1. Performance Advantages

1.1 High Efficiency

The seepex BN15-6L is recognized for its remarkable pumping efficiency. Compared to traditional centrifugal pumps, the BN15-6L operates with higher efficiency when handling high-viscosity liquids. This capability enables it to reduce energy consumption in continuous operation environments, ultimately saving operational costs for businesses.

1.2 Stability and Reliability

In industrial applications, the stability and reliability of pumps are essential. The BN15-6L utilizes advanced technology to maintain excellent performance even during prolonged operation. Its high wear resistance and corrosion resistance allow the pump to function properly in harsh environments, decreasing maintenance frequency.

1.3 Versatile Applications

The BN15-6L is not only suitable for the chemical and food industries but also finds applications in wastewater treatment, oil, and pharmaceuticals. Its versatility allows users to adjust the pump’s parameters according to varying needs, meeting diverse process requirements.

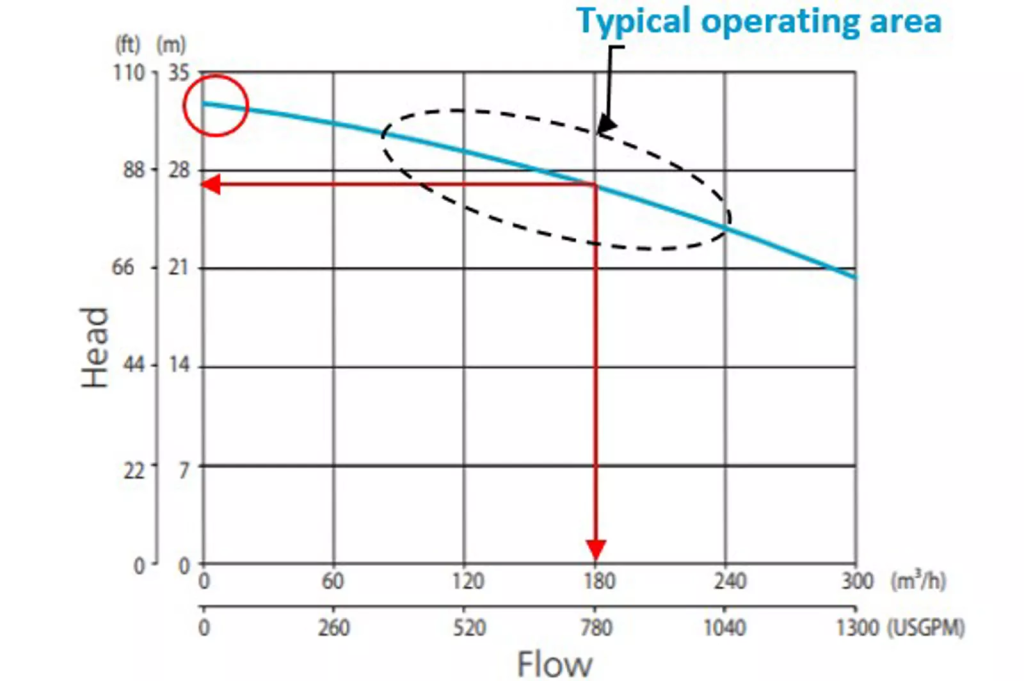

Parameters

| Brand:seepex | Speed:279(rpm) | Power:3kW |

| Drive mode:Electric | Suction port:DN80(mm) | Suction head:10m |

| Performance:Wear-resistant | Discharge port:DN80(mm) | Shaft power:3 |

| Number of impellers:Single stage | Efficiency:98% | Operating temperature:Normal temperature |

| Flow rate:3.1-16.4(m3/h) | Output flow rate:200 | Material:Stainless steel |

| Head:60m | Weight:80kg | Model:BN15-6L |

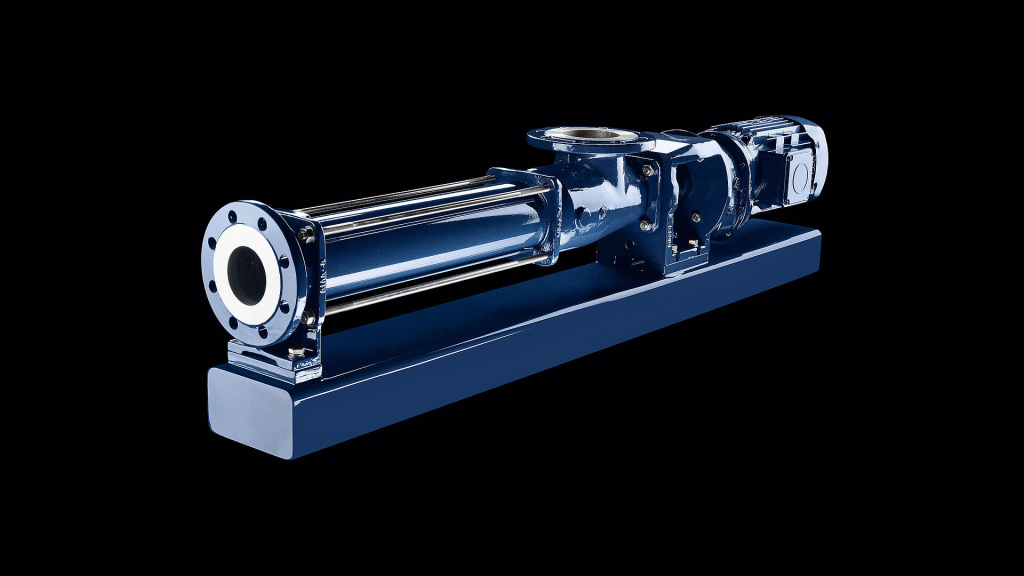

The BN15-6L rotor is crafted from advanced materials and precision manufacturing processes, ensuring reliability and durability in diverse environments. The design typically features multiple helical blades, which facilitate the movement of the medium through a screw-like action.

The BN15-6L stator utilizes advanced materials and design, enabling it to maintain high efficiency under various working conditions. Its structure is meticulously designed to ensure smooth fluid flow, thereby reducing energy loss.

2. Applications of the BN15-6L

2.1 Food Industry

In food processing, the BN15-6L can safely and effectively transport various liquids, including juices, dairy products, and sauces. Its design complies with food safety standards, ensuring product hygiene and safety.

2.2 Chemical Industry

The chemical industry has high demands for pumps, and the BN15-6L, with its corrosion-resistant materials and excellent sealing performance, can handle various chemicals, ensuring safety and reliability in the production process.

2.3 Pharmaceutical Industry

In the pharmaceutical sector, the purity of liquids and the precision of transport are critical. The high efficiency and adjustable flow characteristics of the BN15-6L make it an ideal choice for pharmaceutical production.

3. Maintenance and Care of the BN15-6L

3.1 Regular Inspection

To ensure the normal operation of the BN15-6L, regular inspections are essential. Inspection items include the pump body, seals, and connecting pipes to ensure there are no leaks or wear.

3.2 Cleaning Maintenance

During use, the pump should be cleaned regularly, especially when handling food and pharmaceutical liquids. Appropriate cleaning agents should be used to avoid damaging the pump body.

3.3 Lubrication System

The BN15-6L is equipped with an efficient lubrication system that ensures proper lubrication between components. Regularly checking the condition of the lubricating oil and replacing it as needed can effectively extend the pump’s lifespan.

People also ask

Send Your Enquiry :