Parameters

| Brand: seepex | Drive mode: electric | Performance: wear-resistant | Conveying medium: sewage pump |

| Pump shaft position: horizontal | Number of impellers: single stage | Flow rate: 150-200 | Lift: 60 |

| Speed: 298 | Suction diameter: DN200 | Discharge diameter: DN200 | Efficiency: 98% |

| Output flow: 200 | Power: 22kW | Weight: 300 | Working temperature: normal temperature |

| Shaft power: 22 | Application: chemical pump | Material: stainless steel | Model: BN200-6L |

Introduction

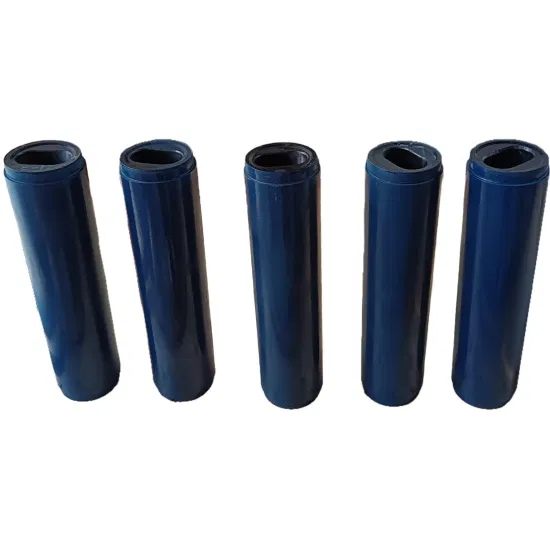

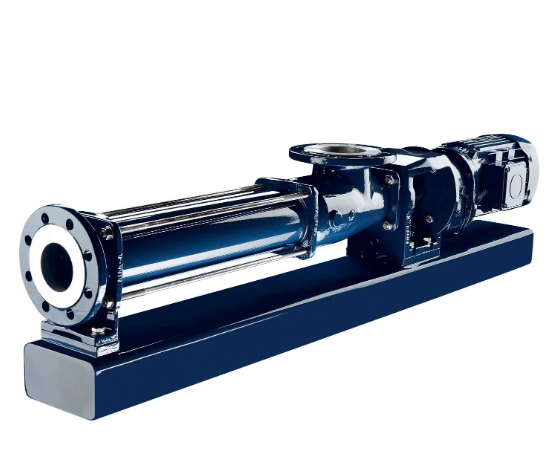

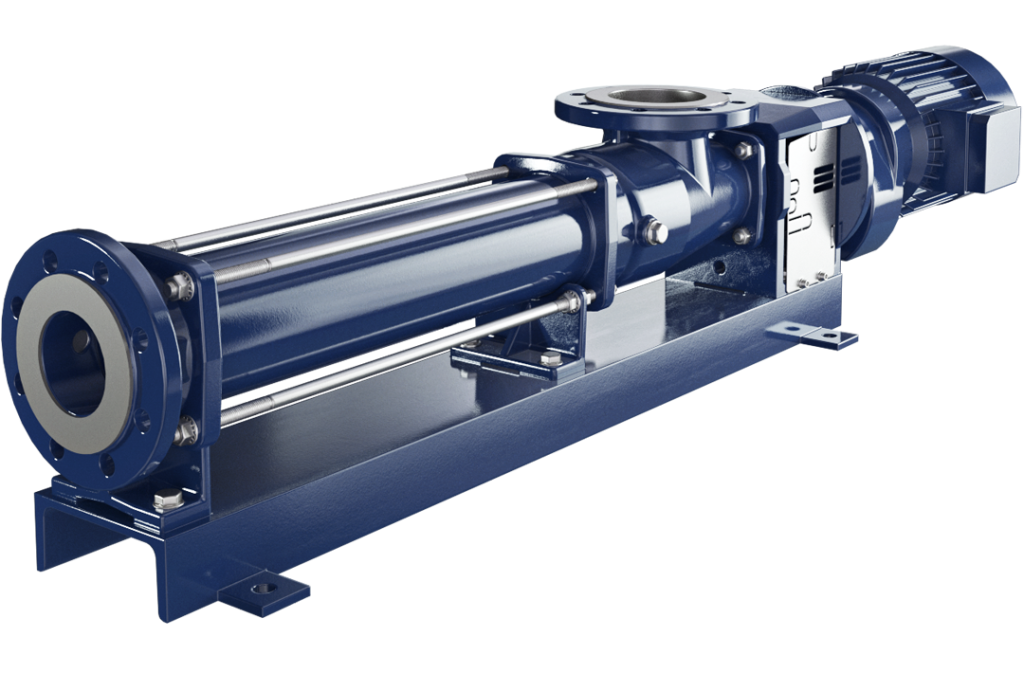

The core components of the Seepex BN200-6L include the rotor and stator. The design of these two is the key to its efficient pumping. The rotor adopts a spiral shape, which can effectively drive the fluid along the pump body, while the internal design of the stator perfectly matches the rotor to form a precise closed cavity.

The rotating action of the rotor drives the liquid flow, and its unique design allows the Seepex BN200-6L to maintain stable delivery efficiency when handling non-Newtonian fluids, suspensions or other high-viscosity fluids.

Users can adjust the operating parameters of the BN200-6L according to different process requirements to ensure the best pumping effect. This flexibility allows it to maintain high efficiency when facing a variety of production tasks.

The maintenance operation of the Seepex BN200-6L is also very simple. Thanks to its modular structure, users can easily replace the rotor and stator, greatly reducing maintenance time and cost. Whether it is daily inspection or troubleshooting, it can ensure the efficient operation of the pump, thereby maintaining the continuity of the production process.

people also ask

Send Your Enquiry :