cavity pumps are versatile and can be found in numerous applications, including:

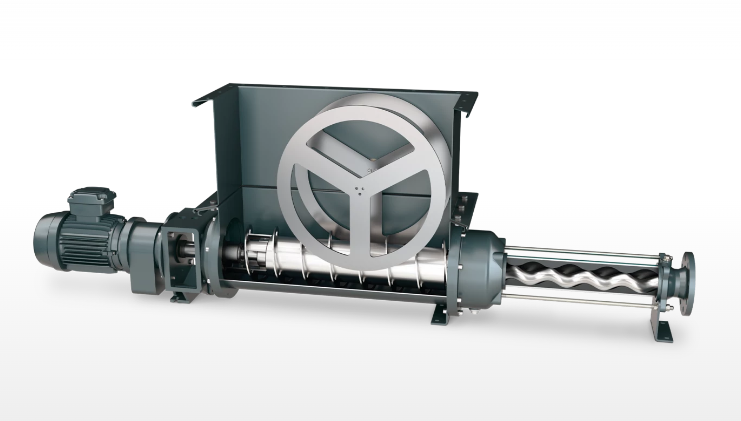

- Wastewater Treatment: They are effective in handling sludge and other viscous waste materials.

- Food and Beverage Industry: These pumps are suitable for transferring thick products like sauces and syrups without damaging them.

- Oil and Gas: In this sector, they are used for enhanced oil recovery and transporting crude oil.

- Chemical Processing: Their ability to handle corrosive and abrasive fluids makes them ideal for various chemical applications.

Advantages

The hydraulic progressive cavity pump offers several advantages that make it a preferred choice in many industries:

- Versatility: Capable of handling a wide range of fluid viscosities and compositions.

- Gentle Handling: The progressive cavity design minimizes shear stress, preserving the integrity of sensitive fluids.

- Self-Priming: These pumps can self-prime, making them suitable for applications where suction lift is required.

- Low Maintenance: With fewer moving parts compared to other pump types, maintenance requirements are typically lower.

Conclusion

In summary, the hydraulic progressive cavity pump is a vital component in various industrial applications. Its efficient design, versatility, and ability to handle viscous and sensitive fluids make it an invaluable asset. As industries continue to evolve, the demand for such specialized pumps will likely grow, further emphasizing their importance in modern fluid transfer processes.

People also ask

Send Your Enquiry :