Parameters

- Pump shaft position: horizontal

- Voltage: 380V

- Flow rate: 17m³/h

- Drive mode: electric

- Transport medium: sludge and sewage

- Model: BN17-6L

- Lift: 60m

- Working temperature: 40℃

- Application scope: fluid transportation

- Weight: 75kg

- Speed: 330RPM

- Maximum working pressure: 0.6MPa

- Material: 304 316

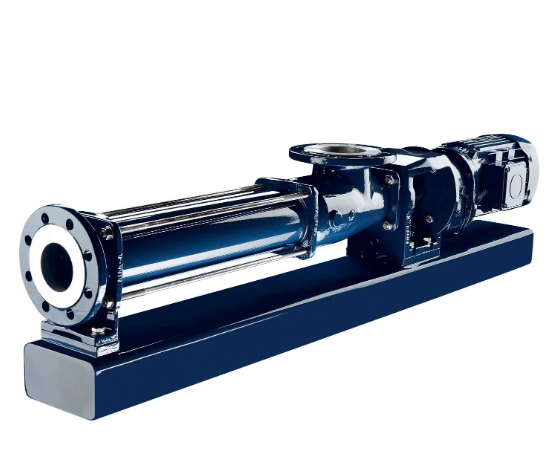

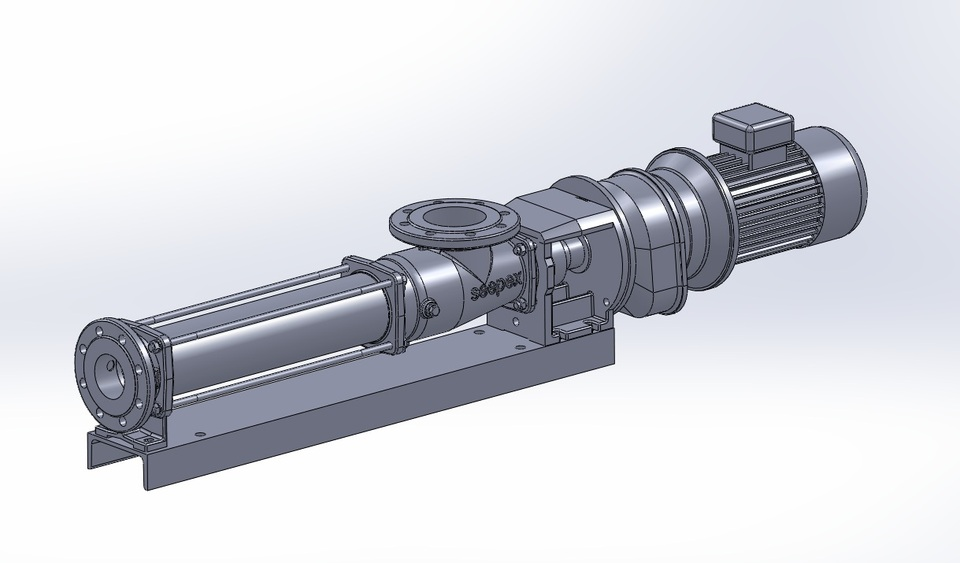

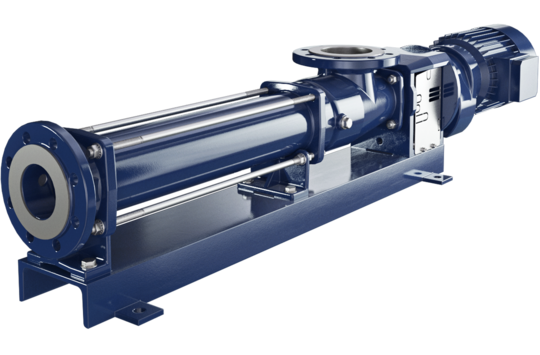

Introduction

Advanced rotor and stator design is adopted, which can reliably convey various viscous media containing solid particles. The volume cavity formed between the spiral blades on the rotor and the inner wall of the stator can continuously convey the liquid along the axial direction. The rotation of the rotor forms a pressure difference inside the stator to promote the flow of liquid.

Compared with traditional gear pumps or piston pumps, seepex BN17-6L has many advantages. First of all, it has a stable flow rate and will not pulsate due to changes in the properties of the medium. At the same time, since there are no easily worn parts such as pistons and cylinders, the maintenance cost is low and the service life is long. In addition, the BN17-6L has excellent self-priming performance, can handle media with high gas content, and can operate smoothly even in negative pressure environments.

Another feature worth mentioning is that the seepex BN17-6L is very flexible in flow regulation. By changing the speed of the rotor, the flow rate can be easily adjusted continuously to meet the needs of different process conditions.

people also ask

Send Your Enquiry :