[wpseo_breadcrumb]

Design and Construction of BN10-6L Stator

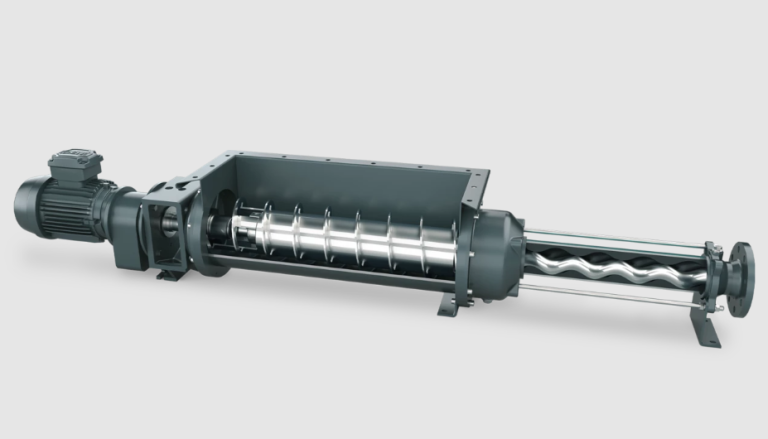

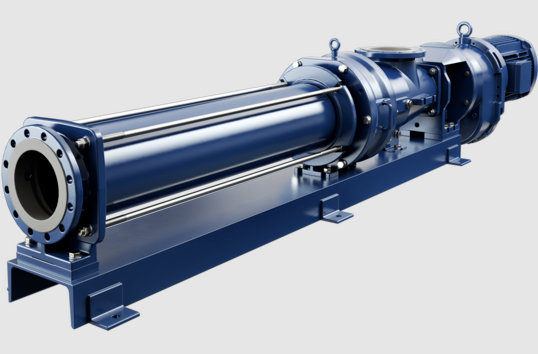

The Seepex BN10-6L stator is one of the core components of the Seepex screw pump. Its main function is to work with the rotor to form a sealed delivery chamber. The BN10-6L stator is made of high-strength polyurethane material, which has excellent wear resistance and corrosion resistance and can maintain stable performance under various harsh conditions.

- Material Advantages

The material selection of the BN10-6L stator is crucial. High-performance polyurethane not only provides good wear resistance, but also has good elasticity, which helps to form a tight fit with the rotor. This highly adaptable material enables the BN10-6L stator to easily handle high-viscosity liquids, reducing energy consumption and improving the efficiency of the pump. - Fluid Dynamics Design

The design of the BN10-6L stator takes into account the principles of fluid dynamics, optimizes the liquid flow path, and reduces flow resistance. This design not only improves the overall efficiency of the pump, but also reduces the energy consumption of the pump in long-term operation, thereby saving operating costs for the company.

Application areas

The Seepex BN10-6L stator has a wide range of applications in multiple industries, and the following are some key areas:

- Chemical industry

In the chemical industry, the delivery of liquids often involves high viscosity and corrosive liquids. Seepex’s screw pumps combined with the BN10-6L stator make the delivery of these liquids safer and more efficient. In addition, its chemical resistance allows it to handle a variety of chemicals and meet strict safety and environmental standards. - Food and beverage industry

In the food and beverage industry, due to the extremely high requirements for hygiene and safety, the pumps used and their components must meet strict standards. The material selection and design of the BN10-6L stator follow the relevant regulations for food safety, making it more widely used in this industry. - Pharmaceutical industry

The pharmaceutical industry has more stringent requirements for equipment, especially for the safety and cleanliness of materials. This series of Seepex products can meet the pharmaceutical industry’s requirements for precision and hygiene, so its application in this industry is becoming more and more common.

people also ask

Send Your Enquiry :