[wpseo_breadcrumb]

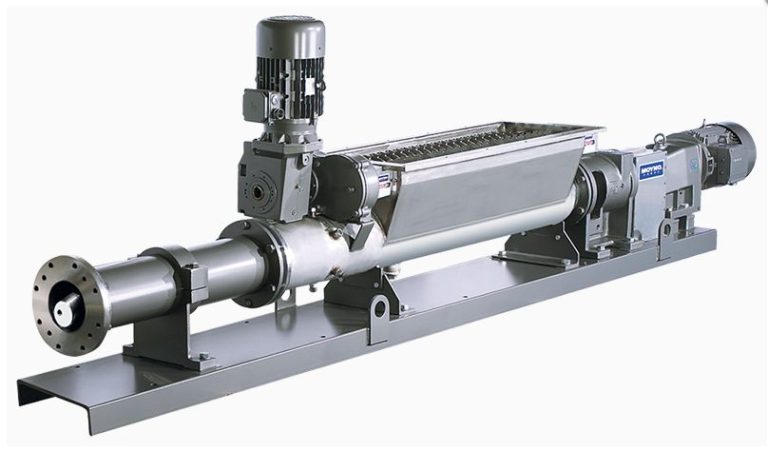

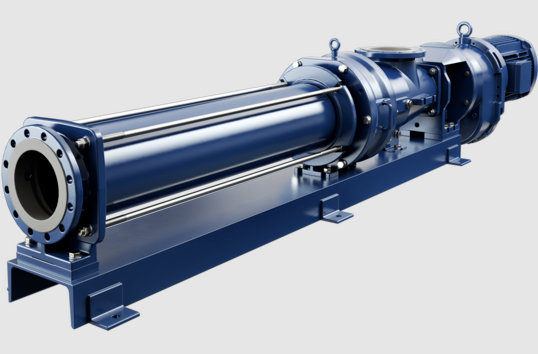

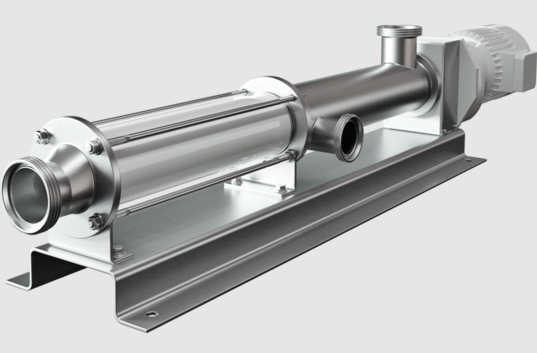

Progressive cavity pumps have become an integral part of various industries in China. Known for their unique design and operational efficiency, these pumps are widely used for transporting fluids with varying viscosity levels. This article explores the features, advantages, applications, and future trends of progressive cavity pumps in China.

Features of Progressive Cavity Pumps

Progressive cavity pumps are characterized by their helical rotor and stator design. This design allows for the smooth transfer of fluids, making them suitable for a range of applications. Key features include:

- Versatile Fluid Handling: They can handle a variety of fluids, from thin liquids to thick sludges.

- Constant Flow Rate: These pumps provide a steady flow regardless of pressure changes, ensuring consistent performance.

- Self-Priming Capability: They can easily draw fluid into the pump without needing external assistance.

- Durable Construction: Made from high-quality materials, progressive cavity pumps are built to withstand harsh operating conditions.

Advantages of Using Progressive Cavity Pumps

The benefits of using progressive cavity pumps are numerous, making them a popular choice in many sectors. Some key advantages include:

- Efficiency: Their design minimizes energy consumption, making them cost-effective over time.

- Low Maintenance: With fewer moving parts, these pumps require less maintenance compared to other pump types.

- Flexibility: They can be used in various applications, from wastewater treatment to food processing.

- Reliable Performance: Progressive cavity pumps are known for their reliability, which is crucial in industries that require continuous operation.

Applications in Various Industries

Progressive cavity pumps are utilized across multiple sectors in China. Some common applications include:

- Oil and Gas: Used for transporting crude oil and other viscous fluids.

- Food and Beverage: Ideal for moving food products, including pastes and slurries.

- Chemical Processing: Suitable for handling chemicals, including corrosive substances.

- Wastewater Treatment: Effective in pumping sludge and other wastewater materials.

Future Trends in the Industry

The demand for progressive cavity pumps in China is expected to grow, driven by advancements in technology and increasing industrialization. Some emerging trends include:

- Automation: The integration of smart technologies for monitoring and control is becoming more prevalent.

- Sustainability: There is a growing emphasis on environmentally friendly designs and materials.

- Customization: Manufacturers are focusing on producing pumps tailored to specific industry needs.

Conclusion

China’s progressive cavity pump industry is poised for significant growth, driven by its versatility and efficiency. As industries continue to evolve, these pumps will play a crucial role in meeting the demands of modern applications. With ongoing advancements in technology and a focus on sustainability, the future of progressive cavity pumps looks promising.

Fill up and submit the below inquiry form, or directly write us an email: info@pumpvv.com