Introduction

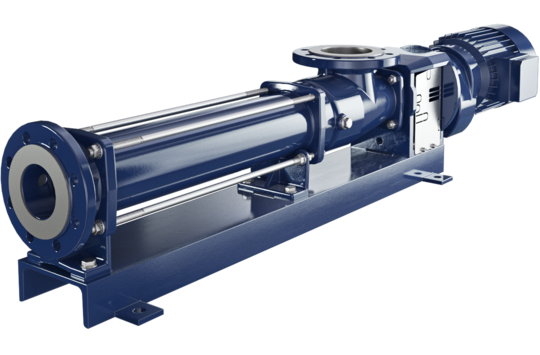

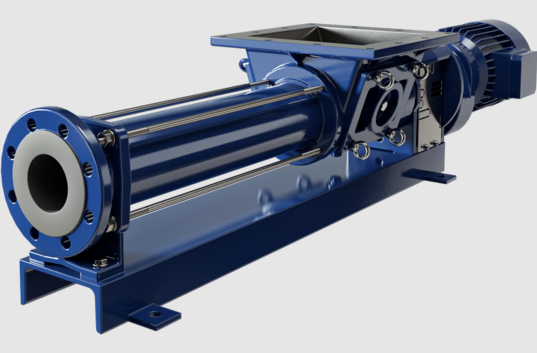

In the realm of progressive cavity pumps, the Seepex MD0005-24 Rotor stands out as a critical component designed to enhance the efficiency and performance of pumping systems. This rotor plays a vital role in the operation of progressive cavity pumps, which are widely used in various industries such as food and beverage, wastewater treatment, and chemical processing. In this article, we will explore the features, benefits, and applications of the Seepex MD0005-24 Rotor, as well as maintenance tips to ensure its longevity.

Applications of the Seepex MD0005-24 Rotor

The Seepex MD0005-24 Rotor is employed in numerous industries due to its versatility and reliability. Some common applications include:

- Food and Beverage: The rotor is used in processes such as pumping sauces, syrups, and other viscous food products, ensuring that the integrity and quality of the product are maintained.

- Wastewater Treatment: In wastewater treatment facilities, the rotor is essential for transferring sludge and other viscous materials, helping to streamline the treatment process.

- Chemical Processing: The rotor can handle a wide range of chemicals, making it suitable for use in various chemical manufacturing processes, including the transfer of polymers and other viscous liquids.

- Pharmaceuticals: In the pharmaceutical industry, the MD0005-24 Rotor is used to pump shear-sensitive products, ensuring that the active ingredients remain intact throughout the process.

Benefits of Using the Seepex MD0005-24 Rotor

Utilizing the Seepex MD0005-24 Rotor in your pumping system comes with several advantages:

- Reliability: The robust construction and quality materials used in the rotor’s design provide long-lasting performance, reducing the need for frequent replacements.

- Efficiency: The rotor’s design minimizes energy loss during operation, leading to a more cost-effective pumping solution. This efficiency is particularly beneficial in applications where energy consumption is a significant concern.

- Reduced Maintenance: The durable materials and precision engineering of the MD0005-24 Rotor contribute to lower maintenance requirements. This means reduced downtime and increased productivity for your operations.

- Adaptability: The rotor can be used in various environments and with different types of fluids, making it a flexible choice for many industrial applications.

Maintenance Tips for the Seepex MD0005-24 Rotor

To ensure the longevity and optimal performance of the Seepex MD0005-24 Rotor, consider the following maintenance tips:

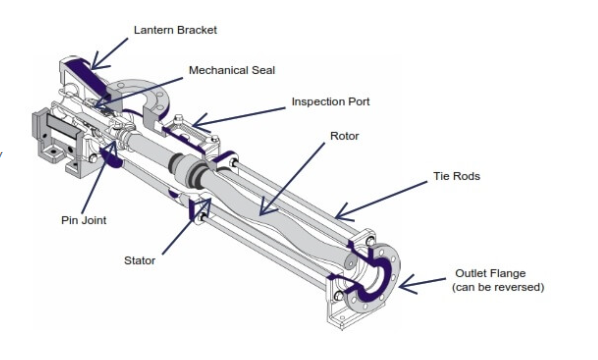

- Regular Inspections: Routinely check the rotor and stator for signs of wear or damage. Early detection of issues can prevent more significant problems down the line.

- Proper Lubrication: Ensure that the rotor is adequately lubricated, as this will reduce friction and wear during operation.

- Monitor Operating Conditions: Keep an eye on the temperature and pressure conditions during operation. Extreme conditions can adversely affect the rotor’s performance.

- Clean the System: Regularly clean the pumping system to prevent the buildup of debris and contaminants that could damage the rotor or impair its function.

- Follow Manufacturer Guidelines: Always adhere to the manufacturer’s guidelines for maintenance and operation to ensure the best performance and extend the life of the rotor.

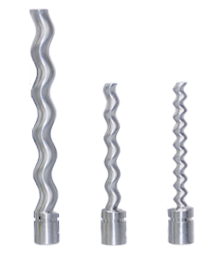

Features of the Seepex MD0005-24 Rotor

The Seepex MD0005-24 Rotor is engineered to meet the demands of various applications. Here are some of its notable features:

- Material Composition: The rotor is typically made from high-quality materials such as stainless steel or other corrosion-resistant alloys. This ensures durability and resistance to wear and tear, especially when handling abrasive or corrosive fluids.

- Precision Engineering: The rotor is manufactured with precision to ensure a perfect fit within the stator. This tight tolerance is crucial for maintaining efficiency and minimizing leakage.

- Versatile Applications: The MD0005-24 Rotor is designed for a variety of applications, including the transfer of viscous liquids, slurries, and even shear-sensitive fluids. Its versatility makes it suitable for industries ranging from pharmaceuticals to municipal wastewater.

- Enhanced Performance: The design of the rotor allows for efficient fluid displacement, which translates to lower energy consumption and reduced operational costs. This is particularly beneficial in processes where energy efficiency is a key consideration.

people also ask

Fill up and submit the below inquiry form, or directly write us an email: info@pumpvv.com