[wpseo_breadcrumb]

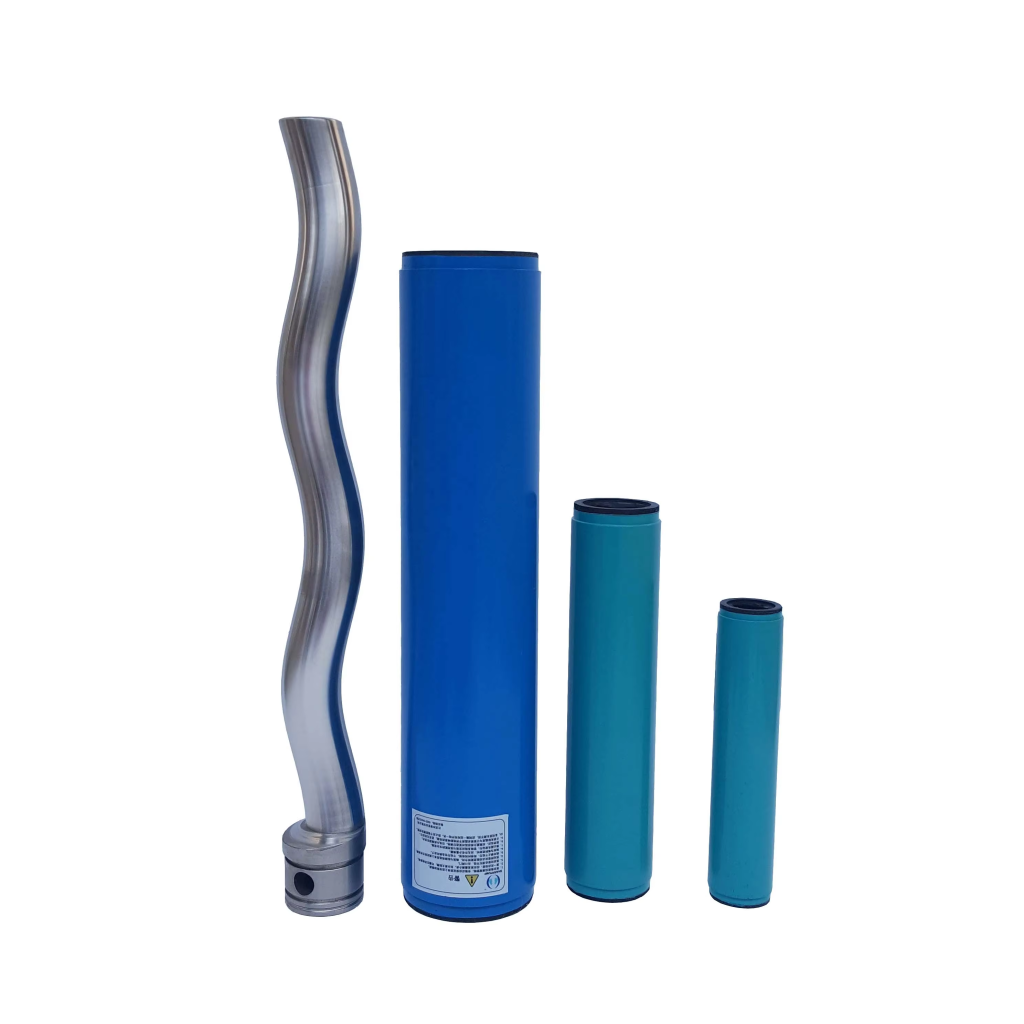

Structure and function of seepex BN17-6L stator

The seepex BN17-6L stator is a static component designed for pumps and is usually used in conjunction with a rotor. Its main function is to help the rotor move effectively in the liquid by providing a sealed environment. The stator is usually made of high-quality materials to ensure its durability and corrosion resistance.

Its unique shape and material selection enable the seepex BN17-6L stator to maintain excellent performance under various working conditions. For example, when handling viscous liquids or fluids containing solid particles, the stator design ensures smooth liquid flow while reducing wear and extending the service life of the pump.

Performance advantages

The main advantage of using the seepex BN17-6L stator is its excellent fluid dynamics. The design of the stator is precisely calculated, and when combined with the rotor, it can achieve uniform fluid delivery and reduce stagnation in the pump cavity. This not only improves the efficiency of the pump, but also reduces energy consumption, which meets the requirements of modern industry for energy conservation and emission reduction.

In addition, the seepex BN17-6L stator has a long service life. Designed to reduce wear, it can maintain good performance even in high-load and high-frequency working environments. This reliability allows companies to reduce maintenance frequency and downtime, thereby improving production efficiency.

Industry Applications

The seepex BN17-6L stator has found its place in many industries. First, in the chemical industry, the corrosion resistance of the seepex BN17-6L stator enables it to handle a variety of chemical media. When producing polymers, coatings or detergents, the stator ensures stable fluid delivery and ensures production continuity and safety.

In the food and beverage industry, the seepex BN17-6L stator‘s non-polluting characteristics and easy cleaning advantages make it an ideal choice for food processing equipment. The stator not only ensures efficient delivery, but also meets food safety standards to ensure product quality.

The pharmaceutical industry has very strict requirements for equipment, and the seepex BN17-6L stator is widely used in pharmaceutical production due to its reliability and hygiene. Its efficient fluid delivery capability can ensure the precise proportion of drugs, improve production efficiency, and meet the precision requirements of drug production.

people also ask

Send Your Enquiry :