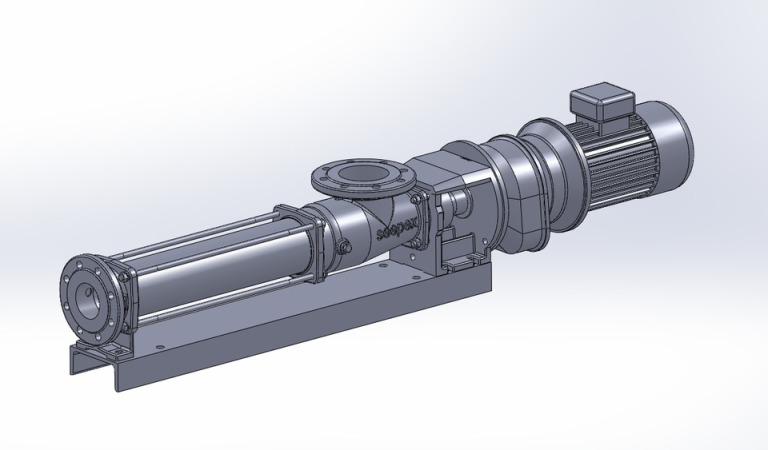

Parameters

| Model | BN52-6L | Voltage | 380V |

| Impeller structure | Single impeller | Conveying medium | Sludge and sewage |

| Pump shaft position | Horizontal | Drive mode | Electric |

| Lift | 60m | Flow rate | 52m3/h |

| Pressure | 0.6Mpa | Weight | 49kg |

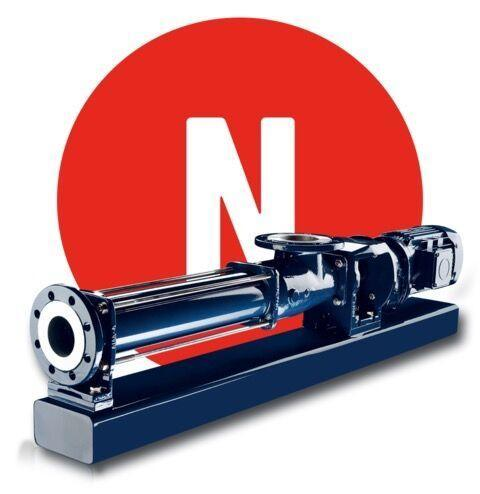

Introduction

The flow rate of Seepex BN52-6L is stable and will not pulsate due to changes in the properties of the medium. At the same time, since there are no easily worn parts such as pistons and cylinders, the maintenance cost is low and the service life is long. By changing the speed of the rotor, the flow rate can be easily adjusted continuously to meet the needs of different process conditions.

The volume cavity formed between the spiral blades on the rotor and the inner wall of the stator can continuously convey the liquid along the axial direction. The rotation of the rotor forms a pressure difference inside the stator to drive the liquid to flow.

BN52-6L performs well in conveying various viscous media containing solid particles. In the pharmaceutical industry, it can reliably transport various viscous pharmaceutical raw materials; in the food industry, it can be used to transport various highly viscous materials such as jams and syrups; in the chemical industry, it excels at handling chemicals containing solid particles.

people also ask

Fill up and submit the below inquiry form, or directly write us an email: info@pumpvv.com