[wpseo_breadcrumb]

Introduction

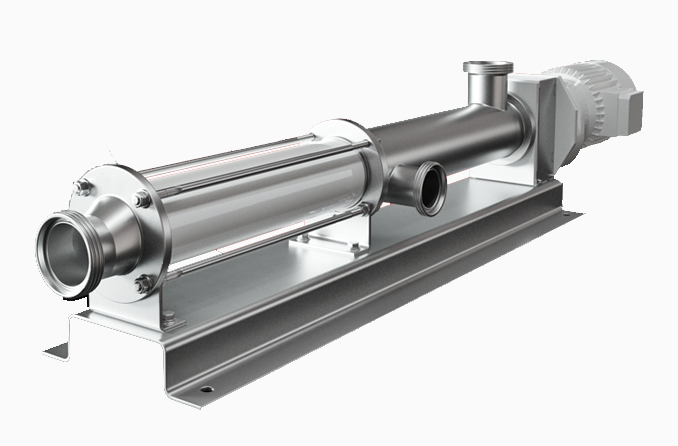

In the world of fluid transfer, hygienic progressive cavity pumps play a crucial role, particularly in industries that demand high standards of cleanliness and efficiency. These pumps are designed to handle a variety of fluids, including viscous, shear-sensitive, and abrasive materials. Their unique construction and operational principles make them ideal for applications in the food, pharmaceutical, and biotechnology sectors.

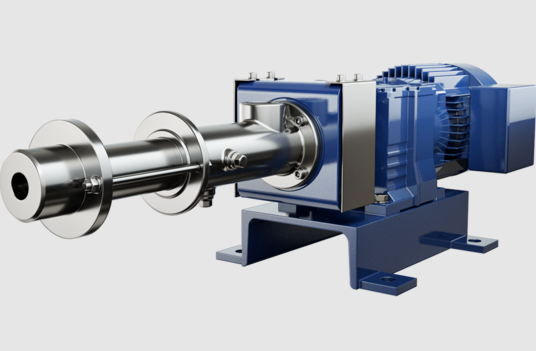

How Progressive Cavity Pumps Work

Progressive cavity pumps operate using a helical rotor that rotates within a stator. This configuration creates a series of cavities that move the fluid from the inlet to the outlet. The smooth and continuous flow produced by this design minimizes turbulence, making these pumps suitable for delicate substances.

Key Components

- Rotor: The rotating element that moves the fluid.

- Stator: The stationary part that creates the cavities for fluid transport.

- Drive Mechanism: Often an electric motor that provides the necessary rotational force.

- Seals: Essential for preventing leaks and maintaining hygiene standards.

Advantages of Hygienic Progressive Cavity Pumps

Hygienic progressive cavity pumps offer several benefits that make them particularly valuable in sensitive applications:

- Sanitary Design: These pumps are constructed from materials that comply with health regulations, ensuring that they do not contaminate the fluids they handle.

- Versatility: They can handle a wide range of fluid types, including those that are thick, abrasive, or contain solids.

- Gentle Handling: The design minimizes shear forces, making them ideal for sensitive materials that could be damaged by conventional pumping methods.

- Self-Priming Ability: Many models can operate without the need for additional priming, which enhances efficiency and reduces downtime.

- Low Pulsation: The continuous flow characteristic results in low pulsation, making them suitable for processes requiring steady flow rates.

Applications

These pumps are utilized in various industries where hygiene and precision are paramount:

- Food and Beverage: Handling products like sauces, dairy, and juices.

- Pharmaceuticals: Moving active ingredients and formulations that require careful handling.

- Cosmetics: Transferring creams and lotions without compromising their quality.

- Biotechnology: Managing sensitive biological materials during production processes.

Maintenance Considerations

To ensure optimal performance and longevity, regular maintenance is essential:

- Inspection: Routinely check seals and gaskets for wear and tear.

- Cleaning: Implement a thorough cleaning regimen to prevent contamination.

- Lubrication: Keep moving parts well-lubricated to reduce wear.

- Monitoring: Regularly monitor performance metrics to catch potential issues early.

Conclusion

Hygienic progressive cavity pumps are indispensable tools in industries where cleanliness and fluid integrity are crucial. Their unique design and operational capabilities not only enhance efficiency but also ensure compliance with stringent hygiene standards. By understanding their advantages, applications, and maintenance needs, industries can leverage these pumps to improve their processes and product quality.

People also ask

Send Your Enquiry :