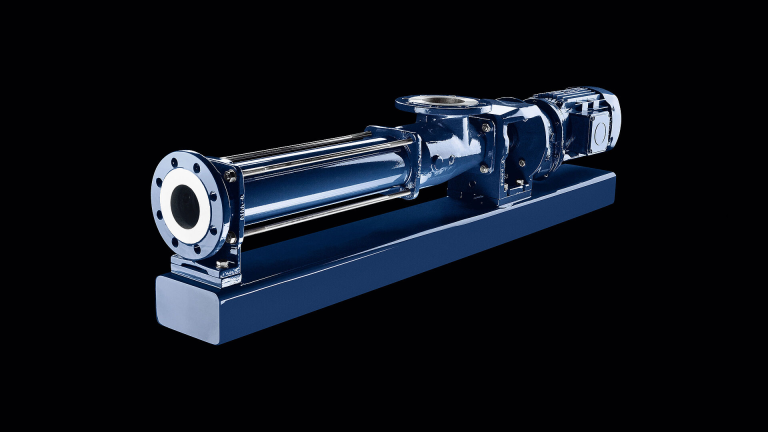

Design Features

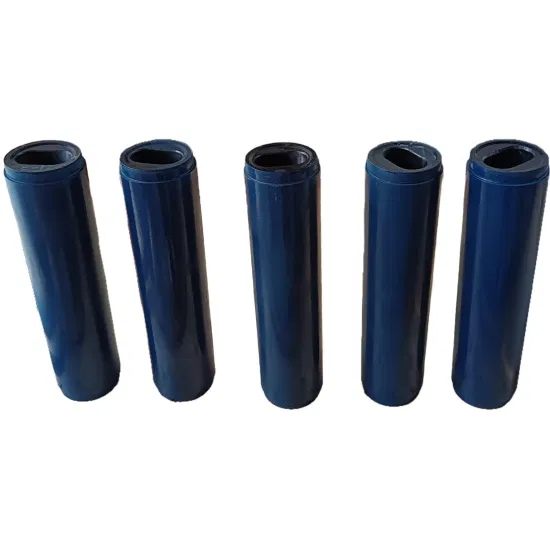

The seepex BN52-6L stator is made of high-quality materials and is designed to provide excellent wear and corrosion resistance. The design of this stator usually includes an efficient screw conveying system that can effectively handle a variety of viscous fluids. Its compact structure makes it easy to install in environments with limited space, making it widely used in many fields such as chemical industry, food processing and sewage treatment.

Working principle

The basic working principle of the seepex BN52-6L stator relies on its unique screw conveying structure. During the operation of the pump, the driver conveys the fluid into the cavity of the stator through the rotor. The fluid is subjected to external forces in the stator and is pushed along the direction of the spiral groove, thereby achieving continuous and efficient flow.

Application areas

In the chemical industry, the seepex BN52-6L stator is used to convey a variety of chemicals, especially those with high viscosity and complex properties. Due to its corrosion resistance, this stator can operate stably in high temperature and corrosive environments, ensuring the safety and continuity of the production process.

In the food industry, the seepex BN52-6L stator also plays an important role. It can effectively handle various food ingredients, such as sauces, syrups and dairy products, ensuring that there is no pollution during the production process and meeting food safety standards. In addition, its efficient conveying capacity can significantly improve the operating efficiency of the production line.

Wastewater treatment is another field where the seepex BN52-6L stator is widely used. In wastewater treatment, the fluid usually contains a large amount of solid particles. The design of the stator can effectively meet this challenge and achieve fast and efficient sewage transportation and treatment to meet environmental protection requirements.

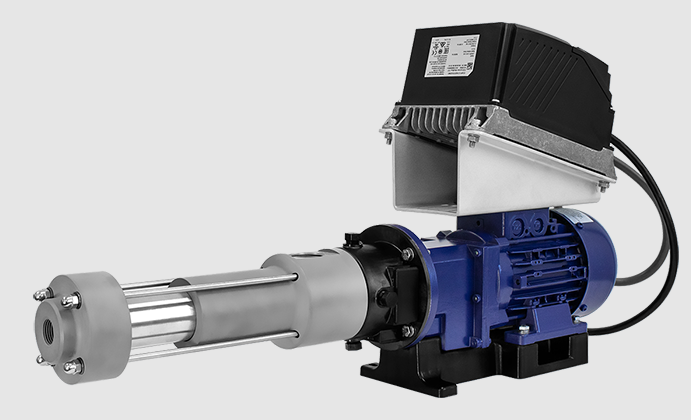

Performance advantages

The seepex BN52-6L stator has shown significant advantages in improving the overall performance of the pump. First of all, the structural design of the stator can effectively reduce the stagnation time of the liquid in the pump and promote the uniform flow of the fluid.

The wear resistance of the seepex BN52-6L stator enables it to maintain excellent working performance even under high load conditions. After long-term use, its wear rate is extremely low, reducing maintenance costs and equipment downtime.

people also ask

Send Your Enquiry :