[wpseo_breadcrumb]

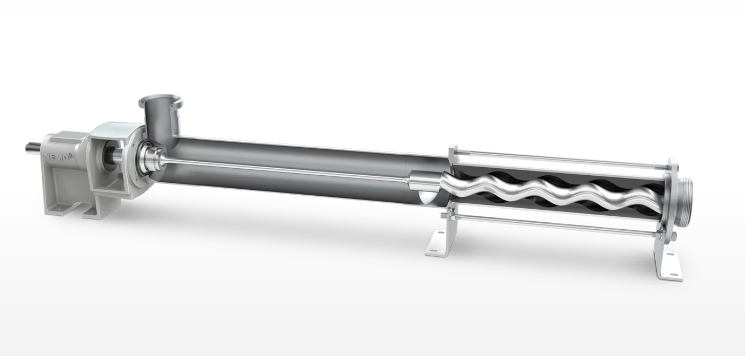

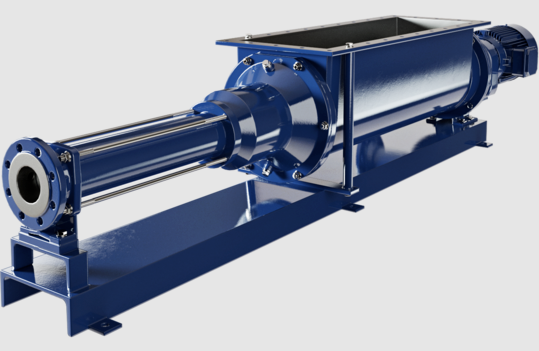

NEMO® BY Progressing Cavity Pump

The NEMO® BY block pump in industrial design can be used in environmental technology, the food and chemical industries, but also in the oil & gas upstream as well as the mid- /downstream sector for a wide variety of pressure-stable conveying or dosing tasks.

From low-viscosity media to hardly flowing products, with or without solid content, shear-sensitive, sticky or abrasive, with the NEMO® BY progressing cavity pump even difficult substances can be conveyed gently and with low pulsation, regardless of fluctuations in pressure and viscosity.

Description of NEMO® BY Progressing Cavity Pump.

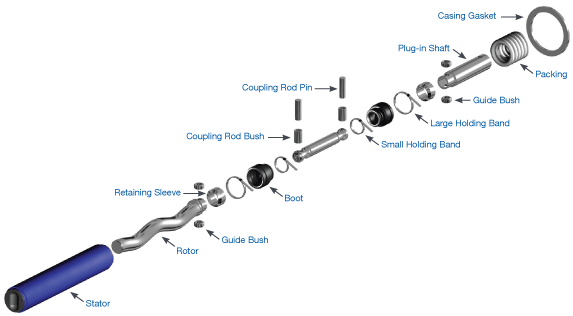

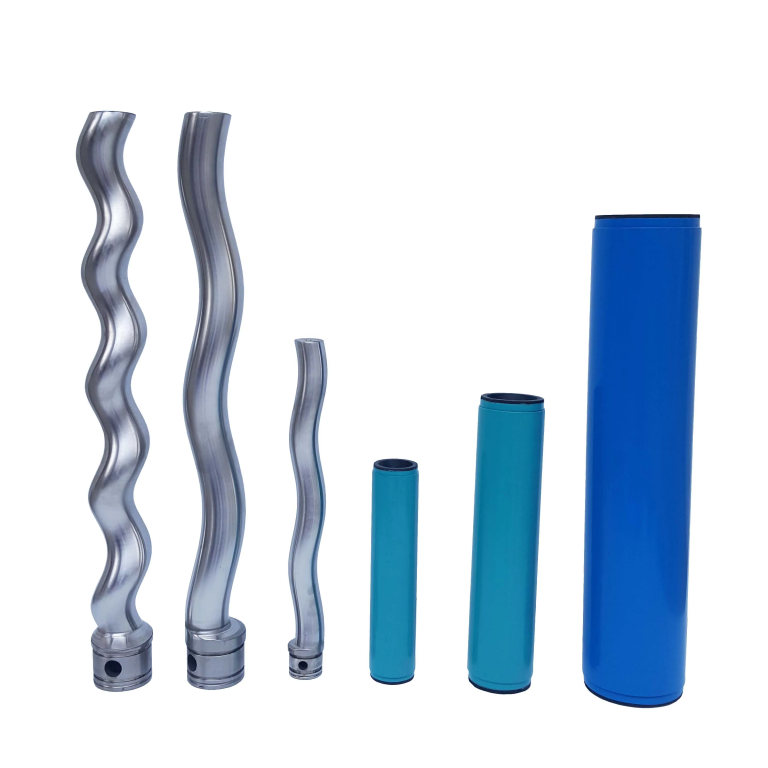

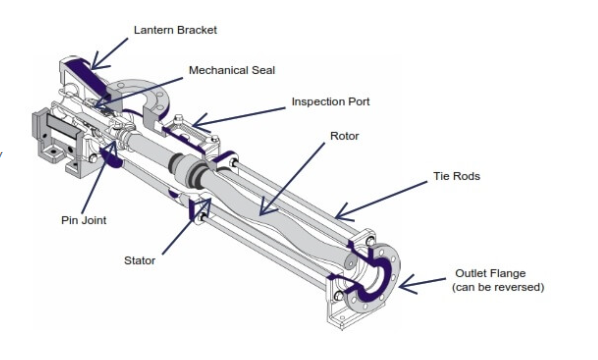

From low-viscosity media to hardly flowing products, with or without solid content, shear-sensitive, sticky or abrasive, with the NEMO® BY progressing cavity pump even difficult substances can be conveyed gently and with low pulsation, regardless of fluctuations in pressure and viscosity. In addition, the progressing cavity pump guarantees flow rates proportional to speed with high dosing accuracy over the entire speed range. In block design with flanged drive, this NEMO pump is especially compact and economical. Moreover, the NEMO® BY is distinguished by its low investment, operating and maintenance costs. Four rotor/stator geometries are available for the various products and applications.

Reliable and Versatile Pumping with the NEMO® BY Progressing Cavity Pump.

The NEMO pump is a reliable solution for numerous industrial applications. Its ability to handle low-viscosity fluids, highly viscous substances, and even those with solid content makes it an excellent choice for chemical manufacturing, food processing, wastewater treatment, and oil and gas production. Additionally, the pump’s gentle conveying and low pulsation ensure that shear-sensitive and abrasive materials can be transported without degradation or damage. Whether operating at high pressures, handling varying viscosities, or dealing with pressure fluctuations, the NEMO pump delivers consistent and accurate results with minimal maintenance and operating costs.

The features of NEMO® BY Progressing Cavity Pump

- Versatile pumping capabilities for a wide range of fluid types, including those with varying viscosities and solid content.

- Gentle conveying action with low pulsation for handling shear-sensitive and abrasive materials without degradation or damage.

- Proportional flow rates to speed with high dosing accuracy over the entire speed range.

- Block design with flanged drive for compactness and economy.

- Low investment, operating, and maintenance costs due to its efficient and reliable design.

- These features make the NEMO® BY pump an excellent choice for various industrial applications w

People Also Ask

Send Your Enquiry :