[wpseo_breadcrumb]

Introduction

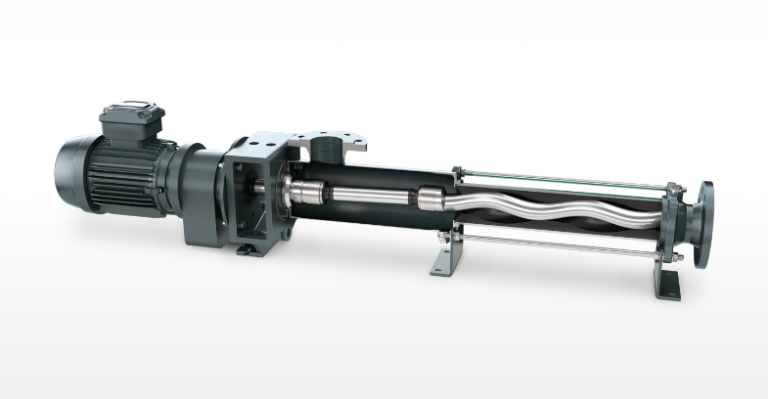

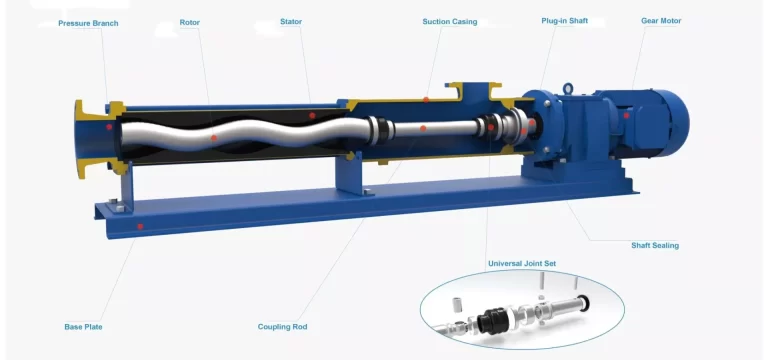

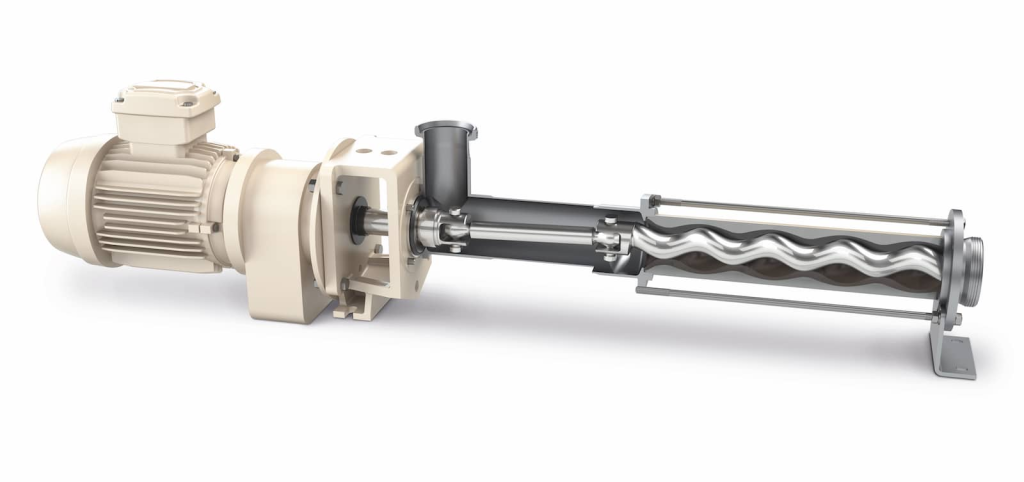

Hygienic progressing cavity pumps are essential in various industries, particularly where cleanliness and product integrity are paramount. These pumps are designed to handle viscous fluids and slurries while ensuring minimal contamination. Their unique design and operation make them ideal for applications in food and beverage, pharmaceuticals, and biotechnology.

Features of Hygienic Progressing Cavity Pumps

- Design and Construction

- Made from high-quality stainless steel, these pumps are resistant to corrosion and easy to clean.

- The smooth surfaces minimize the risk of bacterial growth, adhering to stringent hygiene standards.

- Gentle Handling of Products

- The progressing cavity mechanism allows for a smooth and continuous flow, reducing shear stress on sensitive products.

- This is particularly important for handling delicate substances such as yogurt, creams, and certain pharmaceutical compounds.

- Versatile Applications

- Suitable for a wide range of products, including viscous liquids, slurries, and shear-sensitive materials.

- Commonly used in industries like food processing, dairy, pharmaceuticals, and cosmetics.

Advantages of Hygienic Progressing Cavity Pumps

- Efficient Operation

- They provide consistent flow rates and can handle varying viscosities with ease.

- Easy Maintenance

- The design facilitates quick disassembly and cleaning, essential for maintaining hygiene standards.

- Reduced Contamination Risk

- The closed design minimizes exposure to the environment, reducing the risk of contamination.

Applications

Hygienic progressing cavity pumps are widely used in various applications, including:

- Food and Beverage Industry

- Transporting sauces, syrups, and dairy products while maintaining product quality and safety.

- Pharmaceutical Manufacturing

- Moving sensitive liquids and compounds that require strict hygiene controls to prevent contamination.

- Cosmetic Production

- Handling creams and lotions without compromising their integrity.

Conclusion

Hygienic progressing cavity pumps are a vital component in industries where hygiene and product integrity are critical. Their unique features allow them to handle a variety of applications while ensuring compliance with health and safety regulations. As industries continue to prioritize quality and safety, these pumps will remain an essential tool for efficient and hygienic operations.

People also ask

Send Your Enquiry :