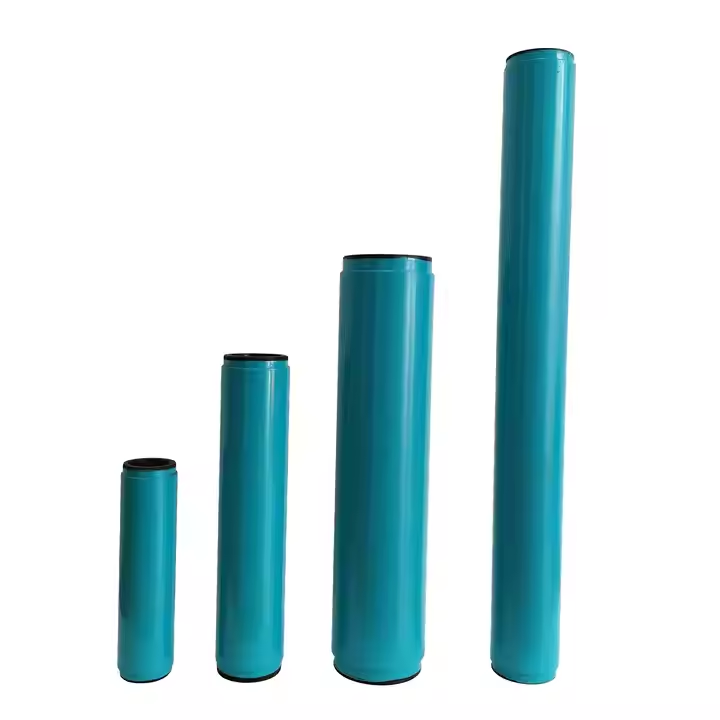

Characteristics of the BN15-6L Stator

1. High Efficiency

The BN15-6L stator utilizes advanced materials and design, enabling it to maintain high efficiency under various working conditions. Its structure is meticulously designed to ensure smooth fluid flow, thereby reducing energy loss.

2. Wear Resistance

This stator boasts excellent wear resistance, capable of withstanding prolonged use without damage. This makes it particularly effective in handling viscous and abrasive fluids, ultimately lowering maintenance costs.

3. Easy Installation

The BN15-6L stator is designed with user convenience in mind, allowing for simple and quick installation. Even in complex industrial environments, replacement and installation can be completed rapidly, minimizing downtime.

4. Variety of Material Options

Depending on specific application requirements, the BN15-6L stator offers a range of material options. This allows users to choose the most suitable material based on the working environment and fluid characteristics, achieving optimal performance.

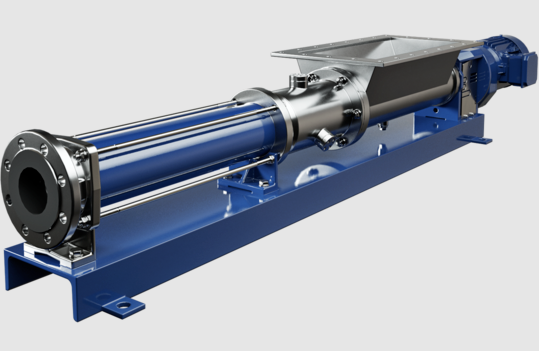

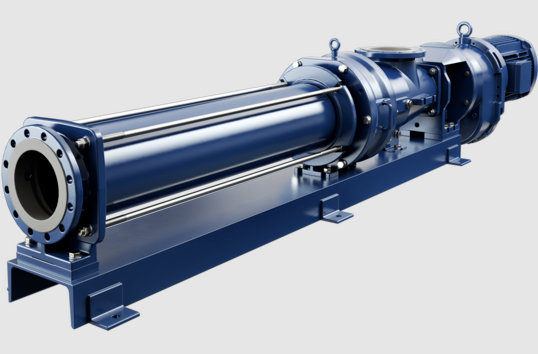

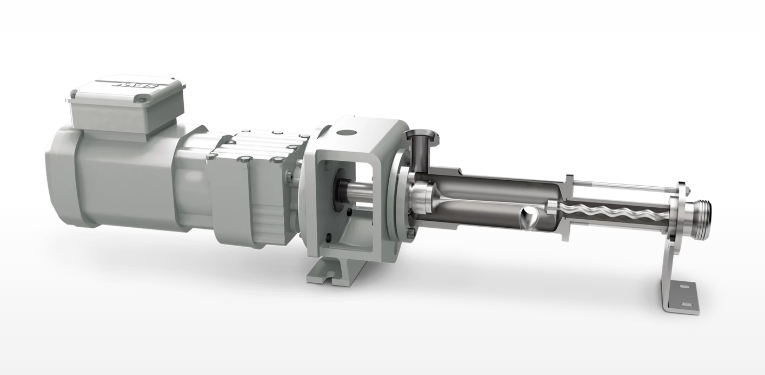

Working Principle

The working principle of the BN15-6L stator is closely linked to the operation of the screw pump. As the rotor of the pump rotates, a sealed space is formed within the stator, allowing liquid to be efficiently drawn in and pushed through the helical passage. Due to the precise fit between the stator and rotor, fluid flow is continuous and smooth, reducing pulsation and noise.

This design enables the BN15-6L stator to handle fluids of varying viscosities, from low-viscosity liquids to high-viscosity slurries. Additionally, the stator operates effectively across a wide temperature range, meeting diverse industrial requirements.

Applications of the BN15-6L Stator

- 1. Chemical Industry

In the chemical industry, the properties of fluids can vary greatly. The efficiency and wear resistance of the BN15-6L stator make it an ideal choice for this sector, capable of handling various types of chemicals and ensuring smooth production processes.

- 2. Food Processing

The food processing industry has stringent hygiene and safety requirements. The BN15-6L stator is made from food-safe materials, ensuring that no contamination occurs during fluid transport, thus safeguarding food safety.

- 3. Oil and Gas

In the extraction and transportation of oil and gas, fluid viscosity and corrosiveness are major considerations. The wear and corrosion resistance of the BN15-6L stator makes it widely applicable in this field.

- 4. Water Treatment

In the water treatment industry, the removal of pollutants and the enhancement of water quality are core tasks. The BN15-6L stator can effectively handle various wastewater fluids, aiding in the purification process.

Maintenance and Care for the BN15-6L Stator

To ensure the long-term stable operation of the BN15-6L stator, regular maintenance and care are crucial. Here are some recommendations:

1. Regular Inspections

Conduct regular inspections of the stator for wear and tear. Timely detection of issues can significantly extend its service life. Pay attention to seals and connection points to ensure there are no leaks.

2. Cleaning Maintenance

Regularly clean both the interior and exterior of the stator to prevent the accumulation of dirt and debris. Use appropriate cleaning agents, avoiding highly corrosive chemicals.

3. Lubrication

Follow the user manual to periodically lubricate the stator’s moving parts, ensuring smooth operation. Proper lubrication can reduce friction and enhance efficiency.

4. Timely Replacement

If significant wear or damage is observed, replace the stator promptly. Delaying replacement can lead to greater losses and higher repair costs.

people also ask

Fill up and submit the below inquiry form, or directly write us an email: info@pumpvv.com